17

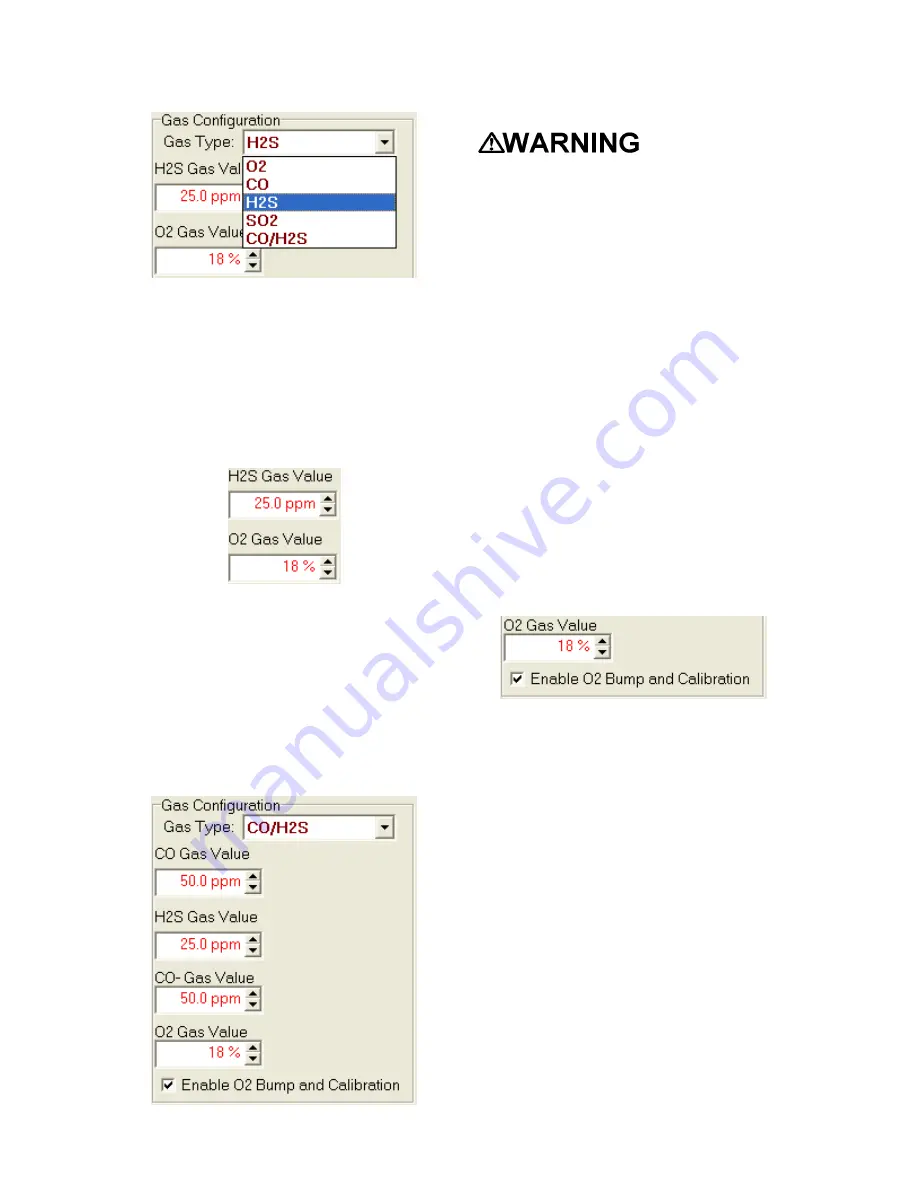

To change the gas type, click on the down

arrow to the right of the gas setting and

select the new gas type.

Once the gas type is chosen, enter the

calibration gas composition, including the

values for any toxic gases in the cylinder in

terms of parts-per-million (ppm) and the

oxygen level in terms of percent volume

(%). To change a gas value use the arrows

to the right of the gas value input box to

increase or decrease the value until it

matches the value given on the gas

cylinder.

Since a common calibration gas mixture

includes CO and H

2

S, a CO/H

2

S option is

available that offers distinct settings for CO

and H

2

S. This allows the dock to process

CO, CO- and H

2

S units without changing the

gas setting.

Note: Due to cross-sensitivity issues,

CO+ detectors must be calibrated with

CO calibration gas only. A CO+ detector

placed in a dock that is configured for

CO/H2S will automatically fail to process.

The IQ System will automatically fail any

detector that is processed when the

calibration gas type fails to match the

sensor type.

Calibration values

shown in the Gas Value column must

match those appearing on the calibration

gas cylinder(s) that will be used to

calibrate the detector. Non-matching

calibration gas and calibration gas value

settings will lead to inaccurate and

potentially dangerous readings.

Special Instructions: Gas

Configuration, Oxygen Detectors

An oxygen detector can be processed by

the IQ Express in a fresh air atmosphere

without the use of calibration gas, but an

optional bump test is available to verify

oxygen sensor response. The O2 Bump

and Calibration is automatically enabled at

the factory. If the user wishes to bypass the

oxygen bump test, the O2 Bump and

Calibration option can be disabled by

deselecting the “Enable….: check box at the

bottom of the Gas Configuration settings. .

Each calibration gas type includes an

oxygen setting that should reflect the

amount of oxygen in the calibration gas

cylinder (typically 18%).

With the O2 Bump and Calibration option

enabled, when an oxygen detector is placed

in the dock, the system will proceed with an

oxygen bump test based on the O

2

gas

value that has been entered. If the bump

test fails, the dock will show a warning on

the screen that the instrument has failed the

test.

A special case exists when a cylinder of

0.0% oxygen calibration gas is connected to

the dock. If the O2 Gas Value is set to 0.0%

oxygen and the instrument fails the bump

test, it will automatically attempt a full zero

calibration at 0.0% oxygen.

For all other levels of calibration gas

(>0.0%), the oxygen bump test is the only

test available. The zero calibration of the

oxygen sensor is only available with

calibration gas containing 0.0% O

2

.

To disable the O2 Bump and Calibration

deselect the option.