Troubleshooting

RTCSmp Built-In Temperature Controlled Hold-Line

Part # 4532287 Rev 2 (1/20/14)

25

10.3

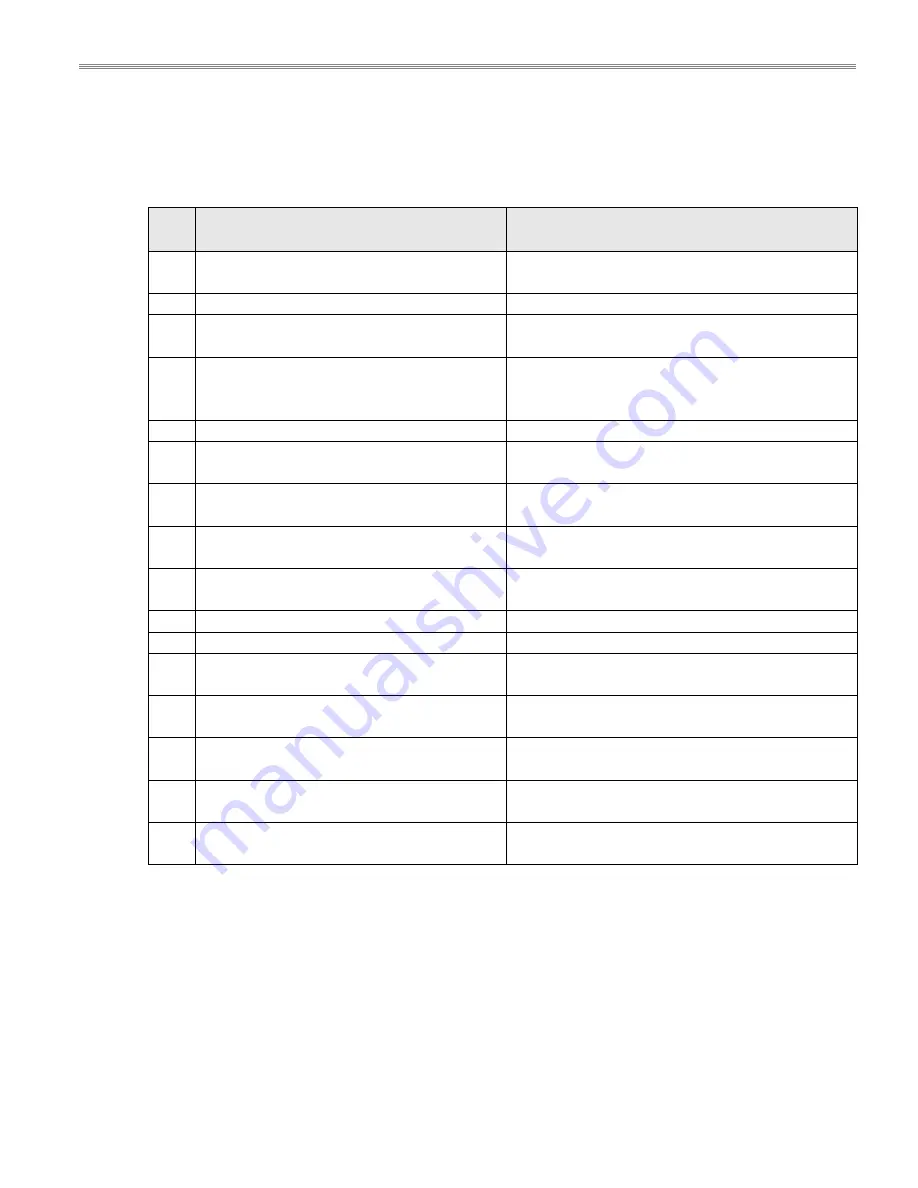

Troubleshooting with Error Codes (for Service Technicians)

To obtain the internal data for troubleshooting, you need an IR Adapter, proper connectors, and software. The

table below is a reference guide. For further information and assistance, please contact Garland Technical Service.

Error

Code

Reason

Things To Check

E01

Hardware overcurrent or coil is not

connected(1)

Check the Chafing Dish or Pan material, Check wiring.

E02

Software overcurrent (1)

Check the Chafing Dish or Pan material.

E03

Heat sink overtemperature

T > 85°C (1)

Check installation (Airflow).

E04

Empty cooking detektor

Total failure of the sensor unit or sensor unit not

connected (1)

Check sensor unit.

Set point: 1080Ohm at 25°C

E05

Potentiometer defect or not connected (1)

Check the potentiometer wiring.

E06

Temperature inside the generator too high.T >

80°C (1)

Check installation (Airflow).

E10

Reduction KK temperature

T > 75°C (2)

Check installation (Airflow).

E12

Reduction internal temperature

T > 70°C (2)

Check installation (Airflow).

E20

Faulty or not connected heat sink temperature

sensor (1)

Contact Garland.

E21

Board sensor defect (1)

Contact Garland.

E24

Temperature processor central unit > 100°C (1) Check installation (Airflow).

E30

Heat retention plate sensor 1 over temperature

or defect (1)

Check warming process. Check sensor 1 Set point:

1080Ohm at 25°C

E41

Heat retention plate sensor 2 over temperature

or defect (1)

Check warming process. Check sensor 2 Set point:

1080Ohm at 25°C

E42

Heat retention plate sensor 3 over temperature

or defect (1)

Check warming process. Check sensor 3 Set point:

1080Ohm at 25°C

E43

Reduction KK temperature

T > 75°C (2)

Check installation (Airflow).

E01

Hardware overcurrent or coil is not

connected(1)

Check the Chafing Dish or Pan material, Check wiring.

(1) Power supply is interrupted immediately.

(2) The unit works with reduced power.