13–8–609 Page 19

Pressure And Temperature Digital Readouts –

These readouts normally indicate pressure at the mini-

mum pressure check valve and temperature at the air

end discharge. See “High Air Temperature LED”, page

18, for a description of readout action during a high

temperature condition.

Alternately, these readouts can be selected to display

oil reservoir pressure and separator air temperature. To

obtain such display while the compressor is running,

simply press the operating mode button that corre-

sponds to the current operating mode of the unit. (For

Example: If the unit is operating in “AUTO LEAD”

mode, press the “AUTO LEAD” button.) This will cause

the readout to display the alternate parameters. This al-

ternate display mode is indicated by illuminated deci-

mal points in the lower right hand corner of each dis-

play. After releasing the button, the display will revert

to its normal mode in 5 seconds.

The digital readouts are also used to display error mes-

sages. These error messages correspond to various

indications concerning condition of pressure and tem-

perature sensors and EMERGENCY STOP condition.

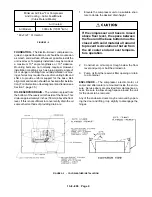

DEFINITIONS OF ERROR MESSAGES – Refer to

the chart in FIGURE 4–4 below for definitions. An error

message will stop the compressor, if running, and pre-

vent it from restarting. The failed sensor must be re-

placed to clear the error.

Any condition requiring the control panel to be reset will

be indicated by a flashing “STOP/RESET” LED. If all

readouts and LED’s are flashing, a power interruption

has occurred, requiring the control panel to be reset.

Programming The Load–Unload Pressure Set-

points – Programming of the Load and Unload Pres-

sure setpoints can only be accomplished with the unit

not running.

Step 1:

Stop the compressor and remove all power

from the unit by opening main disconnect.

Electrical shock can cause injury or

death. Open main disconnect, tag

and lockout power supply to the start-

er and any other circuits before work-

ing inside the control box.

Step 2:

Turn the “Setup” switch located on the con-

troller circuit board (inner side of control box

panel) to the “+” position. Close the control

box panel and restore power.

This switch is provided to prevent un-

authorized programming of the set-

points. If this level of security is not

required, the “Setup” switch can be

left in the “+” position, eliminating

Steps 1 and 2.

Step 3:

With the unit already in the STOP/RESET

condition, press the “STOP/RESET” button

a second time. This puts the controller in pro-

gram mode. The displays will read as follows:

Pressure: the current unload setpoint (adj.

58–175 psig, 4.0 to 12.1 Bar)

Temperature:

indicates that the

pressure value is the “un–

load” value.

Pressure Readout

Temperature Readout

Error # Meaning

Error # Meaning

E01

Failure of Final Discharge Pressure Sensor

E01

Failure of Compressor Temperature Sensor

E02

Failure of Oil Sump Pressure Sensor

E02

Failure of Separator Temperature Sensor

E03

Failure of Both Pressure Sensors

E03

Failure of Both Temperature Sensors

E04

EMERGENCY STOP

FIGURE 4–4 – DEFINITION OF ERROR MESSAGES

Содержание ELECTRA-SCREW EBE DH-15 HP

Страница 10: ...13 8 609 Page 2 200EBE797 Ref Drawing FIGURE 1 2 PACKAGE MINIMUM PRESSURE CHECK VALVE SEPARATORS OIL FILTER...

Страница 11: ...13 8 609 Page 3 200EBE797 Ref Drawing FIGURE 1 3 PACKAGE OIL LEVEL GAUGES STARTER CONTROL BOX AIR FILTER...

Страница 14: ...13 8 609 Page 6 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Страница 15: ...13 8 609 Page 7 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Страница 32: ...13 8 609 Page 24 FIGURE 4 10 WIRING DIAGRAM DUAL CONTROL 218EBE546 Ref Drawing...

Страница 33: ...13 8 609 Page 25 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 220EBE546 Ref Drawing...

Страница 51: ......