SMART CUT 1000

19

4.2 Cutting Preparation

1)

Tightly connect the power cable to electrical socket outlet (the input voltage, refer to the section 2 technology

parameters)

2)

Tonnect the air pipe to the air supply equipment, the earth cable to the workpiece

3)

Turn on the power switch ,the power source lamp on.

4)

Turn the RUN/SET switch to SET position, the air flow, then regulate the air pressure to 3.5-6bar

5)

Turn the RUN/SET switch to RUN position, regulate the current after the flow stops.

6)

Now all the preparation done .

4.3

Normal Cut

Normal Cut

Normal Cut

Normal Cut

1.

Normal Cut

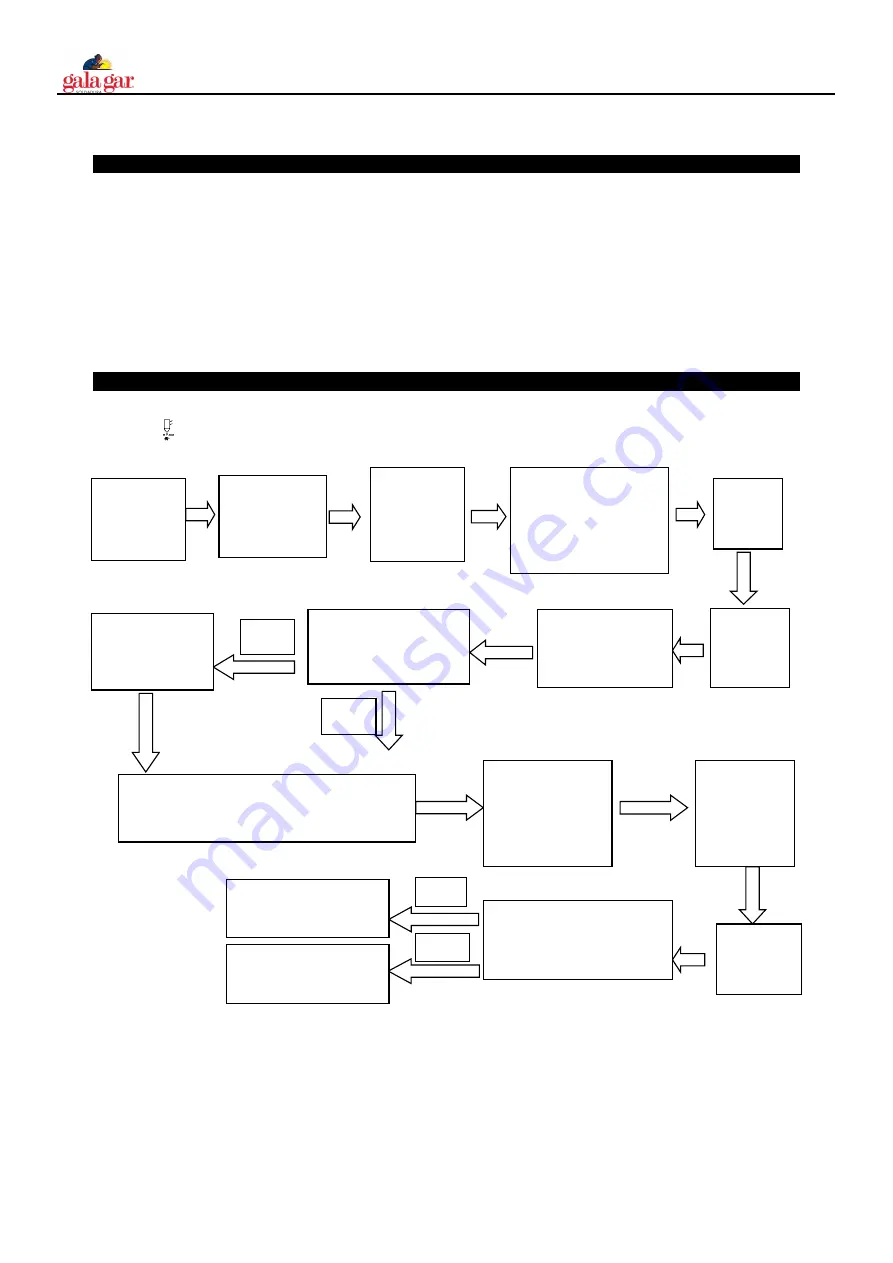

Fig 4.2 the working flow chart

<1>:seting time value equal for welding current.

Turn on the

power source

Automatic gas

test for 10S

Loose the

cutting torch

trigge

.

Pre-gas

for 1s

The torch move away

the workpiece, then ,

the arc stops

Automatic

examine for 5s

After Initialization and the

fan stop, press on the torch

trigger

Ignite the

pilot arc,

the max.

time is10s

Post-gas

If the tip touch the

workpiece and the current

higher than 40A, isn’t it ?

Shift to the workpiece,

the pilot arc change

into cutting arc

Yes

No

The current will

down to 40A

Cutting

Is the torch trigger pressed on

again among the period of post-

gas ?

Yes

No

Restart and continue

working

Finish after post-gas for

seting time

<1>

Содержание 223001000C

Страница 26: ......

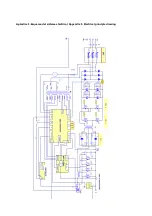

Страница 27: ...Apéndice 1 Esquema del sistema eléctrico Appendix 1 Electrical principle drawing ...

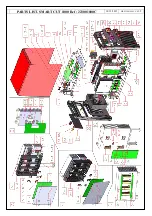

Страница 28: ...PARTS LIST SMART CUT 1000 Ref 223001000C 14 12 2015 HR 223001000C V0 1 2 ...

Страница 30: ......

Страница 31: ......