SMART CUT 1000

20

2.

Grid Cut

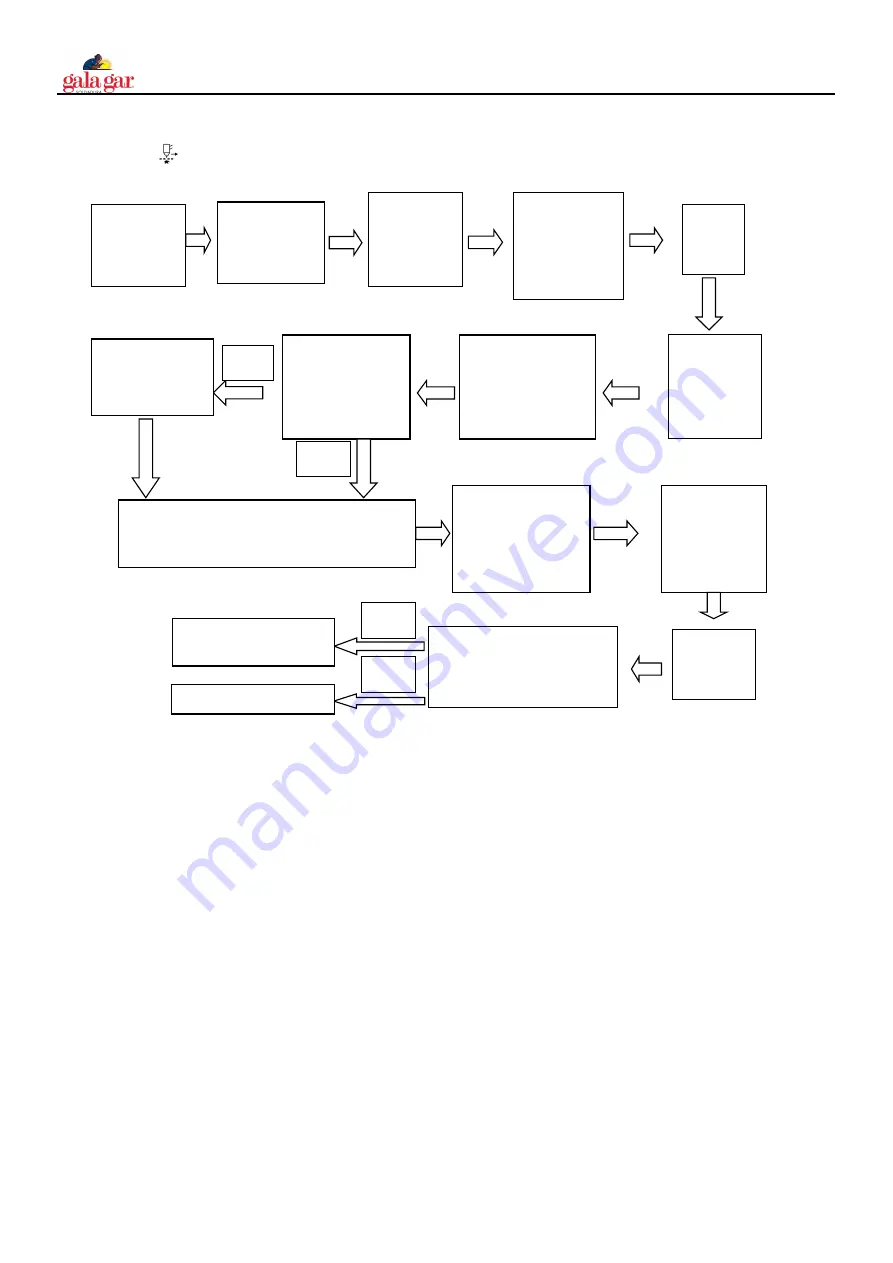

Fig 4.3 the working flow chart

Note:

Note:

Note:

Note:

1)

The alarm lamp on when cutting, it is needed to loose the switch of the torch until the alarm release, then press

on the switch to restart working.

2)

In the automatic gas test and examine, press on the cutting torch, there will no reflection.

3)

After a long usage, the surface of the electrode and nozzle will have Oxidation reaction. Please replace the

electrode and nozzle, For The alarm lamp will on when install the shield cup, and stop working

4)

It is forbidden to take down the fittings of the cutting torch when the trigger is pressed.

5)

If the cutting current is higher than 40A, when the tip touch the workpiece, the current will down to 40A in oder

to protect the tip.

6)

Among the period of post gas, if you press the trigger for a long time, the arc restars; if you press and loosen

the trigger quickly, the gas stops, after it you can press the trigger for a long time to restart the machine as well.

Turn on the

power source

Loose the

cutting torch

trigger, the arc

stops

Pre-gas

for 1s

The torch move away

the workpiece, then the

cutting arc change into

the pilot arc

Automatic

examine for 5s

After

Initialization and

the fan stop,

press on the torch

trigger

Ignite the

pilot arc, the

max. time

is10s

Post-gas

If the tip touch the

workpiece and the

current higher than

40A, isn’t it ?

Shift to the workpiece,

the pilot arc change

into cutting arc

Yes

No

The current will

down to 40A

Cutting

Is the torch trigger pressed on

again among the period of post-

gas ?

Yes

No

Restart and continue

working

Finish after post-gas for 15s

Automatic gas

test for 10S

Содержание 223001000C

Страница 26: ......

Страница 27: ...Apéndice 1 Esquema del sistema eléctrico Appendix 1 Electrical principle drawing ...

Страница 28: ...PARTS LIST SMART CUT 1000 Ref 223001000C 14 12 2015 HR 223001000C V0 1 2 ...

Страница 30: ......

Страница 31: ......