CA / CT SERIES

CAP600

Page 5 of 30

REV D July 2013

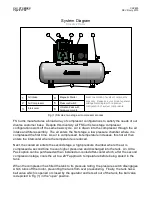

System Diagram

Simplex Units

1

2

3

4

5

6

Air Intake

Air Compressor

Intercooler

Magnetic Starter

Pressure Switch

Vibration Pads with

hardware mounts

1

Exact orientation of system components

may vary. Please see your model's general

arrangement diagram for a precise

configuration of system components.

6

2

3

4

5

Fig. (1) Simplex, two stage air compressor process.

FS Curtis manufactures a broad array of compressor configurations to satisfy the needs of our

diverse customer base. Despite this diversity, all FS Curtis two stage compressor

configurations work off the same basic cycle. Air is drawn into the compressor through the air

intake and filter assembly. The air enters the first stage, a low pressure chamber where it is

compressed the first time. As air is compressed, its temperature increases, this hot air then

enters the intercooler where the temperature is reduced.

Next, the cooled air enters the second stage, a high pressure chamber where the air is

compressed a second time to even higher pressures and discharged into the tank. An Ultra

Pack option can be purchased with an installed air-cooled after-cooler which, after the second

compression stage, cools the air to a 20°F approach temperature before being stored in the

tank.

When the compressor has filled the tank to its pressure rating, the pressure switch disengages

which turns off the motor, preventing the tank from over pressurizing. Finally, the tank has a

ball valve which is opened or closed by the operator and lets air out of the tank, the ball valve

is depicted in Fig (1) in the “open” position.