CA / CT SERIES

CAP600

Page

10 of 30

REV D July 2013

Acceptable Mounting

Unacceptable Mounting

•

Concrete Anchor Bolts

•

Threaded Rod or Floor Stud

•

Steel flooring or supports (provided unit

is bolted down and isolator pads are

used)

•

Skid Mounted

•

Unanchored

•

Bare Floor (no vibration pads)

Table (2) Compressor mounting methods

If you wish to utilize an installation method other than the approved methods described in

Table (2), please contact your local distributor. FS Curtis neither states as fact, nor implies

that the above list of Acceptable/Unacceptable mounting is all-inclusive. Contact your local

distributor for more information.

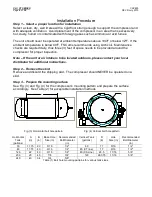

Step 4 – Install Vibration Isolator pads and mount the compressor

Exposure to excessive vibrations can significantly shorten the life of the compressor. FS

Curtis highly recommends mounting the unit on vibration isolator pads and the compressor

should NEVER be operated without being securely fastened to the ground.

Using a level, please check for proper alignment of the compressor. Uneven installation will

unbalance the compressor leading to excessive noise, vibrations, and wear. Place a steel

shim between the concrete and vibration pads and shim down as necessary for leveling. Level

the compressor so it can be bolted down securely. Before tightening the bolts, check to see

that all four feet are resting on the foundation. See fig (5) for mounting instructions for a floor

stud, and see fig (6) for mounting instructions for an anchor bolt.

FLANGE NUT

Leave loose & lock

with a back-up nut

RECEIVER FOOT

ISOLATOR BACKING

PLATE OR SHIMS IF

NECESSARY

ISOLATOR

ANCHORED

FLOOR

STUD

FLANGE NUT

Leave loose & lock

with a back-up nut

RECEIVER FOOT

ISOLATOR BACKING

PLATE OR SHIMS IF

NECESSARY

ISOLATOR

ANCHORED

FLOOR

STUD

Fig. (5) Anchored Floor Stud installation