CA / CT SERIES

CAP600

Page 6 of 30

REV D July 2013

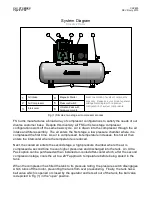

Duplex Units

1

2

3

4

5

6

Air Intake

Air Compressor

Intercooler

Alternator

Pressure Switch

Vibration Isolator pads

with hardware mounts

2

Exact orientation of your system's

components may be different from the

layout in the figure. Please see your model's

general arrangement diagram for a precise

configuration of system components.

1

1

2

3

3

4

5

5

6

Fig. (2) Duplex unit system diagram.

Refer to the simplex diagram for a description of the compression cycle.

Duplex units operate in much the same way as simplex units, only there are two compressors.

The key difference is in the pressure switch and starter. In a duplex unit, there are two

pressure switches, a “lead” pressure switch and a “lag” pressure switch set 10 psi lower than

the lead switch. The alternator utilizes both compressors to fill the tank. Once the tank

approaches the cutoff “lag” pressure, the alternator selects one compressor to be the “lag”

compressor and cycles it off, using only the “lead” compressor to provide the remaining

pressure. The alternator then cycles between both compressors, switching the “lead” and “lag”

compressor and ensuring roughly equal wear between them. If air usage exceeds the output

of a single compressor, the alternator utilizes both the “lead” and the “lag compressor to fulfill

operating conditions, once again cycling off the “lag” compressor when its cutoff pressure is

reached.