S70-101SM

Page 20

Frick XJS and XJF Rotary Screw Compressor

Service Manual

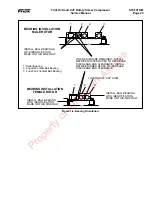

DISHCHARGE

BALL BEARING

INSTALLATION

TOOL

ROLLER

BEARING

DISCHARGE

CASING

8. Place discharge casing, with flange down, on work surface

and install two o-rings (23) and gas seals (24) in casing.

Ensure that spring pin (6, Figure 1-4) in each gas seal engages

oil hole (bore) in discharge casing.

GAS SEAL

O-RING

DISCHARGE

CASING

9. Using Discharge Ball Bearing Installation Tool, install new

roller bearing (25) into each bore in discharge casing.

10. Rebalance rotors* if possible. Install male rotor into rotor

casing, with threaded end of rotor facing discharge end of

compressor. Ensure that all parts have been thoroughly cleaned

with OSHA approved, nonflammable degreaser and coated

with a thin film of clean refrigerant oil.

* Balancing specifications:

95mm male

.036 in.-oz.

95mm female

.028 in.-oz.

120mm male

.072 in.-oz.

120mm female

.055 in.-oz.

11. Install female rotor into rotor casing, with threaded end of

rotor facing discharge end of compressor. Ensure that all parts

have been thoroughly cleaned with OSHA approved, non-

flammable degreaser and coated with a thin film of clean

refrigerant oil.

12. Place new o-ring (45) in groove in discharge end of rotor

casing; apply a light coating of grease to keep o-ring in place.

Align discharge casing with rotor casing, ensuring that dowel

pins (46 and 58) engage dowel pin holes; secure discharge

casing with four capscrews (1 and 5, Figure 1-4) evenly

spaced around casing flange. Tighten capscrews to a torque

value of 58 foot-pounds (79 Nm).

NOTE: If air tool is not available, a 12 mm "T" handle

can be used to pull and push rotors.

13. Connect Air Cylinder Tool to drive end of compressor.

Thread two 12mm guide pins (3

1

/

2

-

inches long for male

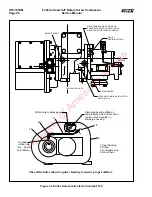

COMPRESSOR

DISCHARGE END

MALE ROTOR GUIDE PIN

MEASURING

ROTOR-TO-CASING

CLEARANCE

rotor and 5

1

/

2

-inches long for female rotor) into discharge end

of rotor shafts. Set up a dial indicator at discharge end of

compressor, with indicator resting against end of male rotor

guide pin. Using Air Cylinder Tool, with pressure set 100 psi

max. male side – 100 psi max. female side, pull rotor back and

set indicator to zero. Push shaft forward and record measure-

ment (refer to Table 1.1). Repeat procedure for female rotor.

Rotor-to-casing clearance should be .025-inch to .031-inch. If

rotor-to-casing clearance is greater than .031, look for a

binding o-ring between rotor casing and discharge casing

flanges, or metal or dirt contamination between flanges.

COMPRESSOR

DRIVE END

AIR CYLINDER

TOOL

Property of American Airlines