S70-101SM

Page 17

Frick XJS and XJF Rotary Screw Compressor

Service Manual

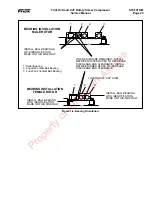

20. Push stepper piston against spring and remove 8mm screw

threaded into slide stop (25), through oil drain hole; with hand

pressure against piston, remove T-wrench.

STEPPER PISTON

8MM T-WRENCH

21. With new o-ring (32) on slide stop cover (30), secure

cover to gear housing with capscrews (7, Figure 1-2). Tighten

capscrews to a torque value of 58 foot-pounds (79 Nm).

22. Install drain plug (24, Figure 1-4).

23. Install coupling guard, if previously removed.

24. Evacuate compressor and oil separator. (Refer to S70-101 IOM.)

1.4 ROTORS AND BEARINGS. This procedure provides

the information necessary for qualified personnel to replace

the discharge bearing assembly, including required compres-

sor disassembly.

1.4.1 ROTORS AND BEARINGS – REMOVAL. Rotors

and bearings removal shall be accomplished as follows:

NOTE:

Index numbers refer to Figure 1-2, unless other-

wise noted.

1. Remove shaft seal. (Refer to paragraph 1.1.2)

2. Remove jackshaft and gears. (Refer to paragraph 1.2.1)

3. Remove slide valve and stop. (Refer to paragraph 1.3.1)

4. Remove capscrews (8, Figure 1-4) securing outlet bore

cover (39) to discharge casing (43); remove outlet bore cover

with o-ring (27) and nine compression springs (37).

5. Remove capscrews (8, Figure 1-4) securing outlet bore

cover (41) to discharge casing; remove outlet bore cover with

o-ring; remove spring washer (42), or wave spring on newer

units.

6. Remove male distance sleeve (38) and female distance

sleeve (44).

7. At nondrive end of male and female rotor shafts (47), bend

one tab back on each lockwasher (35) that was previously

bent into recess of its respective locknut (36).

8. While holding male rotor stationary and with 12mm T-

wrench threaded into drive end of male rotor shaft, remove

locknut (36) using Spanner Wrench; remove and discard

lockwasher (35).

9. While holding female rotor stationary and with 12mm T-

wrench threaded into drive end of female rotor shaft, remove

locknut (36) using Spanner Wrench; remove and discard

lockwasher (35).

11. Remove two capscrews (1 and 5, Figure 1-4) from

opposite sides of discharge casing and install two 12mm

guide pins (3

1

/

2

-inches and 5

1

/

2

-inches long); remove rest of

capscrews securing discharge casing to rotor casing (3).

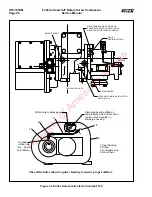

10. Install an eyebolt into top of discharge casing; attach

suitable lifting sling to hoist with adequate capacity to

support weight of discharge casing.

EYEBOLT

D I S C H A R G E

CASING

XJS and XJF 95 discharge casing

weigh 90 lb. (41kg); XJS and XJF

120 weigh 115 lb. (53 kg). Ensure

that rigging is of adequate capacity

and properly attached before lifting

compressor.

WARNING

Property of American Airlines