S70-101SM

Page 9

Frick XJS and XJF Rotary Screw Compressor

Service Manual

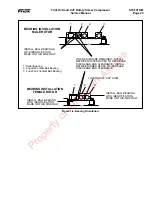

Figure 1-3. Using Clamp Collar Installation Tool.

1.2 JACKSHAFT AND GEARS. This procedure provides the

information necessary for qualified personnel to replace the

jackshaft bearings, including required compressor disassembly.

1.2.1 JACKSHAFT AND GEARS – REMOVAL. Jackshaft

removal shall be accomplished as follows:

NOTE: Index numbers refer to Figure 1-2, unless other-

wise noted.

1. Place suitable drain pan under compressor oil drain, remove

drain plug located at the center bottom on the gear cover and

drain plug (24, Figure 1-4).

2. Remove shaft seal. (Refer to paragraph 1.1.2.)

3. Place suitable drain pan under slide stop cover (30, Figure

1-4) and remove capscrews (7) securing slide stop cover to

gear cover (2, Figure 1-4); remove slide stop cover and o-ring

(32, Figure 1-4), while holding stepper piston in by hand.

8MM T-WRENCH

STEPPER PISTON

5. Remove stepper piston with glyd-rings (10 and 28, Figure

1-4) and o-rings (11 and 29, Figure 1-4). If glyd-rings and o-

rings are to be replaced, cut glyd-rings off of stepper piston

using knife and remove and discard o-rings.

4. Thread 8mm T-wrench into stepper piston and push piston

in against spring force. With finger through oil drain hole (24,

STEPPER PISTON

Figure 1-4), push in against spring force and feel along bottom

of slide stop. When threaded hole in slide stop is located, insert

8mm screw (Frick p/n 111Q0740796) through oil drain hole

and thread into slide stop.

4

2

1

13

12

10

9

8

7

3

5

6

11

1. O-Ring

2. Carbon Face

3. Rotating Seal Seat Assembly

with shiny side of seat facing outward

4. O-Ring

5. Gear Cover

6. Four-Point Contact Ball Bearing

7. Clamp Collar Installation Tool

8. Shaft

9. Clamp Collar

10. Seal Seat Backup Ring

11. Seal Housing

12. Carbon Faced Seal Assembly

13. Strainer

Property of American Airlines