VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 16

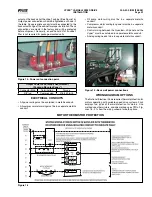

THE “TRAP” FIlTER

is standard on all Frick Vyper

™

units

that contain the Harmonic Filter. The trap filter is composed

of a series of capacitors, inductors, and resistors. The trap

filter is used to reduce the effects of the PWM switching

frequency of the filter (20kHz) on the AC line.

CONFIGURATION:

The Frick Vyper

™

is internally cooled with a factory calibrated

liquid cooling circuit which offers many advantages over tradi-

tional air-cooled systems. The liquid circuit provides precisely

controlled coolant temperatures to the heat generating com-

ponents and delivers coolant into locations that no air-over

fan could penetrate. The Vyper

™

liquid-cooling arrangement

performs independently of fluctuating ambient conditions. The

NEMA 4 Indoor-rated cabinet seals the internal electronics

and piping from corrosive refrigerant vapors while provid-

ing superior cooling for the internal electronic components.

Efficient liquid cooling also allows for smaller cabinet size

and longer component life than traditional air-cooled units.

Either plant condenser water or a facility supplied Glycol loop

subsequently removes the heat in the coolant via the heat

exchanger located at the back of the cabinet.

VYPER

™

COOlING lOOP

While the compressor is running, the Quantum

™

LX control

panel monitors the temperature of Vyper

™

drive coolant. With

this information, the Quantum

™

LX delivers a 4-20 mA signal

to the 3-way mixing valve, based on the setpoints of a PID

loop output from the Quantum

™

LX. This signal will maintain

the Vyper

™

coolant temperature at the control setpoint for

the PID loop. This setpoint will be set at 110°F at the factory.

There are also low and high temp alarms and shutdowns as-

sociated with the Vyper

™

coolant temperature reading. These

wil also be factory set for a Low Temp. alarm and shutdown

at 85°F and 80°F with a 90 second delay, when running.

The High Temp. Alarm and shutdown will be factory set at

125°F and 130°F with a 30 second delay when running. If

the Vyper

™

coolant temperature drops too low, condensation

may occur, damaging vital electronic components.In addi-

tion to controlling the Vyper

™

cabinet cooling system, the

Quantum

™

LX panel also monitors four temperatures from

the Vyper

™

cabinet. If any of these temperatures rise too

high, the Quantum

™

LX panel will go to a Stop Load condi-

tion, preventing either the slide valve position or motor speed

from increasing. If the temperature continues to rise, the

Quantum

™

LX panel will next go to a Force Unload condition.

In this situation, the slide valve will unload to lower the motor

torque required, in an effort to drop the temperature in the

panel. Below is a chart showing the Stop Load and Force

Unload temperatures as well as the temperatures where the

Vyper

™

cabinet will automatically shut down.

location

Stop Start Force Unload Shutdown

Base plate

Temp Converter

160°F

165°F

175°F

Heat Sink Temp

155°F

160°F

170°F

Harmonic Filter

130°F

135°F

145°F

Base plate Temp

160°F

165°F

175°F

VYPER

™

CONFIGURATIONS - liquid Cooled

HP

Freq

A

B

C

D

E

F

G

H

J

K

l

M

N

254

50

51

42.5

4.25

47

51

5.5

17

36

70

22.5

20.4

16.4

2

305

60

51

42.5

4.25

47

51

5.5

17

36

70

22.5

20.4

16.4

2

362

50

58

49.5

4.25

54

58

5.5

19.1

41

75

24.6

22.5

18.5

2

437

60

58

49.5

4.25

54

58

5.5

19.1

41

75

24.6

22.5

18.5

2

Remote-mounted configuration is shown. Pack-

age-mount dimensions are identical except for

the elimination of the stand. Coolant connections

to the Heat Exchanger are 1½ NPT.

NOTE: Considering all applicable codes regarding

spacing and clearance, be sure to provide adequate

space behind the drive for servicing the cooling

circuit (recommended 18” minimum).

Содержание Vyper 254

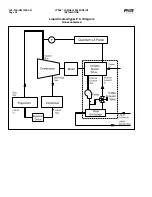

Страница 17: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 17 Liquid Cooled Vyper P I Diagram Economized...

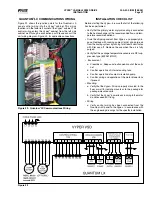

Страница 26: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 26 ANALOG BOARD WIRING Figure 21...

Страница 67: ...100 200 IOM FEB 09 Page 67 VYPER VARIABLE SPEED DRIVE NOTES...