VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 11

Recommended Analog signal wire

0.750 mm2 (18AWG) twisted pair, 100% shield with drain.

If the wires are short and contained within a cabinet which

has no sensitive circuits, the use of shielded wire may not

be necessary, but is always recommended.

Recommended Digital signal wire

Unshielded Per US NEC or applicable electrical code.

Shielded

0.750 mm2 (18AWG), 3 conductor, shielded.

TRANSFORMERS

In most installations the transformer that supplies the refrig-

eration equipment is the same transformer that powers most

of the other loads in the same building. These transformers

are generally very large relative to the refrigeration load.

However is some case there will be an individual transformer,

sized and dedicated to the refrigeration system alone. For

example, when a 460 VAC VSD is used and the existing

power is 208V, a 208 V to 460V step-up transformer should

be installed.

Such transformers must be specially sized whenever a

Vyper

™

is involved. Failure to properly size the transformer

may result in unreliable operation.

NOTE: Contact the fac-

tory or power provider for transformer sizing.

NOTE: Transformer must be K4 rated.

When installing a Vyper

™

on an existing transformer, the

total KVA requirement of the VSD controlled system and all

branch circuits must be considered. The transformer sup-

plying the Vyper

™

shall be sized such that the transformer

voltage does not sag more than 5% when subjected to load

excursions. The steady-state operating voltage should be

within the range of 414 to 508 VAC, 3 phase 60 Hz, or 342-

423 VAC, 3 phase, 50 Hz.

KVA

Impedance

Weight (lb)

175

5%-6%

1100

220

5%-6%

1470

275

5%-6%

1750

330

5%-6%

1990

440

5.5% - 6.5%

2700

550

5.5% - 6.5%

3100

660

5.5% - 6.5%

3600

750

6% - 7%

4600

880

6% - 7%

5300

990

6% - 7%

5800

1250

6.5% - 7.5%

6200

1500

6.5% - 7.5%

6800

1750

6.5% - 7.5%

7500

2000

6.5% - 7.5%

8200

Johnson Controls offers a line of Recommended Vyper

VSD Transformers. These transformers have the following

features:

• Steel core for low flux density operation.

• Standard K-4 rating. K-13, K-20, K-30 is available as an

option.

• UL / CSA certified.

• 600 Volt class

•

Primary Voltage: 208V, 230V, 460V, 575V

• Conductors, 40°C ambient

•

Sinusoidal loading not to exceed K-4

•

Secondary Voltage: 460

• NEMA 2 housing

• 60 Hz, 150°C temperature rise, 220°C insulation

• Taps: 1 plus, 1 minus@5%

POWER FACTOR CAPACITORS

Power factor correction capacitors are not required since the

Vyper

™

has a 0.95 minimum power factor at all operational

loads and conditions. Capacitors can be located at one or

several places on a distribution system. Solid-state motor

controllers may not run, or have difficulty starting in that

scenario. The degree of malfunction depends on the size of

the capacitors, the distance away for the solid-state controls,

and the size of the building supply transformer.

With a VSD there is no way to know in advance whether the

capacitors will cause interference. When a VSD is started and

there are problems cause by power factor capacitors, it will be

necessary to remove those capacitors. In some installations,

capacitors are switched on line as power factor drops.

The switching transients created by connecting and discon-

necting power factor capacitors may cause the Vyper

™

to drop

off-line. High voltage power factor capacitors may be located

on the primary side of the transformer supplying power to

the Vyper

™

without causing any malfunction to equipment

on the secondary side.

SOFT-START SEQUENCE

At start-up, both the motor and slide valve begin to load to

a preset value.

NOTE: There is a 30 second delay at initial start-up to

charge the capacitors of the Vyper

™

. This delay does not

occur in Standby mode, only on initial start-up.

The Frick slide valve will load to the Variable Speed Minimum

Slide Valve Position setpoint, and the Vyper accelerates to the

speed corresponding to the Minimum Drive Output setpoint.

From this point the slide valve position and motor speed are

controlled by the Capacity Control setpoints.

During start-up, the VSD varies the voltage and frequency

to maintain the same proportion that exists between the two

at design conditions. The required inrush current to start the

motor never exceeds the FLA rating of the given motor and is

typically only 10-20% of FLA. Mechanical forces on the motor

windings and motor heating are 20% to 50% lower than with

a mechanical starter. This results in less mechanical shock

to the system and longer motor life.

INTERFACING ElECTRICAl EQUIPMENT

There are many low voltage DC signals in the Vyper

™

which

may be picked up from other electrical devices or wiring in the

vicinity of the electronic controls. It is essential that non-VSD

wiring is not routed through the Vyper

™

cabinet. It is equally

important that no external equipment is tied to the Vyper

™

control wiring in any way. A control system should never be

wired to the Vyper

™

circuitry. Never use 120V supply to feed

the VSD control wiring. The Vyper

™

has it’s own internal

power supply. Using an external supply may damage the

Vyper

™

and may also cause hazardous working conditions

for service and operating personnel.

Содержание Vyper 254

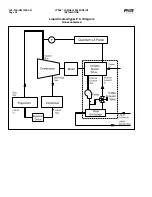

Страница 17: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 17 Liquid Cooled Vyper P I Diagram Economized...

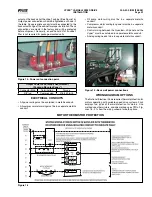

Страница 26: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 26 ANALOG BOARD WIRING Figure 21...

Страница 67: ...100 200 IOM FEB 09 Page 67 VYPER VARIABLE SPEED DRIVE NOTES...