RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-200 IOM

Page 9

HOT ALIGNMENT OF COMPRESSOR/MOTOR

Hot alignments can only be made after the unit has op er at ed

for several hours and all components are at operating tem-

peratures.

Shut down the unit and quickly affi x dial indicator to cou pling

mo tor hub, then take readings of both the face and rim of the

compressor hub. If these readings are within tol er ance, record

reading, attach coupling guard and restart unit. How ev er, if

the reading is not within lim its, compare the hot read ing with

the cold alignment and adjust for this dif fer ence; i.e. if the

rim at 0° and 180° readings indicates that the motor rises

.005" between its hot and cold state, .005" of shims should

be re moved from under the motor.

After the initial hot alignment adjustment is made, restart unit

and bring to operating temperature. Shut down and re check

hot alignment. Repeat pro ce dure unit hot align ment is within

spec i fi ed tolerance.

I N S TA L L C O U

P L I N G G UA R D

B E F O R E O P E R AT I N G C O M -

PRES SOR.

OIL PUMP COUPLING

Compressor units with direct motor/pump cou pled pumps

need no pump/motor coupling alignment since this is main-

tained by the close-coupled arrangement.

HOLDING CHARGE AND STORAGE

Each RWB II compressor unit is pressure and leak tested at

the Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

en sure that the nitrogen charge is safely released.

Holding charge shipping gauges

on separator and ex ter nal oil cool er

are rated for 30 PSIG and are for

check ing the ship ping charge only. They must be re-

moved before pressure testing the sys tem and before

charg ing the sys tem with re frig er ant. Failure to remove

these gaug es may result in cat a stroph ic fail ure of the

gauge and un con trolled re lease of re frig er ant re sult ing

in se ri ous in ju ry or death.

All units must be kept in a clean, dry location to prevent

cor ro sion dam age. Reasonable con sid er ation must be

giv en to proper care for the solid-state com po nents of the

mi cro pro ces sor.

Unit which will be stored for more than two months must have

the nitrogen charge checked periodically.

COMPRESSOR UNIT OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mix ing of oils may cause ex ces sive

oil foam ing, nuisance oil level cut outs, oil pressure

loss, gas or oil leakage and cat a stroph ic compressor

failure.

Use only Frick

®

refrigeration oil

and fi lters or warranty claims may

be denied.

The oil charge shipped with the unit is the best suited lu-

bri cant for the con di tions specifi ed at the time of pur chase.

If there is any doubt due to the refrigerant, operating pres-

sures, or temperatures, refer to Frick Pub. E160-802 SPC

for guid ance.

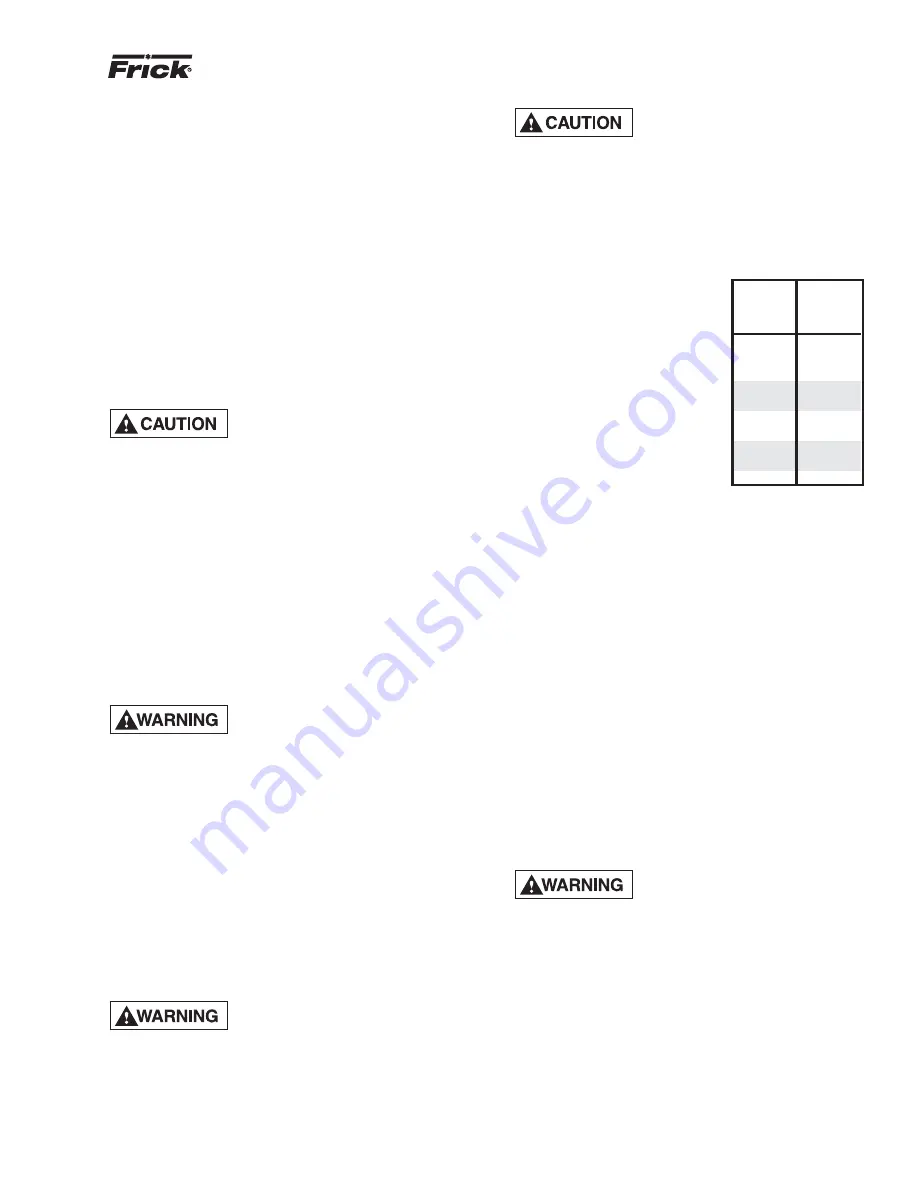

OIL CHARGE

The normal charging level is mid-

way in the top sight glass located

mid way along the oil sep a ra tor

shell. Normal op er at ing lev el is

mid way be tween the top sight

glass and bot tom sight glass.

The table gives the ap prox i mate oil

charge quan ti ty.

* Includes total in oil sep a ra tor and

pip ing. Additional oil supplied for

oil cool er.

Add oil by at tach ing the end of a

suitable-pressure-type hose to the

oil charging valve, lo cat ed on the

top of the oil sep a ra tor at the com pres sor end. Using a

pres sure-type pump and the rec om mend ed Frick oil, open

the charg ing valve and pump oil into the sep a ra tor. NOTE:

Fill slow ly be cause oil will fi ll up in the sep a ra tor faster

than it shows in the sight glass.

Oil distillers and similar equipment which act to trap oil must

be fi lled pri or to unit operation to nor mal design outlet lev els.

The same pump used to charge the unit may be used for

fi lling these auxiliary oil res er voirs.

NOTE: The sight glass located in the coalescing end

of the sep a ra tor near the discharge con nec tion should

re main empty.

OIL HEATER(S)

Standard units are equipped with two or three 500 watt oil

heat ers, providing suffi cient heat to maintain the oil tem-

per a ture for most indoor ap pli ca tions during shut down cy cles

to per mit safe start-up. Should ad di tion al heating capacity

be re quired be cause of low am bi ent tem per a ture, con tact

Frick. The heat ers are en er gized only when the unit is not

in op er a tion.

DO NOT ENERGIZE THE HEAT ERS

when there is no oil in the unit, the

heat ers will burn out. The oil heat-

ers will be en er gized when ev er 120 volt con trol pow er is

ap plied to the unit and the com pressor is not run ning,

un less the 16 amp circuit break er in the micro en clo sure

is turned off.

60

35

76

35

100

65

134

65

177

110

222

110

270

140

316

140

399

140

480

170

BASIC*

CHARGE

(gal.)

RWB II

MODEL

NO.

Содержание RWB II

Страница 43: ...RWB II ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 200 IOM Page 43 P I DIAGRAM...

Страница 46: ...RWB II ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 200 IOM Page 46 P I DIAGRAM LIQUID INJECTION BOOSTER...

Страница 50: ...RWB II PLUS ROTARY SCREW COMPRESSOR UNITS FORMS S70 200 IOM Page 50 OPERATING LOG SHEET...