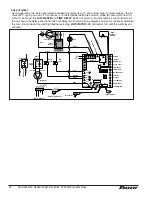

Electrical control system operation

The P425A/W, MCD425A/W_S and R425A/W wiring diagrams which follow illustrate the circuitry of Follett ice

machines used with ice dispensers . Both normal operation of the ice machine (Stages 1–6) and non-normal

diagnostic sequences showing torque-out (Stages 7–10) for use in troubleshooting ice machine problems are

shown .

Circuitry notes

When the ice machine is used with a dispenser it receives power from the main power supply . Disconnect the

power source before performing service . When performing electrical service, always use a meter to determine

whether or not the components being serviced are energized .

§

High pressure cutout opens at 425 PSI and closes at 287 PSI (auto reset) .

§

The bin signal input to the control board in the 425A/W ice machine must only be initiated by contact closure . Do

not supply power . To run the ice machine in the workshop, use the bin signal jumper (P/N 01069095)

.

Note: The operation stage descriptions that follow are based on the unit containing the split-phase gear

motor.

Normal operation – Stage 1

Power is supplied to L1 of the control board, the

POWER LED light begins flashing . The ice level bin thermostat in

the dispenser is closed and calling for ice, supplying contact closure to the control board . The

LOW BIN LED will

be on . The control board will now go through the start-up sequence . The board checks the water sensors (located

in the reservoir) for continuity between the common probe (B) and the high probe (C) . If continuity is not sensed,

the water fill valve (P21) is energized .

5

2

1

Start

Run

Compressor

T.O.L.

MAINTENANCE

LOW WATER

TIME DELAY

SLEEP CYCLE

MAKING ICE

LOW BIN

POWER

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

High

Pressure

Switch

R S

C

Gearmotor

Start

Relay

Start

Relay

N

L1

Fan

A B C D

Water Sensors

RESET

Fill

Valve

Drain

Valve

3

4

2

Bin T-Stat

Clean Switch

Drain Clog Sensor

P6

P21

P20

P19

P3

P22

P4

AUGER

WATER LEVELS

BIN P11

HI PRS

L1

R

S

C

RED

WHITE

WHITE

BLACK

BROWN

BLUE

RED

BLACK

YELLOW

Compressor

Electrical Box

COMPRESSOR

1 2 3 4 5 6 7 8

BLACK

N

P15

Ice Dispense Input

Capacitor

BLACK

YELLOW

OR

NO CONNECT

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 15