14

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

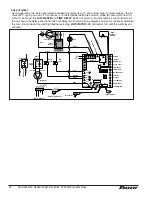

Electrical control system schematic

WATER LEVELS

P17

BIN

P12

CLEAN SAFE

P11

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

CLEANER FULL

RESERVOIR

WATER SENSOR

MAINT.

CLEAN

HI PRS

P14

HIGH

PRESS

P

A B C D

BLACK

YELLOW

ORANGE

RED

GRN #17

BLACK #51

BLACK #23

BIN

CONTACT

CLOSURE

L1

L2/N

DISP

GND

BLACK #23

GRN-YEL #24

WHITE #25

BLACK #26

WHITE

BLUE

SPLIT-PHASE

START

RELAY

3

4

2

YELLOW

BLACK

T.O.L.

START

RUN

FAN

FEED VALVE

DRAIN VALVE

RED #16

WHITE #121

WHITE #13

BRO

WN #14

BLA

CK #122

BL

UE #07

BLA

CK #51

WHITE #52

COMP.

R

C

S

O.L.

C2 START

1 2 3 4 5 6 7 8 9

GREEN #53

COMPRESSOR

COMPRESSOR

ELECTRICAL

BOX

BLA

CK #51

WHITE #52

GREEN #53

RED #54

ORANGE #55

BLA

CK #56

GREEN #57

BLACK #58

BLACK #59

6

4

1

2

5

BLA

CK #61

WHITE #62

GREEN #63

WHITE #64

BLA

CK #65

BLA

CK #66

GREEN #67

BLA

CK #68

BLA

CK #69

C1 RUN

BLACK #66

BLACK #69

BLACK #71

#15

#04

#05

WHITE

DRAIN CLOG

SENSOR

BLACK

VIOLET

DRAIN CLOG

MODEL SELECT

SERIAL COMM

COMPRESSOR

AUGER

WATER LEVELS

HI PRS

BIN

RS485

RS485 UI

CURRENT SENS

RESET

PROGRAM

P5

ICE AUX

WATER AUX

D9

D8

D7

D6

D5

D4

D37

D3

D2

D18

D16

D15

D14

D13

D12

D11

D10

D1

T1

P18

P11

P13

P17

P12

P14

P16

P15

P4

T2

S1

S2

K1

P7

P8

P10

K3

1

2

6

5

P9

L1

L1

L1

N

N

N

N

N

N

N

N

N

P2

P1

P21

P20

P19

P3

BLACK #01

P6

P22

D19

D22

D21

D20

D17

D48

BLA

CK

BLA

CK

BLUE

OR

CAPACITOR

T.O.L.

START

RUN

BLACK

YELLOW

PSC MOTOR

Water-Cooled ice machine capacity/24hrs.

Condenser Water Temperature F/C

Inlet

W

at

er T

emper

atur

e

F/C

F

50

60

70

80

90

100

C

10

16

21

27

32

38

50

486

465

443

422 400 389 lbs .

10

220

211

201

191 181 176

kg .

60

464

445

425

406 386 367 lbs .

16

210

202

193

184 175 166

kg .

70

443

425

408

390 372 358 lbs .

21

201

193

185

177 169 162

kg .

80

422

406

389

373 356 340 lbs .

27

191

184

176

169 161 154

kg .

90

400

385

371

356 341 326 lbs .

32

181

175

168

161 155 148

kg .

Air-Cooled ice machine capacity/24hrs.

Ambient Air Temperature F/C

Inlet

W

at

er T

emper

atur

e

F/C

F

60

70

80

90

100

C

16

21

27

32

38

50

460

425

390

355

320

lbs .

10

208

193

177

161

145

kg .

60

437 .5

405

372 .5

340

307 .5 lbs .

16

198

184

169

154

139

kg .

70

415

385

355

325

295

lbs .

21

188

175

161

147

134

kg .

80

405

375

345

315

285

lbs .

27

184

170

156

142

129

kg .

90

395

365

335

305

275

lbs .

32

179

166

152

138

125

kg .

Note: Nominal values - actual production may vary by ±10% .