Operating Manual EMGZ309._.EIP

13

4.8

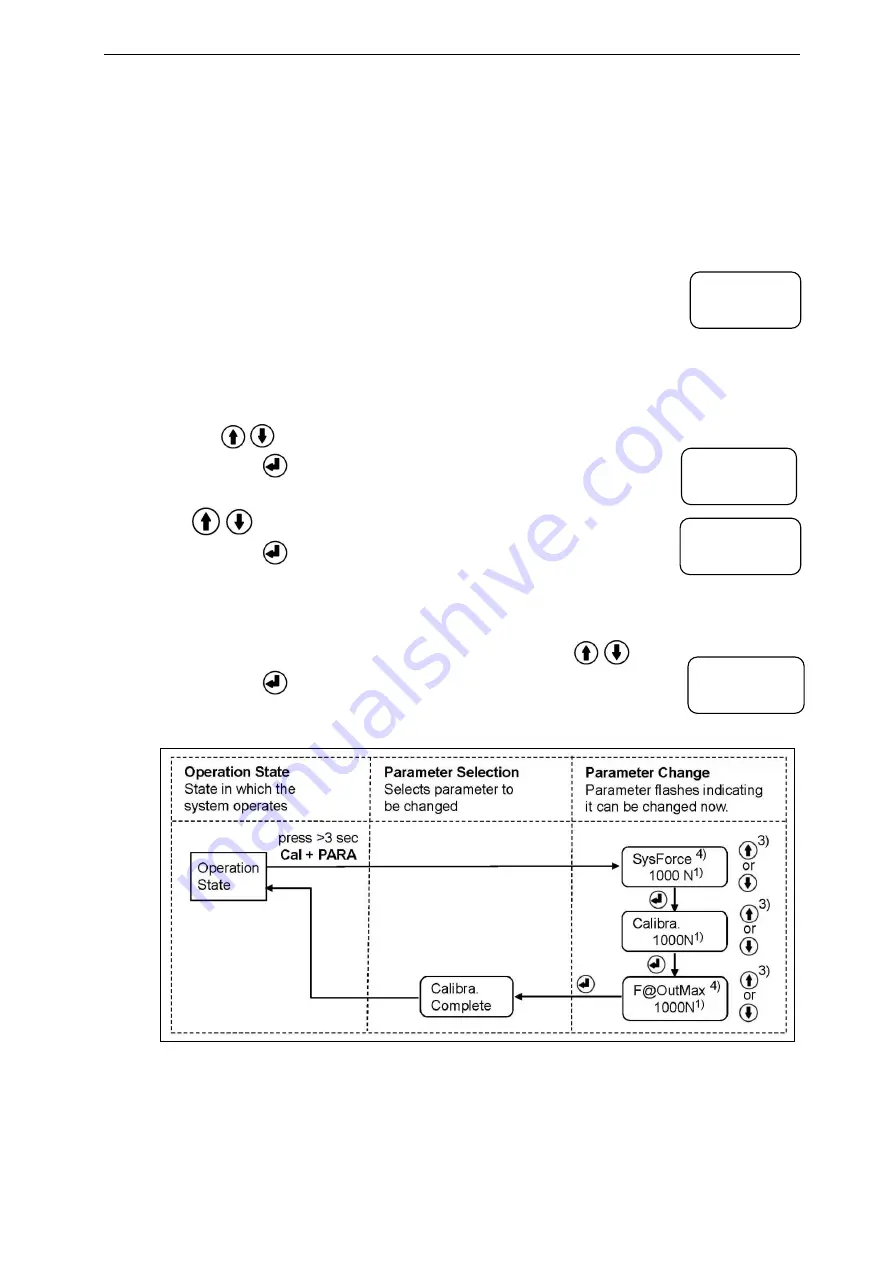

Calibration over the Operating Panel

1.

Load a rope with a defined weight corresponding to your calibration force on the

roller. The roller configuration must correspond to the real configuration in the

machine (wrap angle, distance of the rollers etc.).

2.

The calibration mode can be entered by pressing the two keys Cal and PARA at

the same time for longer than 3 seconds. Display changes to

The System Force [SysForce] determines the measuring

capability of your measuring roller. E.g. if two 500 N sensors are

installed in the measuring roller, enter 1000N. If only one 500N sensor is used,

enter 500N (see 8.3 “Descriptions of Parameter”, [SysForce]).

3.

The parameter [SysForce] flashes indicating that the force can now be changed.

Use

keys to enter the system force.

4.

Press the

key to confirm your input. Display will change to

5.

Enter the force corresponding to your calibration weight with the

keys.

6.

Press the

key to confirm your input. Display will change to

7.

With the parameter [F@OutMax] the force corresponding to the maximum

amplifier output (10V or 20mA) can be assigned (see 6.3 “Descriptions of

Parameter”, [F@MaxOut]). Enter the value with the

keys.

8.

Press the

key to confirm your input. Display will change to

The calibration procedure has been completed successfully.

Fig. 8: State diagram calibration

E

MGZ309015e

1)

The display shows the unit of measure that was previously selected.

3)

Permanent key pressing expedites the changing speed.

4)

If the Device Mode [VoltGauge] is set, these parameters are deactivated

SysForce

1000.0 N

Calibra.

1000.0 N

F@OutMax

1000.0 N

Calibra.

Complete