Logix

®

420 Digital Positioner FCD LGENIM0106-07-AQ – 10/15

10

Table 10: FlowTop and GS Take-Off Plate and Pin Configurations

Actuator

Stroke

(mm)

Plate and Pin

Orientation

127 / 252

10

127 / 252

20

502

20 or 40

5.2 Mounting to NAMUR Valves

1. Attach the mounting plate to the positioner using 4 screws.

2. Rotate the feedback shaft to match the orientation of the receiver on

the actuator.

NOTE:

The feedback shaft has a clutch mechanism that allows for

over-rotation of the shaft for easy adjustments.

3. Mount the positioner onto the actuator using the washers and nuts.

4. Connect regulated air supply to appropriate port in manifold. See

section 6 TUBING.

5. Connect the power to the 4-20 mA terminals. See section 7

ELECTRICAL CONNECTIONS.

6. Remove main cover and locate DIP switches and QUICK-CAL/

ACCEPT button.

7. Refer to sticker on main board cover and set DIP switches accord-

ingly. See section 8 STARTUP

8. Press the

►

QUICK-CAL/ACCEPT button for three to four seconds

or until the positioner begins to move. The positioner will now

perform a stroke calibration.

9. If the calibration was successful the green LED will blink GGGG or

GGGY and the valve will be in control mode.

10. If calibration fails, as indicated by a RGGY blink code, retry the

calibration. If it still fails, remove power from the positioner, discon-

nect the air, and remove the positioner from the actuator. Rotate the

feedback shaft so that the full free travel of the feedback shaft is in

the range of the actuator movement. Optionally, continue to attempt

the calibration. Each calibration attempt adjusts the acceptable

limits and it should pass eventually.

1

CAUTION: Remember to remove the air supply before

re-adjusting take-off arm.

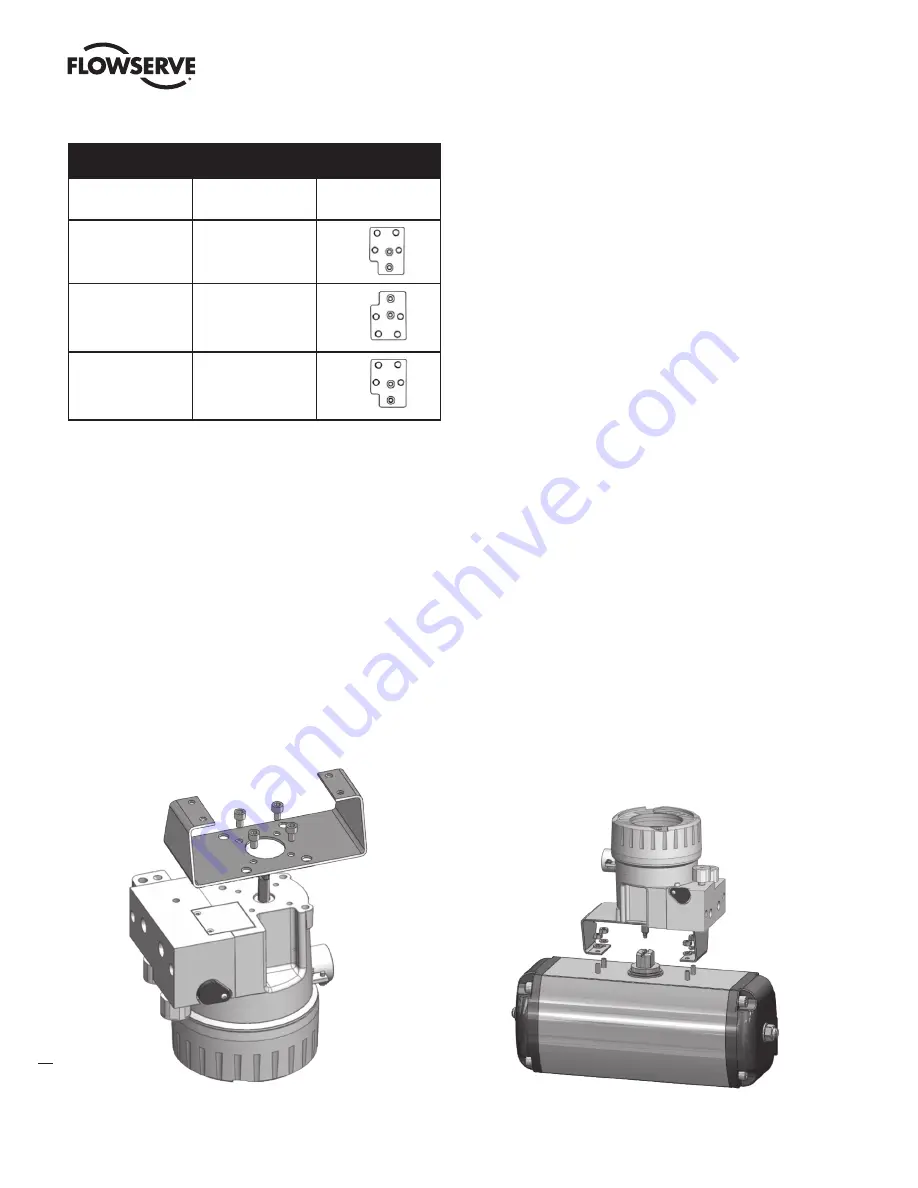

Figure 3: NAMUR Bracket

Figure 4: AutoMax Assembly