QS204215 Rev B

9

|

IMPORTANT MOUNTING GUIDELINES

1. Never mount the sensor at an angle.

2. Liquid should never enter the dead band.

3. Mount sensor at least 3” from the side wall.

4. Never mount the sensor in a vacuum.

5. Do not obstruct the sensor’s beam width.

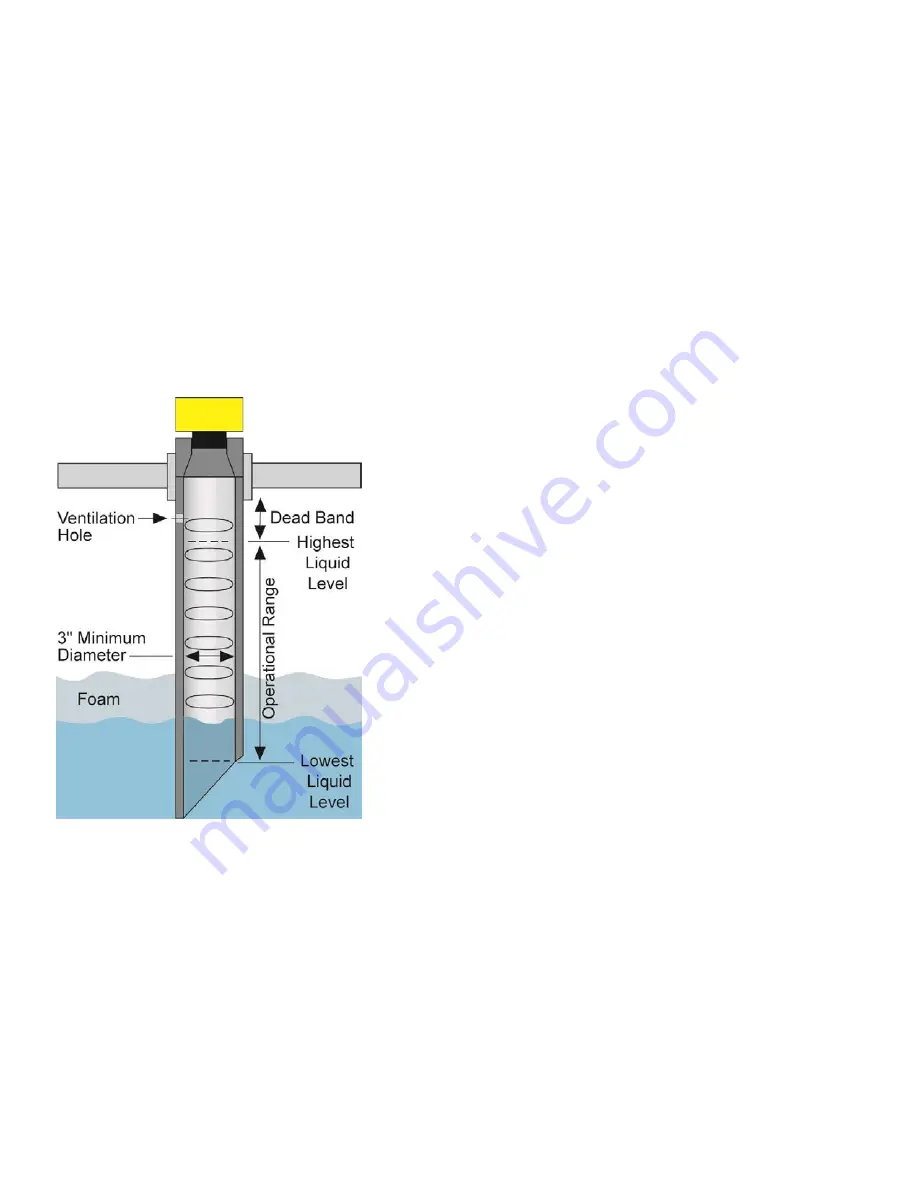

MOUNTING IN STAND-PIPE

A stand-pipe may be used to dampen turbulence, separate surface foam from the point of measurement or

increase performance in heavy vapor. When mounting the sensor in a stand-pipe, the minimum diameter of

the pipe is 3”. Larger diameter pipes can be used. The pipe should be attached with a coupling and reducer

bushing. The pipe length should run the measurement span and the bottom of the pipe should remain

submerged at all times to prevent foam from entering the pipe. Cut the bottom end of the pipe at 45° and drill

a 1/4”pressure equalization hole high in the sensor’s dead band. Locate the stand-pipe away from pump

outlets and/or other sources of substantial turbulence which might cause the liquid in the pipe to oscillate.