FIREPOWER 160S

OPERATION

Operation

4-4

Manual 0-5369

4.05 GTAW Electrode Polarity

Connect the TIG torch to the "-" Negative Output Terminal and the work lead to the "+" Positive Output Terminal for

direct current straight polarity. Direct current straight polarity is the most widely used polarity for DC TIG welding. It

allows limited wear of the electrode since 70% of the heat is concentrated at the work piece.

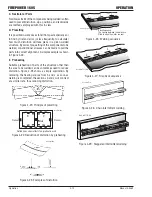

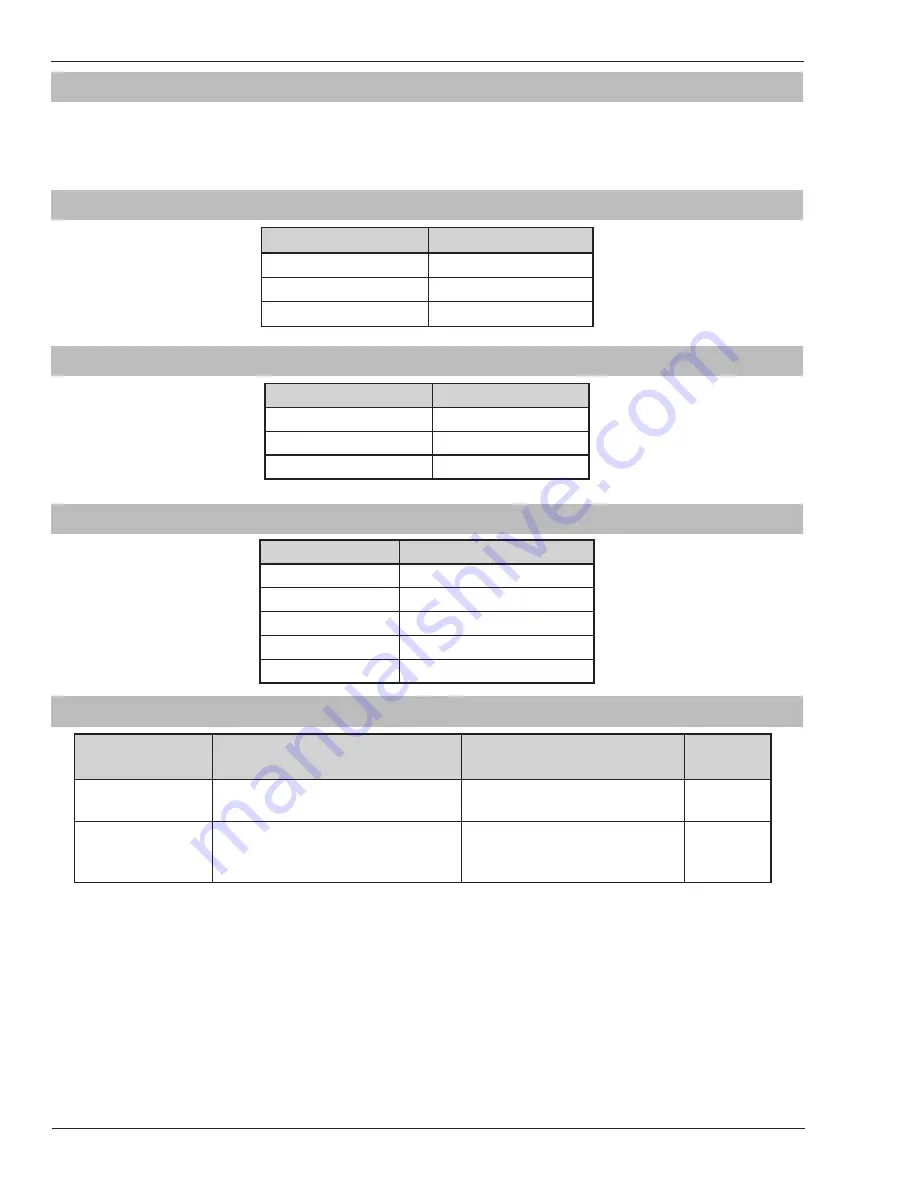

4.06 Guide for Selecting Filler Wire

Filler Wire Diameter

DC Current (Amps)

1/16" (1.6mm)

20 - 90

3/32" (2.4mm)

65 - 115

1/8" (3.2mm)

100 - 165

4.07 Tungsten Electrode Current Ranges

Electrode Diameter

DC Current

.040” (1.0mm)

25 - 85

1/16” (1.6mm)

50 - 160

3/32” (2.4mm)

135 - 235

4.08 Shielding Gas Selection

Alloy

Shielding Gas

Carbon Steel

Welding Argon

Stainless Steel

Welding Argon

Nickel Alloy

Welding Argon

Copper

Welding Argon

Titanium

Welding Argon

4.09 Tungsten Electrode Types

Electrode Type

(Ground Finish)

Welding Application

Features

Color Code

Thoriated 2%

DC welding of mild steel, stainless steel

and copper.

Excellent arc starting, long life, high

current carrying capacity.

Red

Ceriated 2%

AC & DC welding of mild steel, stainless

steel, copper, aluminum, magnesium and

their alloys.

Longer life, more stable arc, easier

starting, wider current range,

narrower & more concentrated arc.

Grey