SAFETY INSTRUCTIONS

FIREPOWER 160S

Manual 0-5369

1-5

Safety Instructions

The following is a quotation from the General Conclusions

Section of the U.S. Congress, Office of Technology As-

sessment, Biological Effects of Power Frequency Electric

& Magnetic Fields - Background Paper, OTA-BP-E-63

(Washington, DC: U.S. Government Printing Office, May

1989): “...there is now a very large volume of scientific

findings based on experiments at the cellular level and

from studies with animals and people which clearly estab-

lish that low frequency magnetic fields interact with, and

produce changes in, biological systems. While most of

this work is of very high quality, the results are complex.

Current scientific understanding does not yet allow us to

interpret the evidence in a single coherent framework.

Even more frustrating, it does not yet allow us to draw

definite conclusions about questions of possible risk or to

offer clear science-based advice on strategies to minimize

or avoid potential risks.”

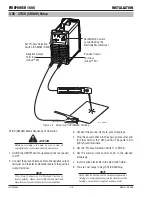

To reduce magnetic fields in the workplace, use the

following procedures.

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cable around the body.

4. Keep welding power source and cables as far away

from body as practical.

!

ABOUT PACEMAKERS:

The above procedures are among those

also normally recommended for pacemaker

wearers. Consult your doctor for complete

information.

1.02 General Safety Information for

Firepower CS Regulator

A. Fire Prevention

Welding and cutting operations use fire or combustion

as a basic tool. The process is very useful when properly

controlled. However, it can be extremely destructive if not

performed cor rectly in the proper environment.

1. The work area must have a fireproof floor.

2. Work benches or tables used during welding or cutting

operations must have fireproof tops.

3. Use heat resistant shields or other approved material to

protect nearby walls or unprotected flooring from sparks

and hot metal.

4. Keep an approved fire extinguisher of the proper size

and type in the work area. Inspect it regularly to ensure

that it is in proper working order. Know how to use

the fire extin guisher.

5. Move combustible materials away from the work site.

If you can not move them, protect them with fireproof

covers.

!

WARNING

NEVER

perform welding, heating, or cutting

operations on a container that has held toxic,

combustible or flammable liq uids, or vapors.

NEVER

perform welding, heating, or cutting

operations in an area containing combustible

vapors, flam mable liquids, or explosive dust.

B. Housekeeping

!

WARNING

NEVER

allow oxygen to contact grease, oil, or

other flam mable substances. Although oxy-

gen by itself will not burn, these substances

become highly explosive. They can ignite and

burn violently in the presence of oxygen.

Keep ALL apparatus clean and free of grease, oil and other

flammable substances.

C. Ventilation

!

WARNING

Ade quately ventilate welding, heating, and

cutting work areas to prevent accumulation

of explosive or toxic concen trations of gases.

Certain combinations of metals, coatings, and

gases generate toxic fumes. Use respiratory

protection equipment in these circumstances.

When welding/brazing, read and understand

the Material Safety Data Sheet for the welding/

brazing alloy.

D. Personal Protection

Gas flames produce infrared radiation which may have

a harm ful effect on the skin and especially on the eyes.

Select goggles or a mask with tempered lenses, shaded

4 or darker, to protect your eyes from injury and provide

good visibility of the work.

Always wear protective gloves and flame-resistant clothing

to protect skin and clothing from sparks and slag. Keep col-

lars, sleeves, and pockets buttoned.

DO NOT

roll up sleeves

or cuff pants.

When working in a non-welding or cutting environment,

always wear suitable eye protection or face shield.