start from a higher wire speed. This operation prevents damage to the contact tip during

welding. During welding, keep the torch at a 45º angle from the workpiece.

SELECTING WIRE

WIRE DIAMETER SELECTION

Using a wire that is too small in diameter causes excessive weld spatter and weld heat. Wire that is too large

causes wire stubbing. Stubbing occurs when the molten metal bridge between the electrode and weld pool can-

not be broken and the electrode stubs into the pool and the pool freezes. Wire that is too large at low amper-

ages can cause an uneven arc. In either case the weld is ruined. Use Table 2 below to identify the recommend-

ed wire diameter to use for the metal being welded. These recommendations are for typical applications only.

WIRE SPOOL SIZE SELECTION

This welder accepts a 2-lb. spool. Welding wire oxidizes over time.

1.

STEEL WIRE

- is usually coated with copper to prevent rusting and to strengthen the transmission of the

welding current from the contact tip to the wire. We recommend that copper-coated steel welding wire be

purchased in spool sizes that will be used in 6 months are less. The copper coating begins oxidizing in the

early stages of aging. As time passes, the oxidation gets heavier. Check the wire for copper oxidation by

unspooling about 2 feet of wire. Pinch the wire between the thumb and forefinger. Pull the thumb and fore-

finger down the length of the wire. Look at the line created by the copper oxidation on the thumb and fore-

finger. A fresh spool leaves a light gray line. A well-oxidized spool leaves a darker line. Heavy copper oxi-

dation causes arc flutter and possibly wire drive slippage. If steel wire continues to oxidize, the steel wire

under the copper coating will rust and cause even worse arc flutter and drive problems.

2.

SELF-SHIELDING, FLUX-CORE, STEEL WIRE

- spools should be selected based on the same guide-

lines as for copper-coated steel wire.

3.

ALUMINUM WIRE

- has a greater storage problem than steel. It oxidizes much faster and the oxidation is

much heavier. The early stages of oxidation are virtually invisible. As time passes, a white powder develops

that causes extreme arc flutter, wire drive problems, contamination build-up in the liner, wire burn-back into

the contact tip and a poor weld. Use up a spool of aluminum wire within three months.

4.

STAINLESS STEEL WIRE

- oxidizes a slow rate. Its oxidation is light. Handling and storing stainless

steel wire is less critical than for aluminum and steel wires.

5.

SILICON-BRONZE WIRE

- spools use the same guidelines as for copper-coated steel wire.

The above recommended spool storage times are rules-of-thumb. Storage times are impacted by the time in

distribution prior to retail sale, warehouse conditions, time of year and packaging.

Although these factors are out of your control, you can slow down the oxidation process by the following:

Store the wire in a dry place when not in use;

Store the wire in sealed plastic bag;

Leave unopened in the manufacturer's package until ready to use.

If a spool of wire looks heavily oxidized, unspool a few turns of wire. Determine if

the wire further down the spool is usable. If a spool has developed heavy oxidation, discard

the spool of wire.

11

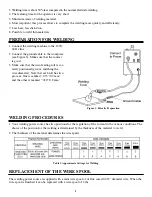

Table 2: Wire Diameter Amperage Ranges (Typical)

Содержание FP-90

Страница 2: ......

Страница 27: ...23 Figure 21 FP 90...

Страница 29: ...25 Figure 22 FP 90 Wiring Diagram...

Страница 30: ...26...