6

Commissioning

6.1 Preparing for commissioning

Note

Make sure that the following conditions

are observed:

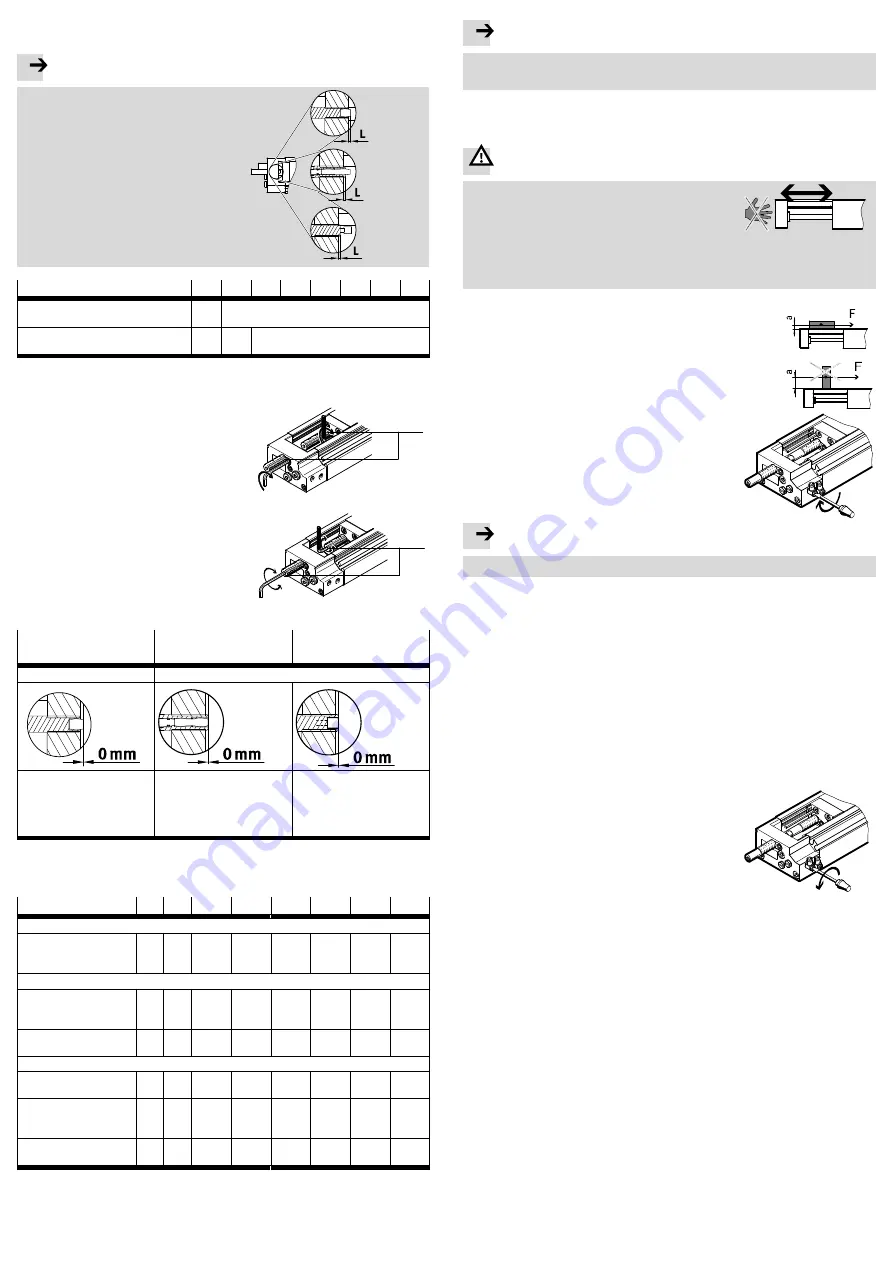

– The distance L of the cushioning com

ponent must be maintained at a min

imum (factory setting)

(

è

Falling below the factory settings

destroys the guide.

– For all setting work, all threads of the

cushioning component are constantly

being manipulated.

Fig. 16

DGSL-…-E

DGSL-…-P

DGSL-…-P1

DGSL-…-Y3

DGSL-…-Y11

DGSL

4

6

8

10

12

16

20

25

Distance L with

DGSL-…-E/-P/-P1

[mm]

1

1.5

Distance L with

DGSL-…-Y3/-Y11

[mm]

–

–

1.5

Fig. 17

For precision adjustment of the end positions:

1. Loosen clamping component

aE

.

2. Position the slide by hand in the desired

end position.

Fig. 18

aE

3. Turn the cushioning component

1

with a

hexagon wrench until the end position is

reached (

è

The max. torque must be observed thereby

(

è

4. Retighten the clamping component with

the following tightening torque (

è

Fig. 19

1

DGSL-…-E,DGSL-…-P

with rubber buffer

DGSL-…-P1 with rubber

buffer and stop sleeve

DGSL-…-Y3

,

DGSL-…-Y11

with shock absorber

1)

No metallic stop

Metallic stop

The rubber buffer touches the

slide.

The stop sleeve touches the

slide (against the force of the

cushioning)

The shock absorber housing/

reducing sleeve

(for DGSL-…-Y11) touches the

slide (against the force of the

shock absorber)

1)

If the max. torque for the internal hexagon socket at the DGSL-…-Y3

is fallen below, the hexagon in the

shock absorber spins. The max. torque is summarised in the following table (

è

Fig. 20

DGSL

4

6

8

10

12

16

20

25

For all DGSL

Tightening torque

clamping

component

[Nm]

0.15

0.2

0.3

0.8

1.2

2.5

2.5

3.5

Only for DGSL-…-Y3

Max. torque

internal hexagon

socket

[Nm]

–

–

0.5

0.8

2.2

5

8

13

Shock absorber

type DYSW-…-Y1F

–

–

4-6

5-8

7-10

8-14

10-17

12-20

Only for DGSL-…-Y11

Max. torque

reducing sleeve

[Nm]

–

–

–

0.8

2.2

5

8

13

Max. torque

internal hexagon

socket

[Nm]

–

–

–

0.5

0.8

2.2

5

8

Shock absorber

type DYSW-…-Y1F

–

–

–

4-6

5-8

7-10

8-14

10-17

Fig. 21

Note

The exact slide position must be checked during a test run with compressed air

applied and, if necessary, corrected.

6.2 Carrying out commissioning

Before each commissioning and in operation:

Warning

Make sure that in the travel range of the drive

– Nobody can reach into the path of the movable

components (e.g. by providing a protective

guard).

– There are no foreign objects (e.g. hexagon

wrench when setting the end position under pres

sure).

Fig. 22

Place your effective load on the slide of the

DGSL so that the break-down torque of the

dynamic force F and the lever arm a remains

small.

Fig. 23

Turn both upstream one-way flow control valves

– at first completely closed

– then one rotation open again

Fig. 24

Note

Make sure that the operating conditions lie within the permissible ranges.

1. Pressurize the drive as follows:

– Pressurize the drive by

slowly

pressurizing one side.

For slow start-up pressurisation, use start-up valve type HEL.

The slide moves into an end position.

2. Start a test run with the moveable mass.

3. During the test run check whether the following points need to be modified:

– the speed and the acceleration of the moveable mass

– the end position

– the mass of the effective load

– the position of the proximity sensors.

If this is the case, the modifications must be carried out only when the slide is at

rest.

4. Open up the one-way flow control valves slowly

until the desired slide speed is reached.

The maximum permissible speed must

not

be

exceeded here (

è

12 Technical data).

The slide should reach the end position safely, but

not strike hard against it.

Too hard of an impact will cause the slide to re

bound out of the end position.

Fig. 25

If the slide can be heard to strike hard:

5. Interrupt the test run.

Causes of hard knocking may be:

– the moveable mass is too high

– the slide speed is too high

– no compressed air cushion on the exhaust side

– cushioning not sufficient (can be set for DGSL-…

-P1

).

6. Make sure you remedy the above-mentioned causes.

7. Repeat the test run.

When all necessary corrections have been undertaken:

8. End the test run.

9. Fasten the proximity switches in their final positions.