Festo — CMMT-ST-C8-1C-...-S0 — 2021-04b

Product overview

13

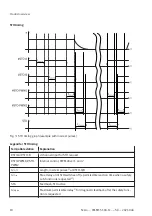

• If there are suspended loads and a motor with holding brake is used, they usually drop if STO is

requested immediately before the braking ramp has elapsed, because the engagement time of

the holding brake plays a significant role.

• The time t

3

must always be set to a value longer than the total of the braking ramp time t

1

and the

brake engagement time (t

2

– t

1

). This prevents the following:

• Suspended loads potentially dropping

• Increased wear on the holding brake

•

When selecting the delay time t

Delay

, make sure it is long enough to take account of the maximum

braking ramp time and brake engagement time.

4.1.4

Cross-wiring of several servo drives

Whether cross-wiring of the diagnostic contact is permissible depends on the safety classification

required.

The diagnostic contact must be evaluated separately for EC motors with the classification SIL 3, cat. 3,

PL e. It is not permissible to cross-wire the diagnostic contact. In all other cases, the following rules

apply when cross-wiring several servo drives:

–

Wire inputs #STO-A and #STO-B in parallel in each case.

–

Wire diagnostic contacts STA-C1/C2 in series in each case.

–

Wire the diagnostic contacts of a maximum of 10 servo drives in series. The maximum cable length

applies to the entire line, from the safety relay unit to the final device.

Example of cross-wiring

5.5 Connection Examples, Cross-wiring.

4.1.5

Fault exclusion

Put suitable measures in place to prevent faulty wiring:

–

Exclude wiring faults in accordance with EN 61800-5-2

–

Configure the safety relay unit to monitor the outputs of the safety relay unit and wiring up to the

servo drive

4.1.6

Safety relay unit

Use suitable safety relay units with the following characteristics:

–

2-channel outputs with

–

Detection of shorts across contacts

–

Required output current (also for STO)

–

Evaluation of the diagnostic contact of the servo drive

Safety relay units with test pulses can be used with the following restrictions:

–

High test pulses up to a maximum length of 1 ms

–

Low test pulses up to a maximum length of 1 ms

–

Test pulses are not simultaneous/overlapping on #STO-A/B

The safety relay units Pilz PNOZmulti, Pilz PNOZmulti Mini or SIEMENS SIMATIC ET 200SP with

PP-switching output modules, SIEMENS ET 200S, for example, would be suitable.

The input module CPX-F8DE and output module CPX-FVDA-P2 from Festo would be suitable too.

Comment: The safe output module CPX-FVDA-P2 can only switch potential-free loads. It can only be

used, therefore, in combination with an interposed relay, since #STO-A and #STO-B are referred to