11

Portable electric

drill(0

~

13mm)

Drilling hole

12

Electrical heating

device for

bearing

Heating bearing

13

Retainer pliers

Taking snap ring on/off

14

Scissors

Cutting

15

Multimeter

Resistance, voltage

Measuring

16

Hearing needle

Checking

17

Scraper

Cleaning

18

Metal brush

Cleaning

19

Air nozzle

Cleaning

20

Barrel

20L/piece

Cleaning (bearing, etc.)

21

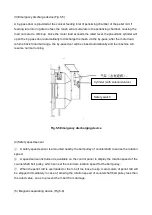

Dial gauge

indicator

Measuring clearance between roller and main shaft

bearing

22

oiler

Filling lubricant grease in main shaft and roller bearing

6.5Malfuntion and troubleshooting

No.

Trouble

Cause

Solution

1

Feed cannot enter the

ring die.

1.Feeding inlet is clogged

2. The conditioner is plugged up

3. Feeder drive doesn

’t work

1. Clean the feeding inlet

2. Clean the conditioner

3. Check the driving device of feeder

2

Material can enter the

ring die, but cannot be

pelletized.

1. The press rollers and ring die are worn

out

2. Too many die holes are clogged

3. The feed formula is changed

4. The clearance between the press

rollers and ring die is too big

5. Improper water content in feed

1. Replace the press rollers and ring die

2. Remove the feed and impurity from the die

holes

3. Install the right ring die for the feed formula

4. Readjust the clearance between the press

rollers and ring die

5. Adjust steam injection correctly