9

USE AND CARE INFORMATION

For Best Results

Start the rangehood several minutes before cooking to develop proper airflow. Allow the

rangehood to operate for several minutes after cooking is complete to clear all smoke and

odors from the kitchen.

Version 07/11 - Page 7

Rangehood Control Panel

All controls are located on the right side of the rangehood.

Light On/Off Switch

TheOn/Off switch for the halogen light is located behind the

front trim. Moving the switch to the 1 Position turns the light

On. Moving the switch to the 0 position turns the light off.

Blower Speed Switch

B in FIGURE 10

shows the speed control switch for the

blower. Moving the switch to the 1 Position turns the blower

on LOW. Moving the switch to the 2 Position turns the blower

on MEDIUM. Moving the switch to the 3 Position turns the

blower on HIGH. Moving the switch to the 0 Position turns

the blower off.

Automatic Operation

As long as the blower and light switches are on, the blower

and light will automatically operate when the visor is opened

and shut off when the visor is closed.

For Best Results

Start the rangehood several minutes before cooking to develop

proper airflow. Allow the unit to operate for several minutes

after cooking is complete to clear all smoke and odors from

the kitchen.

Cleaning

The metal grease filters should be cleaned frequently in hot

detergent solution or placed in the dishwasher. Clean exterior

surfaces with hot soapy water, and use stainless steel cleaner

on the front strip. Using abrasives and scouring agents can

scratch rangehood finishes and should not be used to clean

finished surfaces.

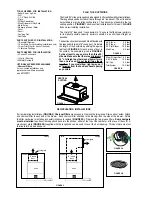

FIGURE 10

FIGURE 7

FIGURE 8

Replacing the Halogen Lamps

Before attempting to replace the lamps, make sure that

the light switch is turned off. Remove the 2 screws

(as

indicated in FIGURE 8)

that hold the light support and

gently pull the support down from the hood. Remove

the lamp from the light support and replace with new

lamp. Replace the light support and fix it into place

with the 2 screws.

An alternative method to replace the lamps is to use a

1 1/4" suction cup (

FIGURE 9

). Attach the suction cup

to the bulb and pull firmly down on the bulb and replace

with a new lamp. The hood uses a

20 Watt MR-11 type

halogen

bulb with a lens cover.

FIGURE 9

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

EN

1

1

11

USE

Control board

L

Light

Switches the lighting system on and off.

M

Motor

Switches the extractor motor on and off.

V

Speed

Sets the operating speed of the extractor:

1. Low speed, used for a continuous and silent air change in the presence of

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

�

�����

�

�

�

�

�

�

EN

1

2

12

CARE

Grease filter

s

CLEA

NING

META

LS

ELF-

SUP

PORTI

NG

GREA

SEFI

LTE

RS

•T

he

filte

rsm

ust

bec

lea

ned

eve

ry

2m

onthsof

opera

tion,

or

mor

ef

reque

ntlyf

or

partic

ularly

heav

yus

age

, a

ndc

an

be

wash

edin

ad

ish

wash

er.

•Re

mov

ethe

filte

rsone

at a

time

bypushing

the

mtow

ards

the

back

of the

group a

ndpul

ling u

pat

the sa

me ti

me.

•W

ash

thefilte

rs,ta

king

care

notto

ben

dth

em

.A

llo

wth

em

to

drybe

fore

refitting

.

•W

hen

refitting

thefilte

rs,m

ake

sure

that the

hand

leis

visible

onth

eo

utside

.

Activated charcoal filter

(Recirculating ver

sion)

The

se

filte

rs(not

supplie

dw

ithth

era

ngehood)a

re

not

was

hab

le

and

cannot

be

regenerat

ed,a

nd

must

be

replaced

appro

xim

atel

y

eve

ry

4m

onthsof

opera

tion,

orm

ore

fre

quently

with

heav

yus

-

age.

REPLACING

THE

ACTIVAT

EDCHA

RCOAL

FIL

TER

•Re

mov

ethe

meta

l gre

ase

filte

rs

•Re

mov

ethe

satura

ted

activ

ated

cha

rco

al f

iltera

sshow

n(

A

).

•Fit t

hene

wfilte

rs (

B

).z

•Rep

lace

them

etal

greas

efilters

.

�

�

Lighting

LIG

HT

REPLACEMENT

20

Whal

oge

nli

ght

.

•R

em

ove

the2

scr

ews

fix

ing

theL

igh

tings

uppor

t, a

nd

pullit

outof

fro

m the

Hoo

d.

•Ex

tract the

lam

pfr

om

theSupp

ort.

•Rep

lace

with

anot

her

of

the

samety

pe,

maki

ng

sure

that

the

two pins

are

prope

rly

ins

erte

d in

the

lam

p holde

r so

cke

t hole

s.

•Rep

lace

the

Supp

ort,

fixi

ng

iti

np

lace

with

the

two

screws re-

mov

edas

abov

e.

GREASE FILTER REMOVAL

The grease filters are removed by pressing the handle on

the right side of the filter

(FIGURE 7)

. When replacing,

make sure that the filters are properly positioned with

the handles on the right and visible. There are 2 grease

filters, one in the slide out part of the hood, the other in

the back.

USE AND CARE INFORMATION

B

Version 07/11 - Page 7

Rangehood Control Panel

All controls are located on the right side of the rangehood.

Light On/Off Switch

TheOn/Off switch for the halogen light is located behind the

front trim. Moving the switch to the 1 Position turns the light

On. Moving the switch to the 0 position turns the light off.

Blower Speed Switch

B in FIGURE 10

shows the speed control switch for the

blower. Moving the switch to the 1 Position turns the blower

on LOW. Moving the switch to the 2 Position turns the blower

on MEDIUM. Moving the switch to the 3 Position turns the

blower on HIGH. Moving the switch to the 0 Position turns

the blower off.

Automatic Operation

As long as the blower and light switches are on, the blower

and light will automatically operate when the visor is opened

and shut off when the visor is closed.

For Best Results

Start the rangehood several minutes before cooking to develop

proper airflow. Allow the unit to operate for several minutes

after cooking is complete to clear all smoke and odors from

the kitchen.

Cleaning

The metal grease filters should be cleaned frequently in hot

detergent solution or placed in the dishwasher. Clean exterior

surfaces with hot soapy water, and use stainless steel cleaner

on the front strip. Using abrasives and scouring agents can

scratch rangehood finishes and should not be used to clean

finished surfaces.

FIGURE 10

FIGURE 7

FIGURE 8

Replacing the Halogen Lamps

Before attempting to replace the lamps, make sure that

the light switch is turned off. Remove the 2 screws

(as

indicated in FIGURE 8)

that hold the light support and

gently pull the support down from the hood. Remove

the lamp from the light support and replace with new

lamp. Replace the light support and fix it into place

with the 2 screws.

An alternative method to replace the lamps is to use a

1 1/4" suction cup (

FIGURE 9

). Attach the suction cup

to the bulb and pull firmly down on the bulb and replace

with a new lamp. The hood uses a

20 Watt MR-11 type

halogen

bulb with a lens cover.

FIGURE 9

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

EN

1

1

11

USE

Control board

L

Light

Switches the lighting system on and off.

M

Motor

Switches the extractor motor on and off.

V

Speed

Sets the operating speed of the extractor:

1. Low speed, used for a continuous and silent air change in the presence of

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

�

�����

�

�

�

�

�

�

EN

1

2

12

CARE

Grease filter

s

CLEA

NING

META

LS

ELF-

SUP

PORTI

NG

GREA

SEFI

LTE

RS

•T

he

filte

rsm

ust

bec

lea

ned

eve

ry

2m

onthsof

opera

tion,

or

mor

ef

reque

ntlyf

or

partic

ularly

heav

yus

age

, a

ndc

an

be

wash

edin

ad

ish

wash

er.

•Re

mov

ethe

filte

rsone

at a

time

bypushing

the

mtow

ards

the

back

of the

group a

ndpul

ling u

pat

the sa

me ti

me.

•W

ash

thefilte

rs,ta

king

care

notto

ben

dth

em

.A

llo

wth

em

to

drybe

fore

refitting

.

•W

hen

refitting

thefilte

rs,m

ake

sure

that the

hand

leis

visible

onth

eo

utside

.

Activated charcoal filter

(Recirculating ver

sion)

The

se

filte

rs(not

supplie

dw

ithth

era

ngehood)a

re

not

was

hab

le

and

cannot

be

regenerat

ed,a

nd

must

be

replaced

appro

xim

atel

y

eve

ry

4m

onthsof

opera

tion,

orm

ore

fre

quently

with

heav

yus

-

age.

REPLACING

THE

ACTIVAT

EDCHA

RCOAL

FIL

TER

•Re

mov

ethe

meta

l gre

ase

filte

rs

•Re

mov

ethe

satura

ted

activ

ated

cha

rco

al f

iltera

sshow

n(

A

).

•Fit t

hene

wfilte

rs (

B

).z

•Rep

lace

them

etal

greas

efilters

.

�

�

Lighting

LIG

HT

REPLACEMENT

20

Whal

oge

nli

ght

.

•R

em

ove

the2

scr

ews

fix

ing

theL

igh

tings

uppor

t, a

nd

pullit

outof

fro

m the

Hoo

d.

•Ex

tract the

lam

pfr

om

theSupp

ort.

•Rep

lace

with

anot

her

of

the

samety

pe,

maki

ng

sure

that

the

two pins

are

prope

rly

ins

erte

d in

the

lam

p holde

r so

cke

t hole

s.

•Rep

lace

the

Supp

ort,

fixi

ng

iti

np

lace

with

the

two

screws re-

mov

edas

abov

e.

GREASE FILTER REMOVAL

The grease filters are removed by pressing the handle on

the right side of the filter

(FIGURE 7)

. When replacing,

make sure that the filters are properly positioned with

the handles on the right and visible. There are 2 grease

filters, one in the slide out part of the hood, the other in

the back.

USE AND CARE INFORMATION

B

Version 07/11 - Page 7

Rangehood Control Panel

All controls are located on the right side of the rangehood.

Light On/Off Switch

TheOn/Off switch for the halogen light is located behind the

front trim. Moving the switch to the 1 Position turns the light

On. Moving the switch to the 0 position turns the light off.

Blower Speed Switch

B in FIGURE 10

shows the speed control switch for the

blower. Moving the switch to the 1 Position turns the blower

on LOW. Moving the switch to the 2 Position turns the blower

on MEDIUM. Moving the switch to the 3 Position turns the

blower on HIGH. Moving the switch to the 0 Position turns

the blower off.

Automatic Operation

As long as the blower and light switches are on, the blower

and light will automatically operate when the visor is opened

and shut off when the visor is closed.

For Best Results

Start the rangehood several minutes before cooking to develop

proper airflow. Allow the unit to operate for several minutes

after cooking is complete to clear all smoke and odors from

the kitchen.

Cleaning

The metal grease filters should be cleaned frequently in hot

detergent solution or placed in the dishwasher. Clean exterior

surfaces with hot soapy water, and use stainless steel cleaner

on the front strip. Using abrasives and scouring agents can

scratch rangehood finishes and should not be used to clean

finished surfaces.

FIGURE 10

FIGURE 7

FIGURE 8

Replacing the Halogen Lamps

Before attempting to replace the lamps, make sure that

the light switch is turned off. Remove the 2 screws

(as

indicated in FIGURE 8)

that hold the light support and

gently pull the support down from the hood. Remove

the lamp from the light support and replace with new

lamp. Replace the light support and fix it into place

with the 2 screws.

An alternative method to replace the lamps is to use a

1 1/4" suction cup (

FIGURE 9

). Attach the suction cup

to the bulb and pull firmly down on the bulb and replace

with a new lamp. The hood uses a

20 Watt MR-11 type

halogen

bulb with a lens cover.

FIGURE 9

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

EN

1

1

11

USE

Control board

L

Light

Switches the lighting system on and off.

M

Motor

Switches the extractor motor on and off.

V

Speed

Sets the operating speed of the extractor:

1. Low speed, used for a continuous and silent air change in the presence of

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

�

�����

�

�

�

�

�

�

EN

1

2

12

CARE

Grease filter

s

CLEA

NING

META

LS

ELF-

SUP

PORTI

NG

GREA

SEFI

LTE

RS

•T

he

filte

rsm

ust

bec

lea

ned

eve

ry

2m

onthsof

opera

tion,

or

mor

ef

reque

ntlyf

or

partic

ularly

heav

yus

age

, a

ndc

an

be

wash

edin

ad

ish

wash

er.

•Re

mov

ethe

filte

rsone

at a

time

bypushing

the

mtow

ards

the

back

of the

group a

ndpul

ling u

pat

the sa

me ti

me.

•W

ash

thefilte

rs,ta

king

care

notto

ben

dth

em

.A

llo

wth

em

to

drybe

fore

refitting

.

•W

hen

refitting

thefilte

rs,m

ake

sure

that the

hand

leis

visible

onth

eo

utside

.

Activated charcoal filter

(Recirculating ver

sion)

The

se

filte

rs(not

supplie

dw

ithth

era

ngehood)a

re

not

was

hab

le

and

cannot

be

regenerat

ed,a

nd

must

be

replaced

appro

xim

atel

y

eve

ry

4m

onthsof

opera

tion,

orm

ore

fre

quently

with

heav

yus

-

age.

REPLACING

THE

ACTIVAT

EDCHA

RCOAL

FIL

TER

•Re

mov

ethe

meta

l gre

ase

filte

rs

•Re

mov

ethe

satura

ted

activ

ated

cha

rco

al f

iltera

sshow

n(

A

).

•Fit t

hene

wfilte

rs (

B

).z

•Rep

lace

them

etal

greas

efilters

.

�

�

Lighting

LIG

HT

REPLACEMENT

20

Whal

oge

nli

ght

.

•R

em

ove

the2

scr

ews

fix

ing

theL

igh

tings

uppor

t, a

nd

pullit

outof

fro

m the

Hoo

d.

•Ex

tract the

lam

pfr

om

theSupp

ort.

•Rep

lace

with

anot

her

of

the

samety

pe,

maki

ng

sure

that

the

two pins

are

prope

rly

ins

erte

d in

the

lam

p holde

r so

cke

t hole

s.

•Rep

lace

the

Supp

ort,

fixi

ng

iti

np

lace

with

the

two

screws re-

mov

edas

abov

e.

GREASE FILTER REMOVAL

The grease filters are removed by pressing the handle on

the right side of the filter

(FIGURE 7)

. When replacing,

make sure that the filters are properly positioned with

the handles on the right and visible. There are 2 grease

filters, one in the slide out part of the hood, the other in

the back.

USE AND CARE INFORMATION

B

Version 07/11 - Page 7

Rangehood Control Panel

All controls are located on the right side of the rangehood.

Light On/Off Switch

TheOn/Off switch for the halogen light is located behind the

front trim. Moving the switch to the 1 Position turns the light

On. Moving the switch to the 0 position turns the light off.

Blower Speed Switch

B in FIGURE 10

shows the speed control switch for the

blower. Moving the switch to the 1 Position turns the blower

on LOW. Moving the switch to the 2 Position turns the blower

on MEDIUM. Moving the switch to the 3 Position turns the

blower on HIGH. Moving the switch to the 0 Position turns

the blower off.

Automatic Operation

As long as the blower and light switches are on, the blower

and light will automatically operate when the visor is opened

and shut off when the visor is closed.

For Best Results

Start the rangehood several minutes before cooking to develop

proper airflow. Allow the unit to operate for several minutes

after cooking is complete to clear all smoke and odors from

the kitchen.

Cleaning

The metal grease filters should be cleaned frequently in hot

detergent solution or placed in the dishwasher. Clean exterior

surfaces with hot soapy water, and use stainless steel cleaner

on the front strip. Using abrasives and scouring agents can

scratch rangehood finishes and should not be used to clean

finished surfaces.

FIGURE 10

FIGURE 7

FIGURE 8

Replacing the Halogen Lamps

Before attempting to replace the lamps, make sure that

the light switch is turned off. Remove the 2 screws

(as

indicated in FIGURE 8)

that hold the light support and

gently pull the support down from the hood. Remove

the lamp from the light support and replace with new

lamp. Replace the light support and fix it into place

with the 2 screws.

An alternative method to replace the lamps is to use a

1 1/4" suction cup (

FIGURE 9

). Attach the suction cup

to the bulb and pull firmly down on the bulb and replace

with a new lamp. The hood uses a

20 Watt MR-11 type

halogen

bulb with a lens cover.

FIGURE 9

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

EN

1

1

11

USE

Control board

L

Light

Switches the lighting system on and off.

M

Motor

Switches the extractor motor on and off.

V

Speed

Sets the operating speed of the extractor:

1. Low speed, used for a continuous and silent air change in the presence of

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

�

�����

�

�

�

�

�

�

EN

1

2

12

CARE

Grease filter

s

CLEA

NING

META

LS

ELF-

SUP

PORTI

NG

GREA

SEFI

LTE

RS

•T

he

filte

rsm

ust

bec

lea

ned

eve

ry

2m

onthsof

opera

tion,

or

mor

ef

reque

ntlyf

or

partic

ularly

heav

yus

age

, a

ndc

an

be

wash

edin

ad

ish

wash

er.

•Re

mov

ethe

filte

rsone

at a

time

bypushing

the

mtow

ards

the

back

of the

group a

ndpul

ling u

pat

the sa

me ti

me.

•W

ash

thefilte

rs,ta

king

care

notto

ben

dth

em

.A

llo

wth

em

to

drybe

fore

refitting

.

•W

hen

refitting

thefilte

rs,m

ake

sure

that the

hand

leis

visible

onth

eo

utside

.

Activated charcoal filter

(Recirculating ver

sion)

The

se

filte

rs(not

supplie

dw

ithth

era

ngehood)a

re

not

was

hab

le

and

cannot

be

regenerat

ed,a

nd

must

be

replaced

appro

xim

atel

y

eve

ry

4m

onthsof

opera

tion,

orm

ore

fre

quently

with

heav

yus

-

age.

REPLACING

THE

ACTIVAT

EDCHA

RCOAL

FIL

TER

•Re

mov

ethe

meta

l gre

ase

filte

rs

•Re

mov

ethe

satura

ted

activ

ated

cha

rco

al f

iltera

sshow

n(

A

).

•Fit t

hene

wfilte

rs (

B

).z

•Rep

lace

them

etal

greas

efilters

.

�

�

Lighting

LIG

HT

REPLACEMENT

20

Whal

oge

nli

ght

.

•R

em

ove

the2

scr

ews

fix

ing

theL

igh

tings

uppor

t, a

nd

pullit

outof

fro

m the

Hoo

d.

•Ex

tract the

lam

pfr

om

theSupp

ort.

•Rep

lace

with

anot

her

of

the

samety

pe,

maki

ng

sure

that

the

two pins

are

prope

rly

ins

erte

d in

the

lam

p holde

r so

cke

t hole

s.

•Rep

lace

the

Supp

ort,

fixi

ng

iti

np

lace

with

the

two

screws re-

mov

edas

abov

e.

GREASE FILTER REMOVAL

The grease filters are removed by pressing the handle on

the right side of the filter

(FIGURE 7)

. When replacing,

make sure that the filters are properly positioned with

the handles on the right and visible. There are 2 grease

filters, one in the slide out part of the hood, the other in

the back.

USE AND CARE INFORMATION

B

Version 07/11 - Page 7

Rangehood Control Panel

All controls are located on the right side of the rangehood.

Light On/Off Switch

TheOn/Off switch for the halogen light is located behind the

front trim. Moving the switch to the 1 Position turns the light

On. Moving the switch to the 0 position turns the light off.

Blower Speed Switch

B in FIGURE 10

shows the speed control switch for the

blower. Moving the switch to the 1 Position turns the blower

on LOW. Moving the switch to the 2 Position turns the blower

on MEDIUM. Moving the switch to the 3 Position turns the

blower on HIGH. Moving the switch to the 0 Position turns

the blower off.

Automatic Operation

As long as the blower and light switches are on, the blower

and light will automatically operate when the visor is opened

and shut off when the visor is closed.

For Best Results

Start the rangehood several minutes before cooking to develop

proper airflow. Allow the unit to operate for several minutes

after cooking is complete to clear all smoke and odors from

the kitchen.

Cleaning

The metal grease filters should be cleaned frequently in hot

detergent solution or placed in the dishwasher. Clean exterior

surfaces with hot soapy water, and use stainless steel cleaner

on the front strip. Using abrasives and scouring agents can

scratch rangehood finishes and should not be used to clean

finished surfaces.

FIGURE 10

FIGURE 7

FIGURE 8

Replacing the Halogen Lamps

Before attempting to replace the lamps, make sure that

the light switch is turned off. Remove the 2 screws

(as

indicated in FIGURE 8)

that hold the light support and

gently pull the support down from the hood. Remove

the lamp from the light support and replace with new

lamp. Replace the light support and fix it into place

with the 2 screws.

An alternative method to replace the lamps is to use a

1 1/4" suction cup (

FIGURE 9

). Attach the suction cup

to the bulb and pull firmly down on the bulb and replace

with a new lamp. The hood uses a

20 Watt MR-11 type

halogen

bulb with a lens cover.

FIGURE 9

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

EN

1

1

11

USE

Control board

L

Light

Switches the lighting system on and off.

M

Motor

Switches the extractor motor on and off.

V

Speed

Sets the operating speed of the extractor:

1. Low speed, used for a continuous and silent air change in the presence of

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

�

�����

�

�

�

�

�

�

EN

1

2

12

CARE

Grease filter

s

CLEA

NING

META

LS

ELF-

SUP

PORTI

NG

GREA

SEFI

LTE

RS

•T

he

filte

rsm

ust

bec

lea

ned

eve

ry

2m

onthsof

opera

tion,

or

mor

ef

reque

ntlyf

or

partic

ularly

heav

yus

age

, a

ndc

an

be

wash

edin

ad

ish

wash

er.

•Re

mov

ethe

filte

rsone

at a

time

bypushing

the

mtow

ards

the

back

of the

group a

ndpul

ling u

pat

the sa

me ti

me.

•W

ash

thefilte

rs,ta

king

care

notto

ben

dth

em

.A

llo

wth

em

to

drybe

fore

refitting

.

•W

hen

refitting

thefilte

rs,m

ake

sure

that the

hand

leis

visible

onth

eo

utside

.

Activated charcoal filter

(Recirculating ver

sion)

The

se

filte

rs(not

supplie

dw

ithth

era

ngehood)a

re

not

was

hab

le

and

cannot

be

regenerat

ed,a

nd

must

be

replaced

appro

xim

atel

y

eve

ry

4m

onthsof

opera

tion,

orm

ore

fre

quently

with

heav

yus

-

age.

REPLACING

THE

ACTIVAT

EDCHA

RCOAL

FIL

TER

•Re

mov

ethe

meta

l gre

ase

filte

rs

•Re

mov

ethe

satura

ted

activ

ated

cha

rco

al f

iltera

sshow

n(

A

).

•Fit t

hene

wfilte

rs (

B

).z

•Rep

lace

them

etal

greas

efilters

.

�

�

Lighting

LIG

HT

REPLACEMENT

20

Whal

oge

nli

ght

.

•R

em

ove

the2

scr

ews

fix

ing

theL

igh

tings

uppor

t, a

nd

pullit

outof

fro

m the

Hoo

d.

•Ex

tract the

lam

pfr

om

theSupp

ort.

•Rep

lace

with

anot

her

of

the

samety

pe,

maki

ng

sure

that

the

two pins

are

prope

rly

ins

erte

d in

the

lam

p holde

r so

cke

t hole

s.

•Rep

lace

the

Supp

ort,

fixi

ng

iti

np

lace

with

the

two

screws re-

mov

edas

abov

e.

GREASE FILTER REMOVAL

The grease filters are removed by pressing the handle on

the right side of the filter

(FIGURE 7)

. When replacing,

make sure that the filters are properly positioned with

the handles on the right and visible. There are 2 grease

filters, one in the slide out part of the hood, the other in

the back.

USE AND CARE INFORMATION

B

Содержание Cristal 24 SS

Страница 35: ...35...

Страница 36: ...991 0531 907_01 180312 D00004241_00...