6

EBP 100/200 Series • Setup Guide (Continued)

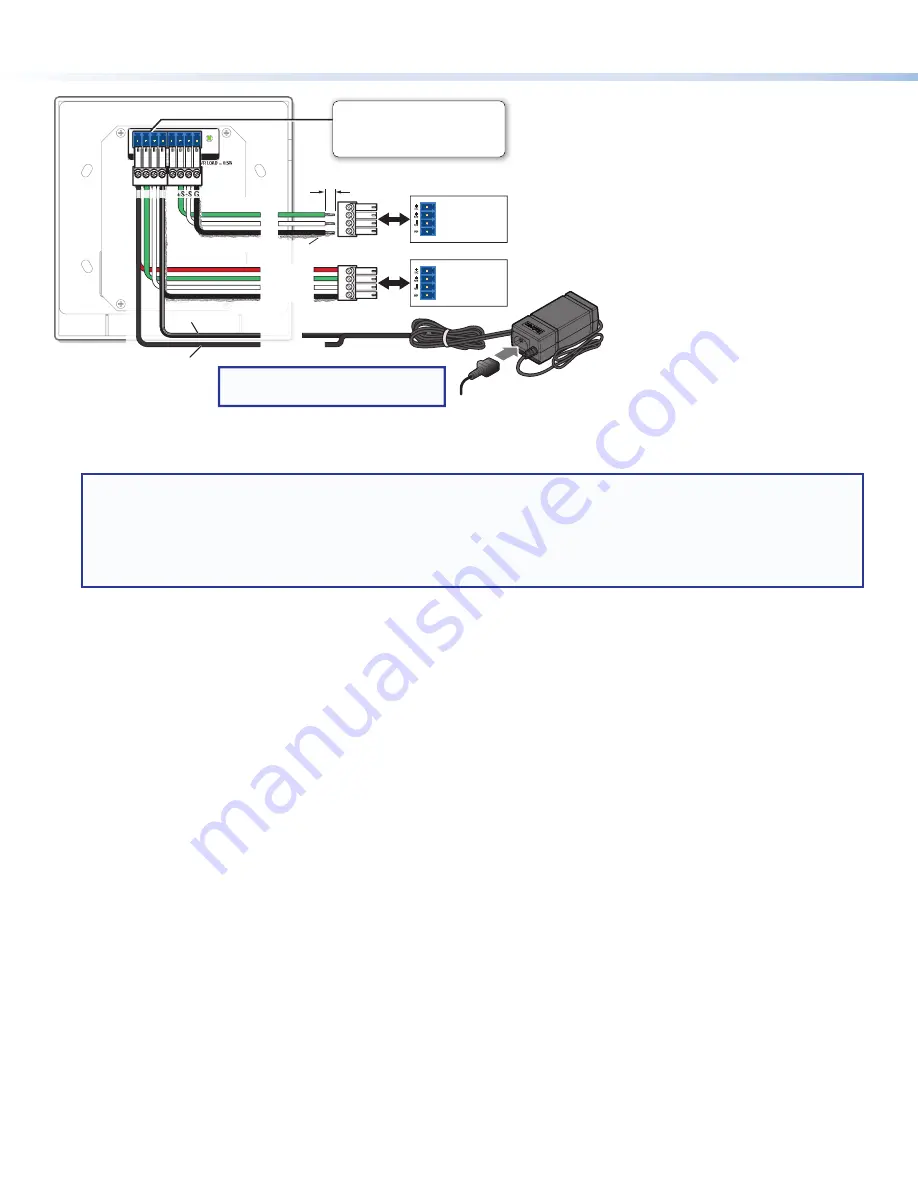

eBUS port on

an IPCP Pro

control

processor

+

V

+

S

G

– S

eBUS port on

an EBP or

other eBUS

endpoint

+

V

+

S

G

– S

G

-S

+S

G

Ground

+

Signal

-

Signal

+

12 VDC

+V

G

-S

+S

G

-S

+S

+V

-S

+S

Tie drain wires to ground.

Ground

all devices.

– Return

+12 VDC input

Ridged

Smooth

1A MA

X

100-240V 50-60H

z

External

Power Supply

(12 VDC, 1 A max.,

Extron P/N 28-071-57LF)

EBP 100

Rear Panel

NOTE:

Check the polarity of the power

supply before connecting it to the EBP.

Power Input,

External Power Supply (optional)

• Connect to an Extron 12 VDC, 1 A,

power supply.

3/16" (5 mm) Max.

Figure 6.

Cabling EBP Panels with an Extron 12 VDC, 1 A Power Supply

Step 6: Configure the System

NOTES:

•

System configuration requires an IP network connection to the IPCP Pro. See the

IPCP Pro Series User Guide

for

information about the control processors and their ports.

•

EBP bus ID DIP switches should be set prior to uploading the configuration to the IPCP Pro.

•

See the

Global Configurator Help

file as needed for step-by-step instructions and detailed information. The help file for

GC includes an introduction to the software, and how to start a project and configuration.

1.

Create a new Global Configurator Plus or Professional project and configure the controller and any eBUS devices. The

configuration tells the controller how its ports function; how to control other products; what to monitor; when to do things;

and whom to notify, how, and under what circumstances.

a.

Configure ports on the control processor.

•

Select device drivers and link them to each assigned port.

•

Configure settings (serial protocol, relay behavior, digital input, volume control settings) as needed.

b.

Set up monitors, schedules, macros, and local variables.

c.

Set up the eBUS button panel buttons: assign appropriate commands and actions, macros, timers, local variables

monitors, or feedback to the buttons.

2.

Save the project.

3.

Build and upload the system configuration to the control processor.

Step 7: Test and Troubleshoot

1.

Verify that the DIP switches on the EBPs are set to the desired address on each unit and that there are no DIP switch address

conflicts in the system. As mentioned in the rear panel features diagram in

on page 4, the

eBUS LED lights steadily (solid) when power and communication are present and there are no bus ID address conflicts.

2.

Verify that cables to and from the EBPs are wired the same at each end (pin 1 to pin 1, pin 2 to pin 2, and so forth).

3.

Test the system.

•

Press buttons on the EBPs and ensure the buttons light as desired and that the appropriate control commands or

functions are triggered.

•

Ensure that the audio output responds correctly to the

volume

knob or button. Also ensure that the volume LEDs light

correctly as you increase or decrease the audio gain.

4.

Make adjustments to wiring, bus ID address, or system configuration as needed. Remember that the rear panel ports and DIP

switches will not be accessible after the EBP is mounted. If needed, upload a revised configuration to the control processor.

If you have questions during installation and setup, call the

Extron S3 Sales & Technical Support Hotline

or the Extron S3

Control Systems Support Hotline (1.800.633.9877).