- 28 -

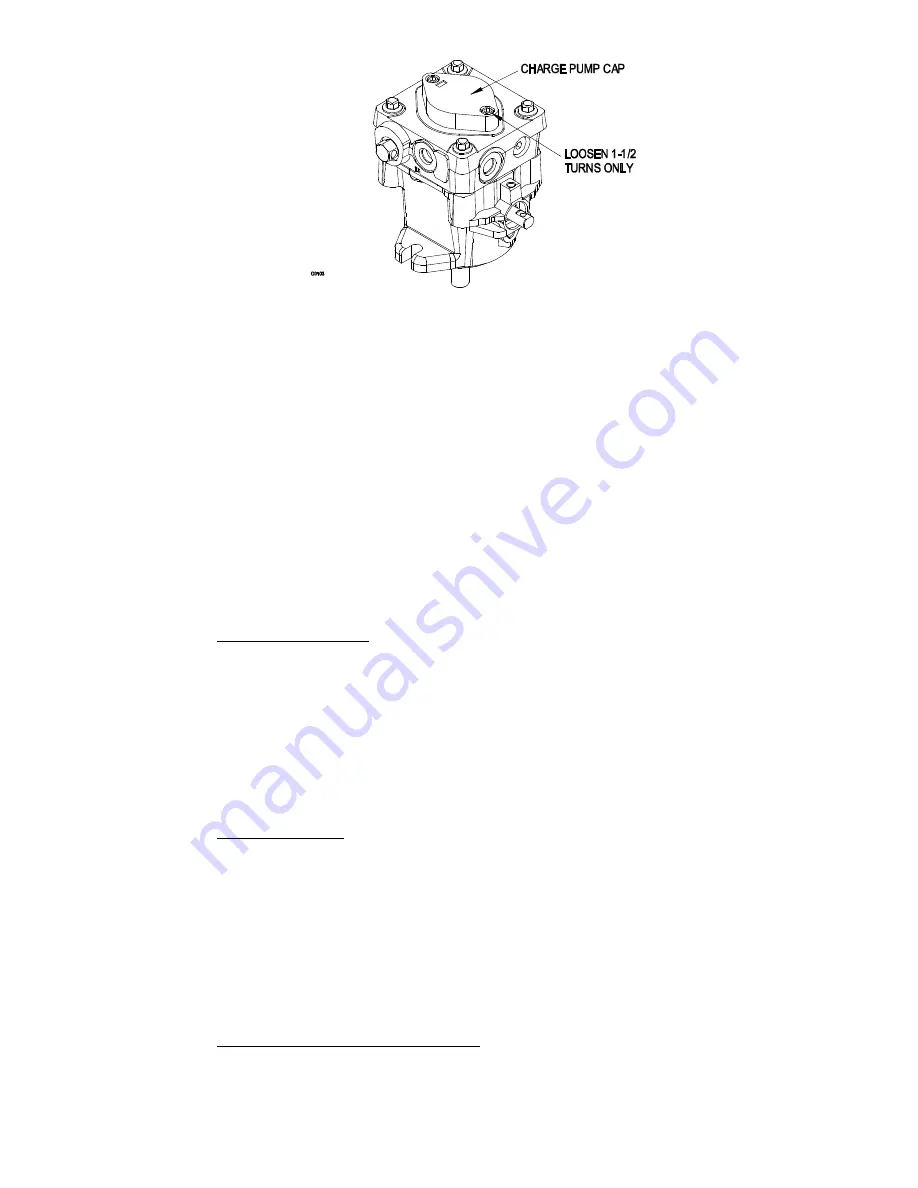

FIGURE 8

CHARGE PUMP LOCATION

e) To “prime” charge pump, loosen two hex socket head capscrews (shown in

Figure 11)

1-1/2 turns only.

Make sure engine is not running

.

Lift

charge pump housing upward and wait for a steady flow of oil to flow out

from under housing.

Retighten capscrews

. Do this for both pumps.

Note: Hydraulic reservoir can be pressurized to up to 5 psi (35 kPa) to

speed this process.

f)

If either drive wheel still does not rotate, stop and repeat Steps (d) through

(e) above for the respective pump. If tires rotate slowly, the system may

prime after additional running. Check oil level as stated in Section 5.1.8.

g) Allow unit to run several minutes after the charge pumps are “primed” with

drive system in the full speed position.

Check oil level as stated in Section 5.1.8.

h) Check hydro drive linkage adjustment as stated in Section 5.2.6.

5.1.11

Check tire pressures.

Service Interval:

Pneumatic (air-filled) Drive Tires-

40 hrs.

Semi-pneumatic Caster Tires – No maintenance

a) Stop engine and wait for all moving parts to stop. Remove ignition key or

spark plug wire(s). Check air pressure in drive tires; recommended tire

pressure is 12-16 psi (83-110 kPa).

b) Inflate tires to pressures stated above. Measure the circumference of each

drive tire. Adjust tire pressures within the above range to try to make tire

circumferences match as closely as possible.

5.1.12

Inspect Belt wear.

Service Interval:

40 hrs.

a) Stop engine and wait for all moving parts to stop. Remove ignition key or

spark plug wire(s).

b) Remove deck support belt shield to check mower deck drive belt condition.

c) Look under engine deck to check the pump drive and clutching belt

condition.

d) Check all idler arms to be sure they pivot freely. Disassemble, clean and

grease pivot bushings if necessary.

5.1.13

Inspect PTO Clutching Belt Tension.

Service Interval:

Check every 2 hrs. for first 8 hrs. operation then check

every 40 hrs. thereafter.

a)

Stop engine and wait for all moving parts to stop.

Содержание TT4819KAC

Страница 1: ...For Serial Nos 440 000 Higher Part No 103 4871 ...

Страница 44: ... 39 8 WIRING DIAGRAMS ...

Страница 45: ... 40 9 HYDRAULIC DIAGRAM ...