- 36 -

3. Make this adjustment for both sides.

e) Tracking Adjustment

1. Stop engine and wait for all moving parts to stop. Raise the rear of the

machine, remove jack stands and carefully lower the machine to the ground.

(Check the drive tire pressure and tire circumference. (See 5.1.11.)

2. Run the unit and observe the tracking on a level, smooth, hard surface

such as concrete or asphalt.

3. If the unit tracks to one side or the other, turn the quick track knob.

Turn the knob right to “steer” right; turn the knob left to “steer” left.

5.2.7 Hydro Pump Spring Tension Setting

a)

For medium or heavy duty drive conditions such as operation with a sulky

on steep slopes, a higher spring force may be required on the hydro pump

control arms to prevent the drive system from stalling.

b)

For a heavier drive setting, relocate the spring anchor link to either the

“medium” or “heavy duty” positions as shown in Figure 16. The spring

anchor links are attached to the upper rear corner of the hydro drive shields

on the left and right hand sides of the machine.

Note: In the “medium” or “heavy duty” positions, the drive lever forces at

the upper handle will also be increased.

FIGURE 16

HYDRO PUMP SPRING TENSION SETTING

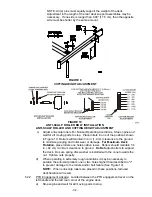

5.2.8

Park Brake Adjustment:

a)

Shut off engine and wait for all moving parts to stop.

b)

Disengage the park brake.

c)

Remove the hairpin in the park brake linkage. Turn the linkage in the yoke

until there is 3/16” (.48 cm) to 1/4” (.64 cm) clearance between the park brake

tire bars and the tires with the park brake disengaged. Re-install the hairpin.

6. WASTE DISPOSAL

6.1 MOTOR OIL DISPOSAL

Engine oil and hydraulic oil are both pollutants to the environment. Dispose of used oil at

a certified recycling center or according to your state and local regulations.

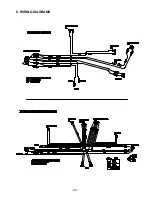

Содержание TT4819KAC

Страница 1: ...For Serial Nos 440 000 Higher Part No 103 4871 ...

Страница 44: ... 39 8 WIRING DIAGRAMS ...

Страница 45: ... 40 9 HYDRAULIC DIAGRAM ...