[Bulbdial Assembly Guide]

[6]

(

3)

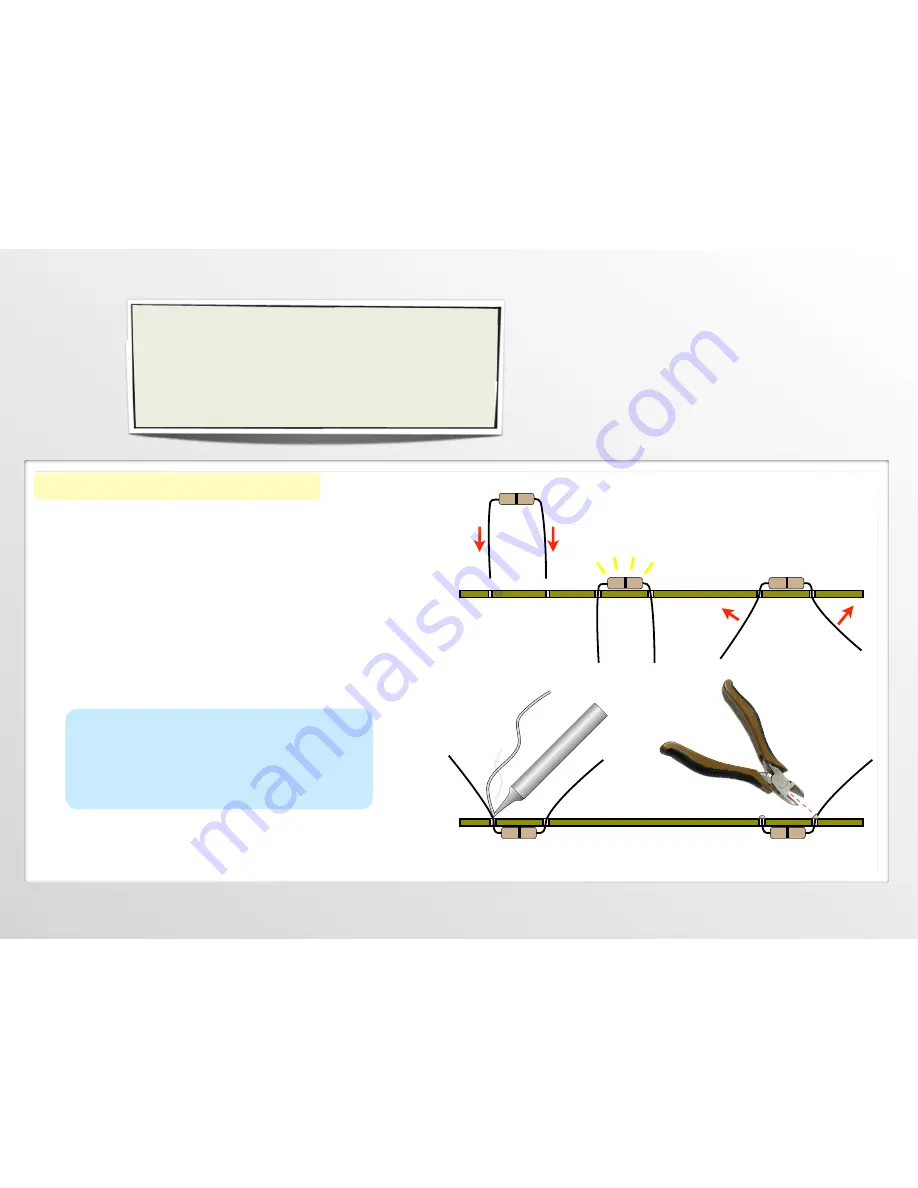

Solder!

(4)

Clip!

(1)

Insert!

(2)

Bend!

45°, max

(0)

. Pre-form the leads of components if needed.

(For example, like the jumper in step 3.)

(1)

. Insert each component into the circuit board, from

the top, at its given location. Push it flush to the board

(Note that some components, like the chip and LEDs,

need to be inserted with a particular orientation.)

(2)

. If your component has flexible leads,

gently

bend the leads

out, up to 45

°, to hold it in place while you solder.

(3)

. One at a time, from the back side, solder the leads of

the component to the circuit board.

(4)

. If the component has long and/or or flexible leads, clip off

the extra length, close to the board. (But not so close that

you’re clipping the board itself.)

• Your tip

needs

to be

shiny

(tinned). If not, melt some fresh

solder against it and

quickly

swipe clean on a wet sponge.

• Place the solder against the joint that you wish to connect.

• Touch the iron to the solder and joint for about one second.

Count it out: “one thousand one.”

• The solder should melt to the joint and leave a shiny

wet-looking joint. If not, let it cool and try again.

STEP 4a: Some hints on soldering

Adding components to the circuit board

As the old Heathkit manuals say, “it is interesting to note” that

the vast majority of problems reported with soldering kits turn

out to be due to unreliable solder connections.

Before we go further, here’s a quick refresher, with our

suggested procedures for adding components to the circuit

board. These procedures apply to most components in the kit.

TO BE CONTINUED...