59

ENGLISH

CHAPTER 15 ELECTRICAL WIRING AND CONNECTIONS

The electrical system and connection must be carried out by qualified personnel. Before installation,

measure the impedance of the network, the impedance value for the connection to the network must

not exceed 0.075 ohm.

For safety reasons you must follow these guidelines:

- verify that the sizing of the electrical system is suitable for the power consumption of the blast chiller

and that it provides for a differential switch (circuit breaker)

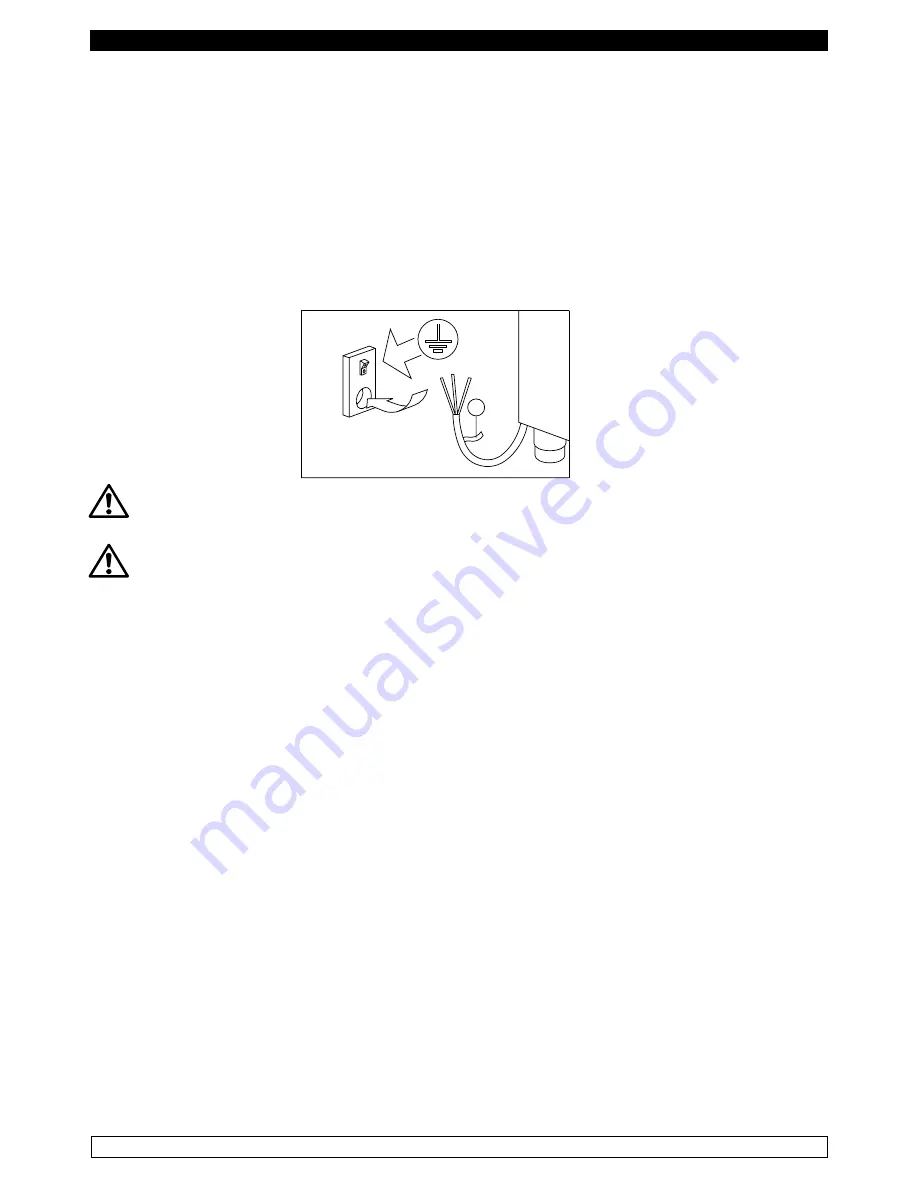

- All the chillers are supplied to no electrical plug (Figure 8), for connection to carefully observe what

described on the label on the electrical connection cable (5)

5

Fig.8

The power cord has the connection type “Y” and it can be replaced exclusively by the

manufacturer or authorized technical service

It is essential to correctly connect the blast chiller to an efficient earthing system carried out

as specified by the applicable provisions of law.

CHAPTER 16 INSTALLATION OPERATIONS

It is important, in order to prevent errors and accidents, to perform a series of checks before starting

up the blast chiller in order to identify any damage incurred during transport, handling and connection.

Checks to be performed:

- check the integrity of the power cord (it must not have suffered abrasions or cuts)

- check the solidity of the legs, door hinges, shelf supports

- check the integrity of the internal and external parts (pipes, heating elements, fans, electrical

components, etc.) and their fixing

- check that the seals of the doors have not been damaged (cuts or abrasions) and close with an

airtight seal

- check the integrity of the pipes and fittings

CHAPTER 17 REINSTALLATION

It is necessary to comply with the following procedure:

- disconnect the power cord from the power outlet

- the handling should be carried out as described in chapter 14

- for a new placement and connection, please refer to par. 14.1

- proceed to the possible recovery of the refrigerant gas in accordance with the regulations in force

in your country