29

BASIC MIG OPERATION

If the burn back control is set too long it can cause the wire to burn

back into the tip itself and welding of the wire to the tip. Begin with

setting the unit for a little less than a quarter second. If the burn

back control is set correctly, it will leave about

1/4”

-

3/8”

wire stick-

ing out beyond the contact tip. If a large ball develops on the end

of the wire, reduce the burn back time so that it creates a balance

between ball size and stick

-

out. The short amount of post flow that

is built into the programming of the Power i

-

MIG helps shield while

the wire is burning back. This helps control balling and prevents

oxidation during burn back. This is a unique feature that is not

found in many welders with burn back control. Burnback control

without post flow can cause erratic restarts due to the oxidized or

over

-

balled wire tip.

Even with the burn back control properly adjusted, due to operator

error, an occasional quick trim of the wire may be necessary for

best arc starts. But overall, when used in a production setting or in

a fabrication shop, the burn back control can save on labor and

aggravation.

Starting the Arc and Welding.

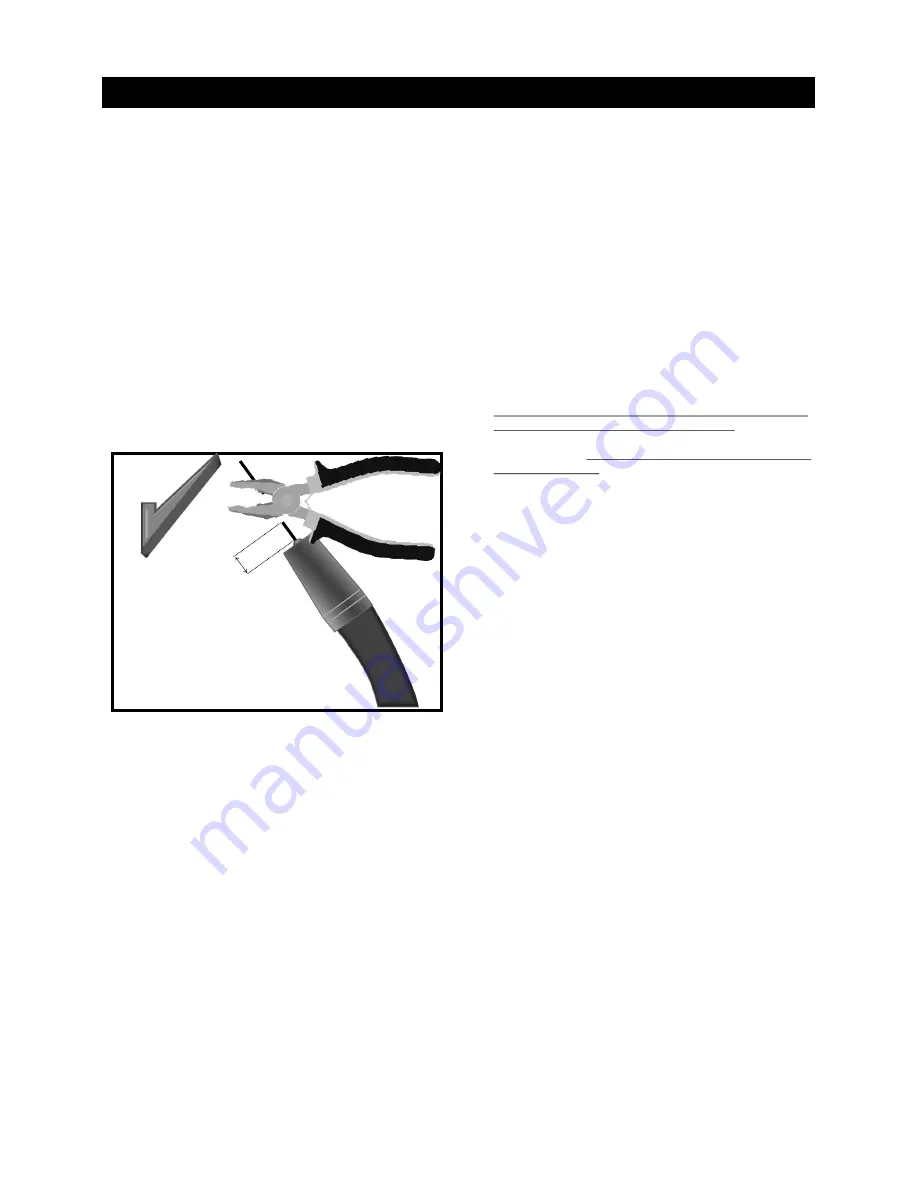

Starting the arc is a relatively simple process. Before beginning,

the wire should initially be trimmed to between 1/4 to

3/8”.

Once

the wire is trimmed, the gun should be firmly grasped to prevent a

phenomenon often referred to as

“

machine gunning

”.

A light

grasp, especially at start, can cause the arc to stutter as the wire

pushes back on the gun, lengthening the wire stick

-

out and creating

an irregular start and porous weld.

The end of the wire should be positioned just barely above the

metal when the trigger is pulled for the cleanest start. This will

position the end of the contact tip about

1/2”

above the weld. The

gun should be in the vertical position, with no more than 5 degrees

lean in either side to side direction. Holding the wire too far off

from the metal will result in rough starting and too long of wire stick

out.

Once the arc has been established, the gun can then either be

pushed or pulled in the direction of the weld. In either case, the

gun nozzle should be positioned directly over the weld without

angling the wire to one side or the other of the weld as already

mentioned. The gun should have no more than 15 degrees lean

pointed into (push) or pointed away from (pull) the direction of

travel. In most cases a push motion is desired. However, a lot of

texts offer conflicting information on whether to push or to pull the

gun. In reality, both are correct if used correctly and with each

having particular strength and weakness. Either one done with too

much gun angle will result in undesirable results. Most open

-

minded people who are well versed in MIG quickly develop a

sense of when to push and when to pull the gun. Even for novic-

es, a sense of when to push and pull the gun comes quickly with a

little practice. Pushing can result in shallower penetration but the

molten puddle is easier to see and the arc sits easily on the leading

edge. It will usually leave a aesthetically pleasing bead. However,

be careful to prevent the gun from leaning toward or away from the

direction of travel too much as spatter will increase and shielding

gas flow may become turbulent, creating porosity in the weld.

Pulling will result in deeper penetration, but can result in a narrow

bead without much side fusion. It also can leave an undesirable

humped appearance if not done correctly or if travel is too slow.

Whenever MIG welding with Aluminum, whether with the standard

MIG gun or the Spool gun ALWAYS push the gun.

During Pulse

Welding, a Push angle is recommended wherever possible, regard-

less of metal type.

If using Flux Core, a dragging motion is almost

always recommended.

Weaving (oscillating the torch from side to side in one pattern or

the other), particularly a MIG bead, is a topic of controversy as

much as whether to push or pull the MIG gun. Stringer beads are

often best for novice welders. Stringers are simply straight beads

that move forward with little or no side to side travel or oscillation.

These will offer the soundest welds for a beginner. Stringer welds

leave little or no room for contaminates to enter the weld and are

the fastest to produce without creating an opportunity for cold lap.

Moving too quickly however with a stringer can create undercut

which will weaken the weld. The best policy is to move a slow

steady speed, making sure the sides of the weld are filled. If under-

cut is present, it is either from too much voltage or moving before

the wire has time to fill the area the arc has melted.

Think of weaving as a method of

“

sewing

”

the metal together. If

weaving is of interest to you, start with the basic weave pattern.

Simple weaves using one variation or the other of a cursive

“

e

”

motion are best to begin with. Other weave patterns can be used

of course. C

’

s, V

’

S, U

’

s , Triangles and many more weave patterns

can be used depending upon the application. Weaves are em-

ployed for a number of reasons. Weaves are often considered to

have a more pleasing appearance and can help bridge gaps where

fit up is a problem. A weave is also frequently used to manage heat

build up. For example: when welding vertically weaves are almost

always used to prevent the molten metal from sagging due to the

force of gravity. The major drawback of weaving is that it introduc-

es a greater possibility of getting inclusions and other forms of

contamination in the weld. Properly done weaving is a valuable

tool, but it must be practiced before employing it in any structural

or critical application.

Metal Cleaning.

MIG welding requires a well prepped surface to obtain a sound

weld. The removal of paint, rust mill scale, or other contaminate

such as grease should be done before welding. Stick welding is

more forgiving of rust and mill scale, but when MIG welding, con-

taminates will result in porosity and inclusions in the weld, weaken-

ing it. A grinder will usually prep the metal sufficiently to remove

oxidation and paint. However, to remove grease, a degreaser such

as acetone should be used. Do not use any degreaser such a brake

Section 2 Setup Guide

1/4”

-

3/8”

(6mm–

9mm)

Содержание Power i-MIG 353DPi

Страница 47: ...47...