LUBE-MASTER R10

3(21)

1. Introduction

The LUBE-Master TSM module, (

T

ank

Surveillance M

odule), is used to control pumps and/or measure levels in tanks

using floater based level switches. A TSM can be used both for fresh and waste oil tanks.

The TSM (53430) is based on a TCM 53408 but has a lid (p/n 203 03 11) with a led indicator board (p/n 203 03 03)

and a connector adapter (p/n 203 03 17) added to the main board 203 02 91.

Earlier models than serial number 12-02000 can be made with either a MPDM (53400) with another software ( chip

labeled TSM 1.xx.xx) and/or have a lid with chassis mounted indicator led’s. Because of this a lot of this manual also

in most parts covers older modules. Some features may be missing and some default settings may be different.

NOTE!

The LUBE-Master installation manual should be available when installing and configuring a

TSM.

2. Mechanical installation

The TSM is delivered mounted in a metal box with power supply. It can also be delivered as a spare part PCB (p/n 203

03 91) .

Complete TSM in a box is mounted on a wall or other suitable place using the four-ø5 mm holes in the bottom corners

of the box.

If a PCB is used it is important that a power supply with enough performance is used, 24VBC 5A.

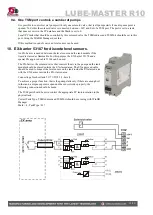

3. Electric installation

3.1. The main module

The TSM should be connected to mains 230VAC/50Hz using phase, neutral and ground.

Eurolube recommend that the connection is done through a 2-pole lockable working switch.

The “knock-out” holes on the lower right hand (see picture) should only be used for mains power supply to separate

mains from the circuit board (DC) side of the module.

The TSM is equipped with a switched power supply of 150W that can be set for 110VAC/60Hz or 230VAC/50Hz

by the internal switch shown by the yellow sticker.

It has five connectors

(A)

for the LUBE-Master communication. Two of these connectors,

MPDM IN

and

MPDM

OUT

are not connected to

+24V

and are intended for a connection to another TSM, MPDM or other modules that

already have +24VDC. This is to prevent conn24VDC from two power supplies.

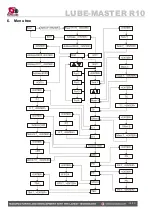

Содержание 53430

Страница 14: ...LUBE MASTER R10 14 21 6 Menu tree ...