Instruction Manual ZHK

96/129

V07-19.0

Spray humidifier

-

Fill pan and U-trap with fresh water and adjust float valve so that valve closes with a water level

2-3 cm below the overflow. Ensure in any case, bubble-free suck in.

-

Open the valves on the pump pressure side and suction side (where applicable) completely.

-

Check the tightness of all tube connections. Retighten the clamps using a torque wrench. Fix

the screw with a torque of 5….6,5 Nm.

-

Start the pump and re-check all tube connections for tightness. Repeat this check after 10

hours of operation.

-

When pump is running at nominal RPM, check the manometer on the pressure side. The water

pressure at the manometer should be 2.5….3.0 bar –

if necessary close pressure side valve

accordingly.

-

Check pump strainer, washer nozzles and tubes for proper fit.

-

Check humidifier strainer and clean it if necessary.

Evaporative humidifier

General indications:

-

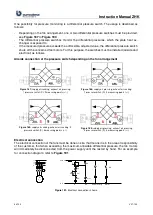

Check the proper installation of the PVC fins and droplet eliminator. The arrow must point in

direction of airflow (

-

Fins made from cellulose material can have initially an odor that is normal and will soon disap-

pear

.

Circulation water operation

-

The blowdown quantity is to be setup manually at the tacosetter.

Recommended setting (thumb): Bleed off rate = evaporation rate

-

Ensure that the pump impeller is completely covered by water. The water level must be regu-

lated by the maximum and minimum level switch.

-

Furthermore, it must be ensured by the control, that the designated conductivity, see

will not be exceeded. If the limit is reached, the blowdown valve must be opened.

High pressure spray humidifier

If no commissioning of the high pressure spray humidifier is agreed with EUROCLIMA, the manu-

facturer of the component must be contacted directly.

Steam Humidifier

The indications of the manufacturer of the steam humidifier must be observed for the commission-

ing.

Figure 193:

Installation of honey comb and droplet separator packages

Содержание ZHK Series

Страница 1: ...ZHK INSTRUCTION MANUAL ...