Instruction Manual ZHK

V07-19.0

99/129

SPB

RST 156

117

19

149

RST 164

125

19

157

RST 178

139

19

171

RST 187

148

19

180

RST 200

161

19

193

RST 250

211

19

243

Table 12:

Data of pulley types

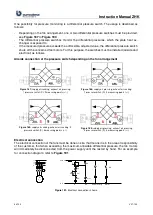

Changing the working diameter of a variable pulley:

1. Decrease the belt tension.

2. Open the over the disk circumference distributed screws (position see

3. Twist the outer ring (the outer rings for pulleys with 2 slots) to the desired diameter, observe

4. Fix the Allen screws.

5. Tighten the belts (refer to

chapter 9.2.4 (Re-tensioning of belts)

).

Figure 196:

Schematic structures of a

variable pulley

Figure 197:

Position of the Allen

screws on variable pullies

After a change of the transmission ratio, the current consumption of the motor must be controlled in

each case. If the consumption is too high, the effective diameter has to be adjusted again. The

nominal current shown on the nameplate must not be exceeded.

Determination of frequency converter caused problems

You can determine whether or not problems are caused by the frequency converter by connecting

the fan motor directly to mains power supply. Most commercially available frequency converters

have a feature to address these problems.

If the airflow is incorrect and if you require support on this matter, please contact EUROCLIMA.

8.3.2

Resonance at fans

The operation of fans at the resonant frequency (and multiples of it) must be avoided, in order to

prevent high vibration loads. The resonant frequency must be determined at the AHU on site.

shows a typical vibration curve.

Содержание ZHK Series

Страница 1: ...ZHK INSTRUCTION MANUAL ...