Information for installation

Pressure equalisation

25

recommended here. If damage to the boiler caused by

the introduction of oxygen is proven, all claims under

warranty and guarantee are void.

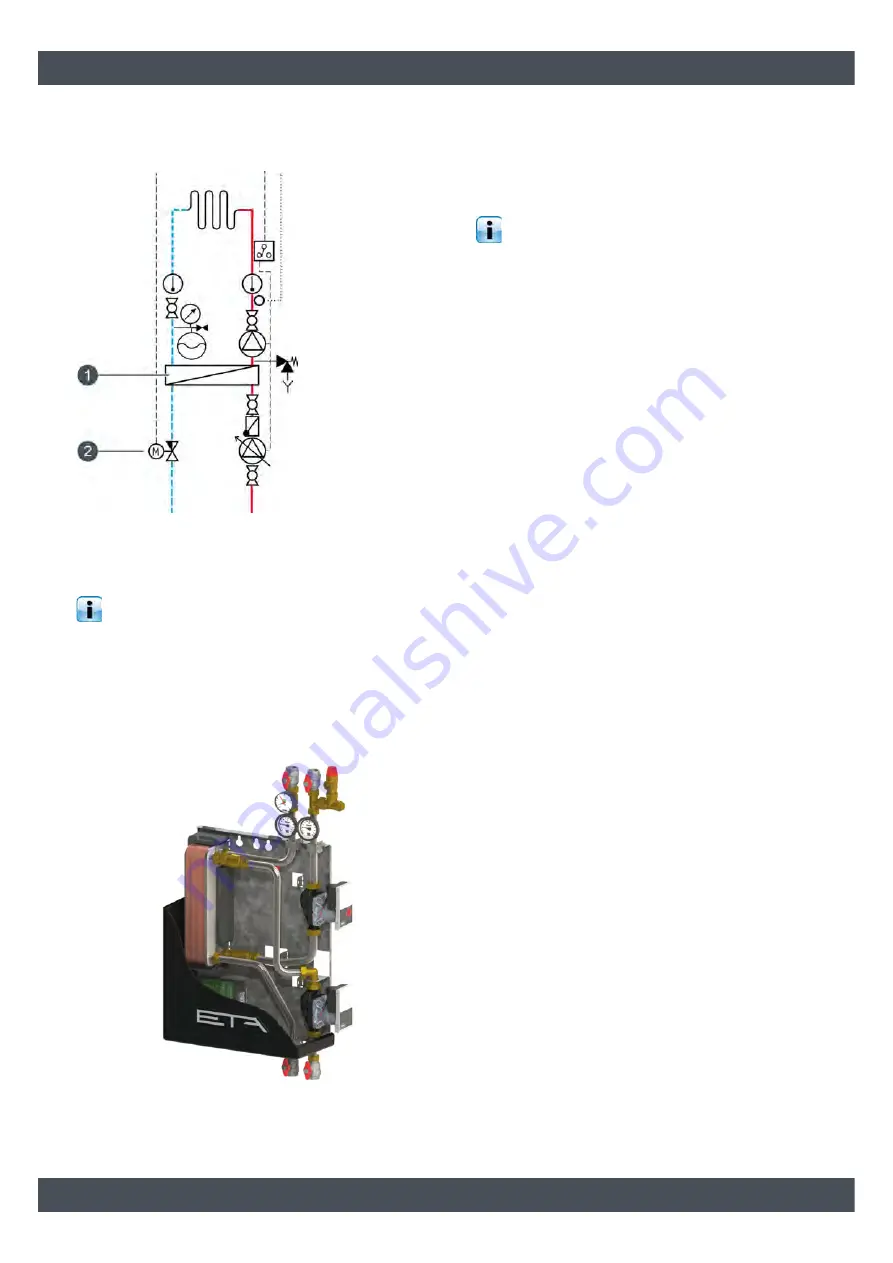

Fig. 7-6: System separation

1

Heat exchanger

2

Control valve

The hydraulically correct incorporation of the heat

transfer station (regardless of whether for system

separation or as a transfer station) must be adjusted

on the primary side. In order to achieve optimal flow

based on the flow temperature, the use of a two-way

control valve (see graphic above) is recommended.

Additionally, the primary pump should be designed

with differential pressure control. A system separation

module with these specifications is available from ETA.

Fig. 7-7: ETA system separation module

No open expansion tanks

Open expansion tanks improperly allow air into the

system. Existing systems with open expansion tanks

must be redesigned or physically separated from the

boiler.

Pressureless buffer storage may not be attached

directly to the boiler. If it is not possible to replace

this buffer, there must be a physical separation

between the boiler and the pressureless buffer.

7.6

Pressure equalisation

An expansion tank is needed

To equalise pressure in the system, a diaphragm

expansion tank with a gross capacity of around 10% of

the system volume is required. If the pressure

difference between cold and warm heating system

(buffer fully loaded if installed) is greater than 1.0 bar

for a single-storey system or 0.5 bar for a three-storey

system, then the expansion tank is too small and

absolutely must be replaced with a larger one. If the

installed expansion tank is not large enough, the

system sucks in air when cooling and the air is

absorbed by the cold water and transported to the

boiler. At the point of highest temperature, the air

separates from the water again. This usually takes

place in the boiler, and the inevitable result is that the

boiler wall will rust through in these spots.

Protect the expansion tank against shut-off

All shut-off valves along the path from the expansion

tank to the boiler and to the buffer storage tank must

be capped valves, or the hand wheels or levers must

be removed from the valves (hang on the valve with a

wire), to ensure that they cannot be closed inadver-

tently.

7.7

Noise emission

Airborne noise emission

In normal operation, the airborne noise emissions from

a pellet or wood chip boiler is between 40 and 50 dB(a)

with individual peaks of up to 75 dB(a) (ignition fan and

pellets vacuum motor).

To limit airborne noise emissions, the usual measures

that are required for all boiler rooms are sufficient:

•

Heavy doors such as the legally prescribed fire

doors

•

Restriction of the air intake openings to the

required minimum

•

Sound absorption insulation in the floors of the

rooms above

Содержание PelletsCompact PC33

Страница 1: ...2020 07 21 EN 0000000171 V 025 2707 93113 005 PelletsCompact 33 50 kW Installation...

Страница 33: ...Buffer storage tank Connection between multiple buffer storage tanks 33...

Страница 51: ...Installation Network connection 51...

Страница 55: ...Electrical connections Overview of circuit boards 55...

Страница 74: ...www eta co at...

Страница 75: ......

Страница 76: ...www eta co at www eta co at downloads DOWNLOAD...