Multi-part forms

It is best to use pressure-sensitive

multi-part forms.

The form sheets should be securely

joined together along the left and right

edges by crimping, spot-gluing, or tape

stitching. For the best printing quality,

use multi-part forms joined with

spot-gluing. Never use multi-part forms

joined with metalstaples.

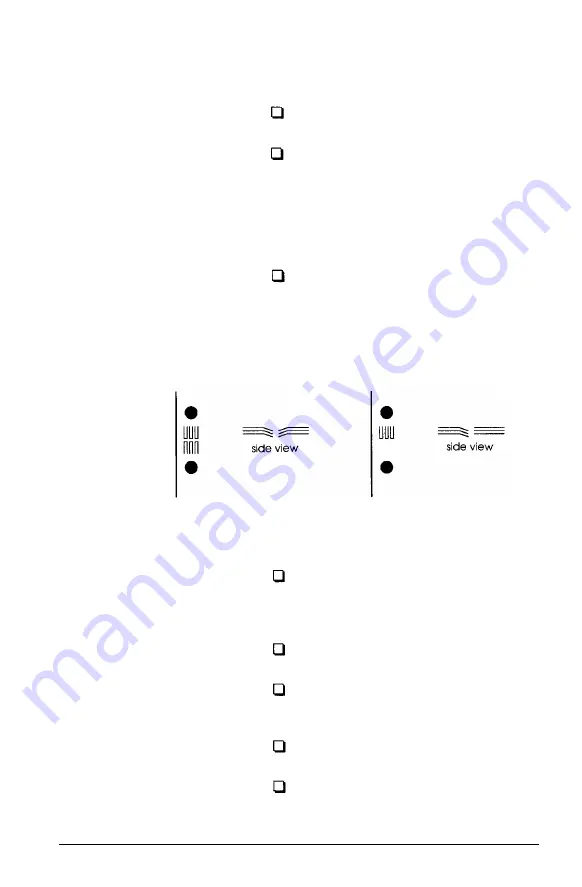

Crimping should be pressed in from the

original sheet side and go completely

through all copy sheets. Also, crimping

should be double-sided; using

single-sided crimping may cause the

printer to jam.

top view

double-sided crimping

top view

single-sided crimping

For multi-part forms joined with

spot-gluing, be sure the spots of glue are

spaced the same way on the left and

right edges of the paper.

The binding area should be flat and

have no creases.

Overlapping multi-part forms should be

joined together at the top of the pages

and not along the sides of the pages.

The sprocket holes of all sheets in the

form should be aligned properly.

The binding position should be outside

the printable area.

A-8 Technical Specifications

Содержание DFX-5000+

Страница 1: ......

Страница 2: ......

Страница 3: ......

Страница 6: ...Printer Parts ...

Страница 156: ...PC437 USA standard Europe PC850 Multilingual PC860 Portuguese Printer Commands and Character Tables B 15 ...

Страница 159: ...PC853 Turkish PC857 Turkish ISO Latin 1T Turkish PC855 Cyrillic B 18 Printer Commands and Character Tables ...

Страница 160: ...PC866 Russian PC852 East Europe MAZOWIA Poland Code MJK CSFR Printer Commands and Character Tables B 19 ...

Страница 163: ...PC437 table 1 PC437 table 2 B 22 Printer Commands and Character Tables ...