ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt

21

After completing all the operations, the system is ready for submission to the leak test and the whole refrigerant

fluid loading process.

5.3.6.

Leak test

A nitrogen load at a pressure of

10 bar (Max)

would be ideal to ensure that there are no leaks on the welds carried

out. Once the installation is loaded, cover all the welds in soapy water and check that there are no nitrogen leaks.

The panels must remain 2 to 3 days with the nitrogen load so as to ensure that there is no leak. Once this operation

has been completed, remove all the nitrogen from the installation.

5.3.7.

Vacuum

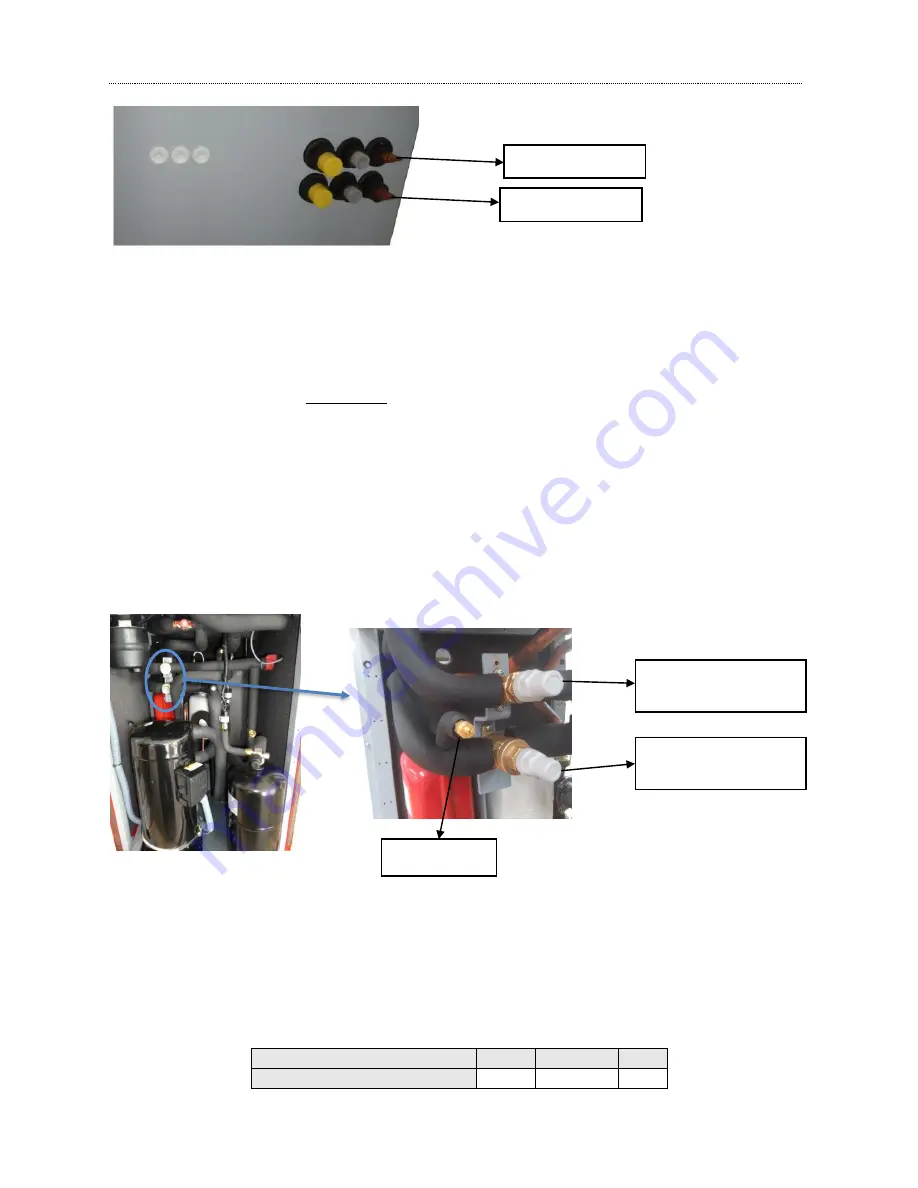

This operation is carried out using one load pipe, that is located inside of the unit, at the aspiration pipe. During this

operation, the two hermetic valves should be closed as factory instalation.

Before loading the refrigerant fluid, it is vital to carry out a vacuum at the installation. The purpose of the vacuum is

to remove all the air and humidity to be found on the circuit. The vacuum time depends on the following factors:

✓

Volume in m

3

/h of the vacuum pump.

✓

Volume of the system piping.

On average, the minimum vacuum time to be carried out at an installation, depending on the system installed, is

shown in the table below.

Combi

6

12 / 12 HT

16

Minimum vacuum time (hours)

3

6

7

Liquid Pipe

Load Pipe

Aspiration Pipe

Aspiration Hermetic

Valve

Liquid Hermetic

Valve

Содержание Combi 12

Страница 29: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT www energie pt 29 8 2 Combi System 400 420 Vac 3 N 50 Hz...

Страница 31: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT www energie pt 31 9 ANNEXES B INSTALLATION 9 1 Plan...

Страница 34: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT 34 www energie pt...