ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

20

www.energie.pt

5.3.5.

Implementation of piping connections (Welds)

Once the Panels are installed and the Combi Block has been finally placed at the site, now the following types of

piping must be placed:

✓

Liquid (Outward to panels).

✓

Aspiration (Return from panels).

Before making the aforementioned connections, it is best to carry out the connections of the panel tubes to the:

✓

Liquid distributor (s).

✓

Aspiration collector (s)

The implementation of the connections is one of the most delicate points of the whole installation and it is extremely

important that the welds are carried out in line with all the basic criteria of a quality welding process.

The recommended welding type for implementing the piping connection is oxy-acetylene welding

(oxygen/acetylene). Other types of gas may also be used such as propane, for example.

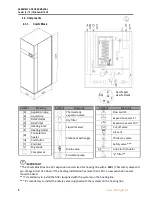

The most delicate welds and which require the greatest care are carried out at the panels. It is necessary to place

a damp fabric strip which must envelop the “Thermoretractable Joint” so that it is f

uly protected from high

temperatures caused by the blowlamp flame as shown in the figure below.

The copper is heated until it goes dark red at which point welding must begin. Bring the slightly inclined welding rod

closer without exposing it to the flame. As a general rule, the quantity to be applied is the same as one and a half

times the tube diameter. As soon as the alloy expands, stop heating and let it cool.

As soon as the weld is in a solid state, you must cool the whole area around the weld immediately with a damp

cloth.

Welds alongside the Combi Block must also be carried out with due care so as not to burn any component of the

Combi Block.

You should weld the aspiration and the liquid pipe to the corresponding pipping, at the back of the Combi Block. Be

carefull with the welding process.

Key:

A

Thermoretractable Joint

B

Connection and Weld

C

Aspiration Line (panel outlet)

D

Liquid Line (panel inlet)

Содержание Combi 12

Страница 29: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT www energie pt 29 8 2 Combi System 400 420 Vac 3 N 50 Hz...

Страница 31: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT www energie pt 31 9 ANNEXES B INSTALLATION 9 1 Plan...

Страница 34: ...ASSEMBLY AND USER MANUAL Combi 6 12 16 Combi 12 HT 34 www energie pt...