Technical Manual Cold Storage Controller EVP 3150-1 and EVP 3150-2

Page 16

Installation / Start-Up

Upon applying voltage to the controller, after a few seconds the display

shows the parameter which is selected as permanent display or an actual

error code.

Start-up sequence

• Assign inputs/outputs to functions (see example on page 3)

• Select type of used temperature sensors ("

P35

", Mode Page),

use TF 501 types for EEx-valves.

• Correct the displayed temperature values if necessary

("

P31

"-"

P34

", Mode Page).

• Set date and time ("

P81

"-"

P87

", Mode Page)

• Set defrost mode ("

d02

", Defrost Page)

• Set fan mode "

d01

" and "

P02

"

• Set cooling mode "

P03

" (Mode Page)

• See page 9 for parameterization of the pressure transmitter inputs

These are the most important steps for the basic configuration of the controller.

Upon that, adapt the other parameters like temperature setpoint, hysteresis,

delay times.... Refer to the previous chapters in this manual.

Start-up in a data network

• Set the address of the controller ("

P90

", Mode Page)

• Upload parameters from PC to controller

The EVP offers several status messages, which enables you to check the

states of inputs and outputs:

• "

L50

", value of the analogue output

• "

L60

", state of the digital inputs DI1 and DI2

• "

L61

", state of the relays

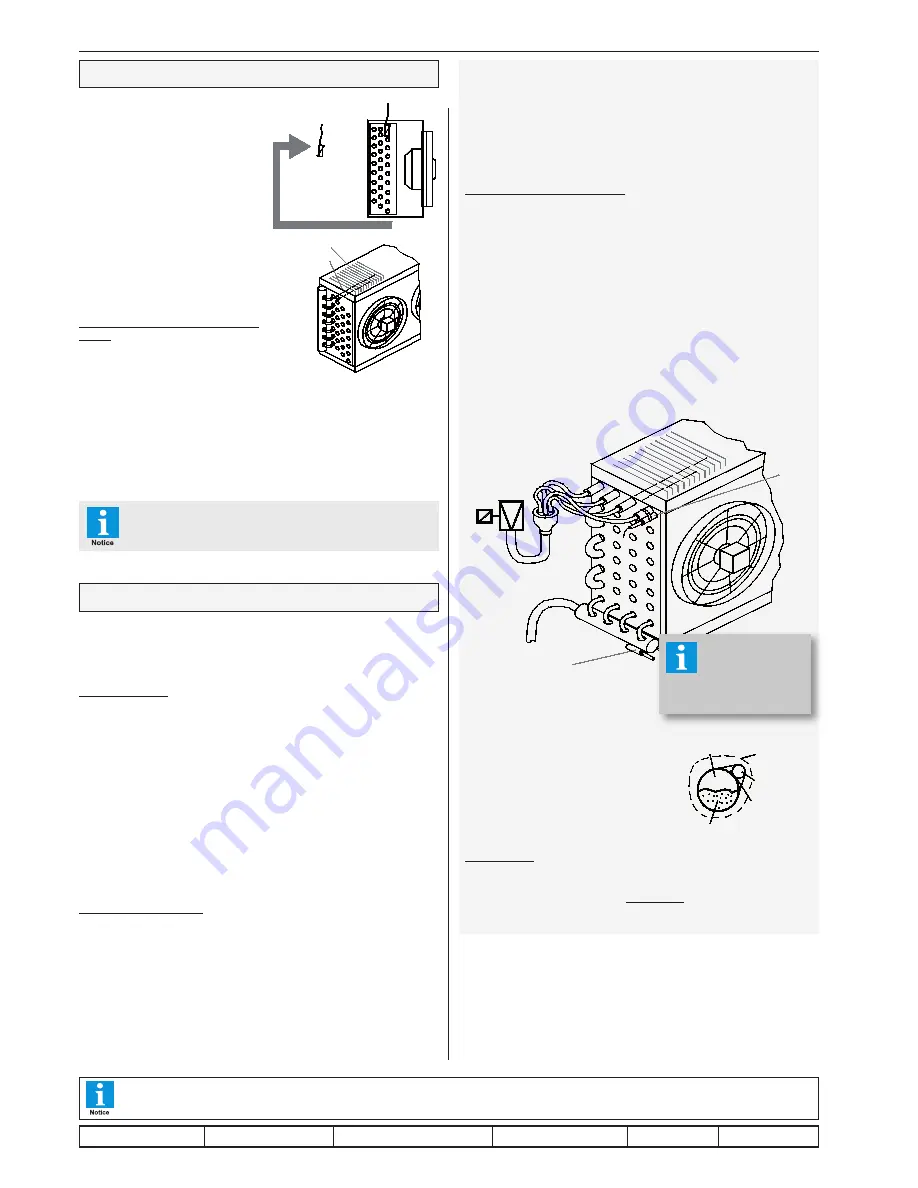

Sensor positions for EEx-Valve Control,

Pressure Transmitter / Temperature Sensor Method

The pressure transmitter must be mounted at the suction pipe, at a position

where no pressure decrease can affect the measuring. The best place is

close to the evaporator. If there are several evaporators, select a position

from where the distance to all evaporators is as short as possible.

Selection of Pressure Transmitter

To detect a pressure transmitter malfunction, the signal voltage input is

scalable. So you can use e.g. transmitters with an 2...10V output which

makes it easier to recognize a malfunction.

Number of controllers working with the same pressure

transmitter

The input resistance of the pressure transmitter input is 80 kOhm. Several

inputs can be connected in parallel, but the resulting resistance must not

fall below the minimum specifications of the used pressure transmitter.

In practise, up to 10 controllers mostly work trouble-free.

Sensor positions for EEx-Valve control,

Temperature Sensors Method

*

= alternative positions for Outlet-Sensor

Please care for a good isolation

by foamed material, so that none

of the sensors get contact with

the airflow.

Pipe mounting

Most expedient is it to use

cable fixers

, some thermal conduction silico-

ne cares for a good thermal flow.

Metallic fixers with high mass are not qualified.

Sensor Positions

Sensor positions are not critical in stan-

dard applications. The

control sensor

or

alarm sensor

has to be fixed behind

the evaporator (air-inlet) or at a repre-

sentative place in the chamber, but not

in the air outlet.

The second sensor (

defrost term-inati-

on sensor, evaporator sensor

) should

be assembled in the contact pipe or

within the fins of the evaporator. A good

thermal exchange to the fins is important.

It should be placed at the position where

the ice remains the longest time while

a defrost cycle.

Sensors for intelligent (adaptive)

defrost

To detect icing the EVP doesn't need

additional sensors. The control sensor

and the defrost (evap.) sensor are suf-

ficient. Please note that the emergency

defrost mode is not able to prevent ice-

clusters or slow glacieration in case of a

incorrect sensor position. If ice-clusters

appear, the defrost sensor must be

placed at this position.

After start-up, Please check the position of the

evaporator sensors accurately!!

This manual, which is part of the product, has been set up with care and our best knowledge, but mistakes are still possible. Technical details

can be changed without notice, especially the software. Please note that the described functions are only valid for units containing the software

with the version-number shown on page 1 of this manual. Units with an other version number may work a little bit different.

evap sensor

control sensor

airflow

fins

contact-

pipe

*

*

*

pipe

distributor

EEx-valve

outlet

sensor

inlet

sensor

foam Isolation

sensor

thermal

conduction

silicone

liquid

gaseous

refrigerant in evaporator pipe

For more infor-

mation about

Electronic Ex-

pansion Valves

see page 9 !

set up: 26.6.17, tkd/jr

checked: 26.6.17, ek/jk approved: 26.6.17, mv/sha

transl.(E): ...................... transl()................ corr.