Guide to diagnostics of electronic controls EWM10931

2011 SOE/DT-mdm FCPD-dp Quality-tb

38/75

599 73 77-37

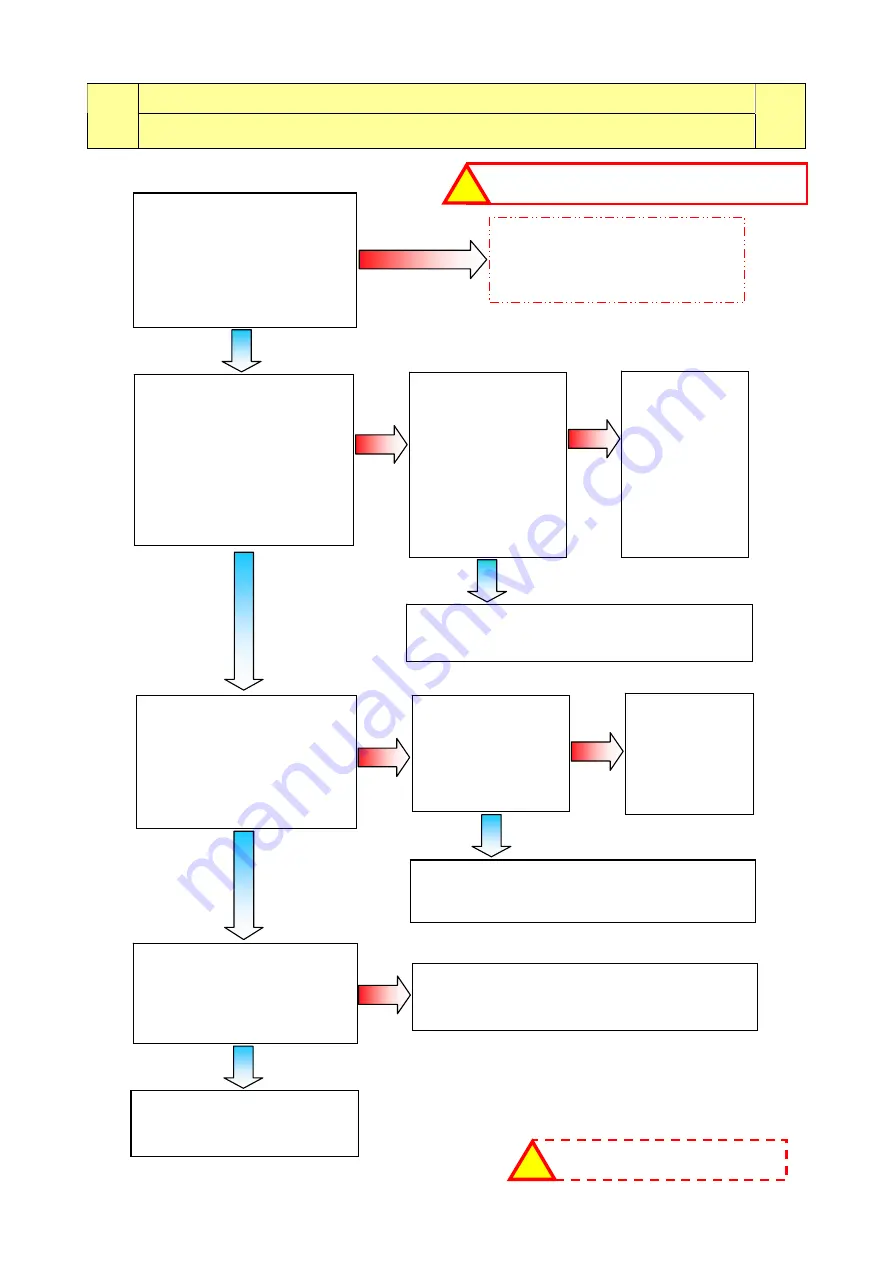

E52: No signal from motor tachometric generator

(first part)

E52

Cycle interrupted

after 5 attempts during the cycle, immediately if recognised

at the start of the cycle or during diagnostics.

E52

Checks to perform:

Access

phase 8

of the diagnostic cycle

(The drum rotates at 55 rpm

clockwise 55 rpm

anticlockwise with pulse at

250 rpm). Is the motor

running correctly?

Check/replace the wiring and repeat

the diagnostic cycle to check for any

further alarms.

Replace the

motor or

tachometric

generator and

repeat the

diagnostic

cycle to check

for any

further alarms.

Measure between the same

terminals of the wiring

connector

(J2-3 and J2-4) and the

appliance body.

Is there any dispersion?

-(see fig.13)-

Check the

positioning of the

tachometric

generator.

Is it correct?

-(see fig.12)-

Replace the motor control board and repeat

the diagnostic cycle to check for any

further alarms.

Replace the

motor/generator

and repeat

the diagnostic

cycle to check

for any

further alarms.

Check/replace the wiring and repeat

the diagnostic cycle to check for any

further alarms.

The motor never runs

-see page 39-

Measure between the

terminals of the wiring

connector

J2-3 and J2-4.

Are the values (

Ω

) of

the tachometric

generator correct?

(as on

page 41

- Point 4 - phase “A”).

Detach the

connector from the

motor and measure

(

Ω

) the tachometric

generator coil

-(see fig.11)-

Is the value

correct?

(as on

page 41

Point 4 - phase “A”).

Replace the motor and repeat

the diagnostic cycle to check

for any further alarms.

Detach the connector from

the motor and measure

between the terminals and the

motor casing.

-(see fig.10)-

Is there any dispersion?

NO

Y

E

S

Check that all the connectors are correctly inserted

!

If there are burns on the circuit

board, see page 73

!

NO

NO

Y

E

S

Y

E

S

NO

NO

NO

Y

E

S

Y

E

S

Y

E

S