16

6 - COMBUSTION AIR AND VENT PIPING- CATEGORY I (CHIMNEY VENT)

6.4

Modulating Fan

• Unit is equipped with an advanced combustion air, vent

fl

ow control system, with modulating fan and pressure

sensor.

• Unit automatically adapts its operation to

fl

ue type

and length, without requiring adjustments during

installation or use of baf

fl

es in combustion circuit.

• Unit consistantly and automatically regulates

combustion air and vent

fl

ow according to change in

thermal load. Combustion and heat exchange occur in

optimum conditions. Unit’s thermal ef

fi

ciency remains

high throughout its power range.

6.5

Venting Materials

• See Table 3

6.2 Minimum Vent Pipe Clearance

• Use Type B vent pipe through crawl space. Where vent

pipe passes through combustible wall or partition, use

ventilated metal thimble. Thimble should be 4 inches

larger in diameter than vent pipe.

• Boiler installed with single wall vent, must have 6”

clearance between its surface and any combustible

material. New Type B gas vent or

fl

exible liner must be

installed in accordance with instructions furnished with

vent. Maintain clearances as speci

fi

ed for vent pipe.

• Verify vent pipe is

fi

re-stopped where it goes through

fl

oor or ceiling. It should have approved vent cap with

clearances from roof. If clearances are less than shown,

have vent checked by local authorities. Figure 13, Page

20.

• Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of

mechanical draft systems operating under positive

pressure.

6.3 Removing Existing Boiler From Common

Venting System

When an existing boiler is removed from a common

venting system, common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it.

1.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliance

remaining connected to the common venting system

are not in operation.

2.

Seal any unused openings in the common venting

system.

3.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other de

fi

ciencies

which could cause an unsafe condition.

4.

Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close

fi

replace dampers.

5.

Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

6.

Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use

fl

ame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

7.

After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans,

fi

replace dampers and

any other gas-burning appliance to their previous

conditions of use.

8.

Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1. When re-sizing any portion of the

common venting system, the common venting system

should be re-sized to approach the minimum size

determined using the appropriate tables in Chapter 13

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1.

9.

It is recommended that existing gas vents be checked

to be sure they meet local codes.

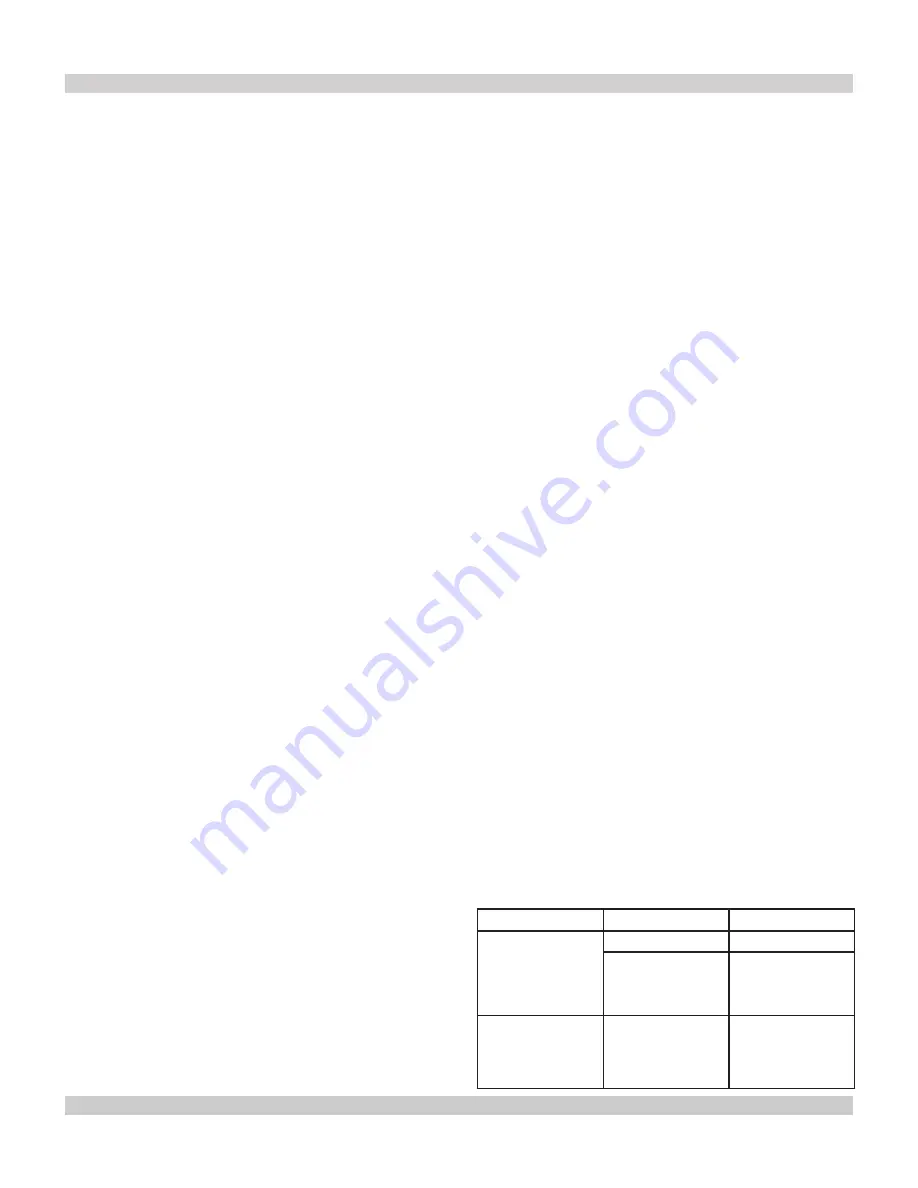

Item

Material

Standards

Vent Pipe & Fittings

Type B Vent

UL 441, ULC S605

Masonry Chimney

- must conform to

proper sizing and

materials

National Fuel

Gas Code, ANSI

Z223.1/NFPA 54

Combustion Air

Stainelss Steel,

PVC, CPVC, PP,

Aluminum

ANSI/ASTM

D2564, ANSI/

ASTM F493, UL

1738/ULC636-08

Table 3 - Combustion Air and Vent Pipe Fittings

Category I (Chimney Vent)

Содержание CHB-100

Страница 6: ...Figure 2 Component Listing 6 3 GENERAL VIEW AND MAIN COMPONENTS ...

Страница 33: ...33 12 RATINGS AND CAPACITIES ...

Страница 38: ...KEY Part Number Description Qty A01 FE3980B830 CASING CTR 1 38 REPAIR PARTS LIST CHB 100 ...

Страница 40: ...40 REPAIR PARTS LIST CHB 100 ...

Страница 42: ...42 REPAIR PARTS LIST CHB 100 ...

Страница 44: ...KEY Part Number Description Qty A01 FE3980B830 CASING CTR 1 44 REPAIR PARTS LIST CHB 130 ...

Страница 46: ...46 REPAIR PARTS LIST CHB 130 ...

Страница 48: ...48 REPAIR PARTS LIST CHB 130 ...

Страница 50: ...NOTES 50 ...

Страница 51: ...NOTES 51 ...

Страница 52: ...ECR International Inc 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...