16

EN

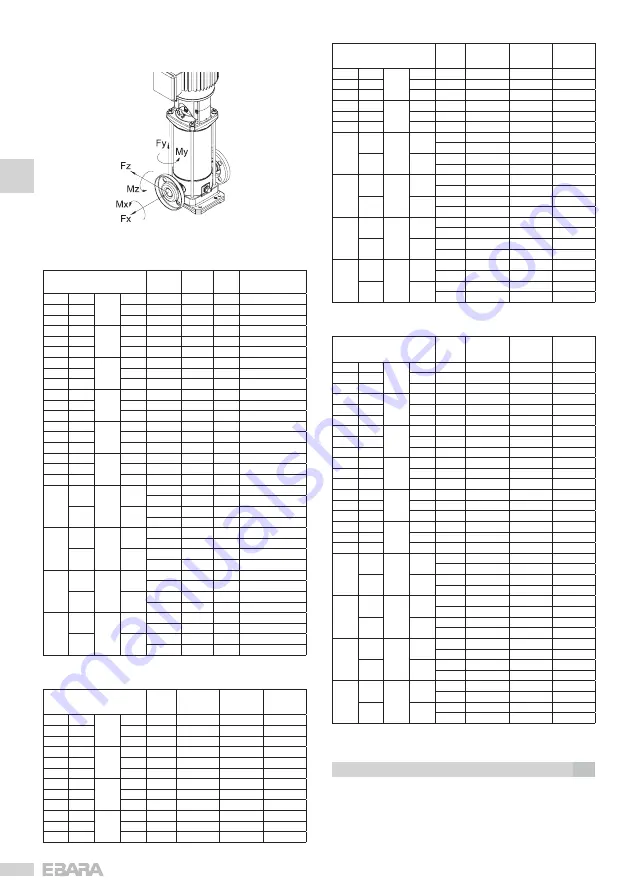

8.3 FLANGE LOADING AND TIGHTENING TORQUES

Flange tightening torques

Model

Flange

DN

Bolt

n°

Bolt Tightening torque [Nm]

EVMS (L)(G)

1

N

25

M10

2

30

EVMS (L)(G)

F

25

M12

4

50

EVMS (L)(G)

LF

25

M12

4

50

EVMS (L)(G)

3

N

25

M10

2

30

EVMS (L)(G)

F

25

M12

4

50

EVMS (L)(G)

LF

25

M12

4

50

EVMS (L)(G)

5

N

32

M10

2

30

EVMS (L)(G)

F

32

M16

4

70

EVMS (L)(G)

LF

32

M16

4

70

EVMS (L)(G)

10

N

40

M12

2

50

EVMS (L)(G)

F

40

M16

4

70

EVMS (L)(G)

LF

40

M16

4

70

EVMS (L)(G)

15

N

50

M12

2

50

EVMS (L)(G)

F

50

M16

4

70

EVMS (L)(G)

LF

50

M16

4

70

EVMS (L)(G)

20

N

50

M12

2

50

EVMS (L)(G)

F

50

M16

4

70

EVMS (L)(G)

LF

50

M16

4

70

EVMS

(L)

32

LF

65

M16

4

80

65

M16

8

80

(G)

F

65

M16

4

80

65

M16

8

80

EVMS

(L)

45

LF

80

M16

8

80

80

M16

8

80

(G)

F

80

M16

8

80

80

M16

8

80

EVMS

(L)

64

LF

100

M16

8

80

100

M20

8

100

(G)

F

100

M16

8

80

100

M20

8

100

EVMS

(L)

90

LF

100

M16

8

80

100

M20

8

100

(G)

F

100

M16

8

80

100

M20

8

100

Admissible strain on the flange

Model

Flange

DN

Strain X

[N]

Strain Y

[N]

Strain Z

[N]

EVMS (L)(G)

1

N

25

230

200

180

EVMS (L)(G)

F

25

230

200

180

EVMS (L)(G)

LF

25

230

200

180

EVMS (L)(G)

3

N

25

230

200

180

EVMS (L)(G)

F

25

230

200

180

EVMS (L)(G)

LF

25

230

200

180

EVMS (L)(G)

5

N

32

270

230

210

EVMS (L)(G)

F

32

270

230

210

EVMS (L)(G)

LF

32

270

230

210

EVMS (L)(G)

10

N

40

370

330

300

EVMS (L)(G)

F

40

370

330

300

EVMS (L)(G)

LF

40

370

330

300

Model

Flange

DN

Strain X

[N]

Strain Y

[N]

Strain Z

[N]

EVMS (L)(G)

15

N

50

490

450

400

EVMS (L)(G)

F

50

490

450

400

EVMS (L)(G)

LF

50

490

450

400

EVMS (L)(G)

20

N

50

490

450

400

EVMS (L)(G)

F

50

490

450

400

EVMS (L)(G)

LF

50

490

450

400

EVMS

(L)

32

LF

65

2100

1850

1700

65

2100

1850

1700

(G)

F

65

1050

925

850

65

1050

925

850

EVMS

(L)

45

LF

80

2500

2250

2050

80

2500

2250

2050

(G)

F

80

1250

1125

1025

80

1250

1125

1025

EVMS

(L)

64

LF

100

3350

3000

2700

100

3350

3000

2700

(G)

F

100

1675

1500

1350

100

1675

1500

1350

EVMS

(L)

90

LF

100

3350

3000

2700

100

3350

3000

2700

(G)

F

100

1675

1500

1350

100

1675

1500

1350

Admissible torque on the flange

Model

Flange

DN

Torque X

[Nm]

Torque Y

[Nm]

Torque Z

[Nm]

EVMS (L)(G)

1

N

25

190

240

160

EVMS (L)(G)

F

25

190

240

160

EVMS (L)(G)

LF

25

190

240

160

EVMS (L)(G)

3

N

25

190

240

160

EVMS (L)(G)

F

25

190

240

160

EVMS (L)(G)

LF

25

190

240

160

EVMS (L)(G)

5

N

32

230

280

190

EVMS (L)(G)

F

32

230

280

190

EVMS (L)(G)

LF

32

230

280

190

EVMS (L)(G)

10

N

40

310

390

270

EVMS (L)(G)

F

40

310

390

270

EVMS (L)(G)

LF

40

310

390

270

EVMS (L)(G)

15

N

50

340

420

300

EVMS (L)(G)

F

50

340

420

300

EVMS (L)(G)

LF

50

340

420

300

EVMS (L)(G)

20

N

50

340

420

300

EVMS (L)(G)

F

50

340

420

300

EVMS (L)(G)

LF

50

340

420

300

EVMS

(L)

32

LF

65

1200

1500

1100

65

1200

1500

1100

(G)

F

65

600

750

550

65

600

750

550

EVMS

(L)

45

LF

80

1300

1600

1150

80

1300

1600

1150

(G)

F

80

650

800

575

80

650

800

575

EVMS

(L)

64

LF

100

1450

1750

1250

100

1450

1750

1250

(G)

F

100

725

875

625

100

725

875

625

EVMS

(L)

90

LF

100

1450

1750

1250

100

1450

1750

1250

(G)

F

100

725

875

625

100

725

875

625

9. ELECTRICAL CONNECTION

− ELECTRICAL CONNECTION MUST BE CARRIED OUT BY A QUALIFIED

ENGINEER.

− IT IS ADVISABLE TO INSTALL A HIGH INTENSITY DIFFERENTIAL

SWITCH (0.03 A) ON BOTH THE THREEPHASE AND SINGLE PHASE

VERSIONS.

[-B-]

Содержание EVMS 1

Страница 85: ...85 12 13 14 9 8 10 11 A EVMS 1 3 5 10 15 20 3 Nm...

Страница 87: ...87 A EVMS 32 45 64 90 without ball bearing 9 10 11 12 13 14 15 5 Nm 2 min...

Страница 88: ...88 A EVMS 32 45 64 90 with ball bearing 2 min 1 2 3 4 5 7 6 M8 20 Nm M12 40 Nm M16 70 Nm...

Страница 91: ...91 E EVMS 1 3 5 10 15 20 4 kW 1 2 3 4 5 6 7 8 9 10 3 Nm M6 10 Nm 11 12...

Страница 92: ...92 E EVMS 1 3 5 10 15 20 5 5 kW 1 2 3 4 5 6 7 8 9 10 11 12 3 Nm M8 18 Nm M10 50 Nm...

Страница 97: ...97...

Страница 98: ...98...

Страница 99: ...99...