8

© 2022 Eaton Cummins Automated Transmission Technologies. All rights reserved

2022.10.7

Timing Procedures

|

General Information

TRSM0940

Timing Procedures

It is essential that both Counter Shaft assemblies of the

front and auxiliary sections are timed. This ensures proper

tooth contact is made between Main Shaft gears seeking to

center on the Main Shaft during torque transfer and mating

Counter Shaft gears that distribute the load evenly. If not

properly timed, serious damage to the transmission is likely

to result from unequal tooth contact, causing the Main

Shaft gears to climb out of equilibrium.

Timing is a simple procedure of marking the appropriate

teeth of a gear set prior to installation and placing them in

proper mesh while in the transmission. In the front section,

it is necessary to time only the drive gear set. Depending on

the model, only the low range, deep reduction or splitter

gear set is timed in the auxiliary section.

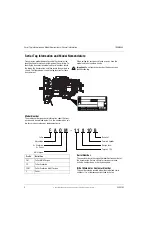

Front Section

1. Clearly mark the tooth located directly over the

drive gear keyway as shown prior to placing each

Counter Shaft assembly into the case, This tooth is

stamped with an “O” to aid identification.

2. Mark any two adjacent teeth on the Main Drive

Gear.

3. Mark the two adjacent teeth located directly oppo-

site the first set marked on the Main Drive Gear.

There should be an equal number of unmarked

gear teeth on each side between the marked sets.

4. After placing the Main Shaft assembly into the

case, the Counter Shaft Bearings are installed to

complete installation of the Counter Shaft assem-

blies. This meshes marked Counter Shaft drive gear

teeth with marked Main Drive Gear teeth.

When installing the bearings on the left Counter Shaft,

mesh the Counter Shaft drive gear marked tooth with either

set of Main Drive Gear two marked teeth.

Repeat the procedure when installing the bearings on the

right Counter Shaft; make use of the remaining set of Main

Drive Gear two marked teeth to time the assembly.

Содержание UltraShift PLUS

Страница 265: ......