I.B. 48003

Page 18

Effective 11/97

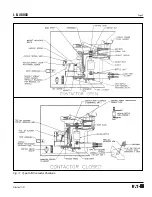

CONTACTOR MAINTENANCE (Continued)

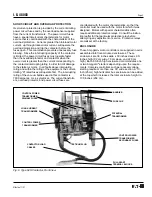

Contact Wear Allowance

Contact material vaporizes from the contact faces during

every interruption and condenses elsewhere inside the

bottle. This is normal, and is provided for by overtravel,

or wear allowance. When the contactor is fully closed,

there is a gap between the lower bottle nut and a pivot

plate. See Figure 12. As the contacts wear, this gap

decreases. When the gap goes below .020 inch (.51

mm) on any pole, all the bottle subassemblies should be

replaced. Use the .020-inch (.51-mm) thick fork-shaped

overtravel feeler gauge supplied for this measurement,

part no. 5259C11. DO NOT RE-ADJUST THE BOTTLE

NUTS TO RESET OVERTRAVEL AS THE CONTACTS

WEAR. Once placed into service, overtravel should be

checked but not adjusted.

Inspection After Short Circuit Or Overload

The Type SJD contactor is intended to be protected by

power circuit fuses in accordance with the NEC. How-

ever, the magnitude of a short circuit may exceed the

damage threshold of the vacuum bottles. After the

interruption of any short circuit, particularly after a major

one that might have been near the maximum MVA rating

of the controller, examine the unit for any apparent

physical damage, or deformation of conductor bars and

cables. If there is any evidence of severe stress, all

bottle subassemblies must be replaced. If the overtravel

has changed significantly (from the last inspection) on

one or more bottles, replace all bottle subassemblies.

A dielectric test does not by itself confirm that the bottles

should be returned to service after a fault. However, if

there is no physical evidence of stress, and if the

overtravel exceeds the .020-inch (.51-mm) minimum, the

bottles can then be dielectrically tested as outlined

previously. If physical stress, overtravel, and dielectric

test results are within acceptable limits, it is reasonable to

return the contactor to service after a fault.

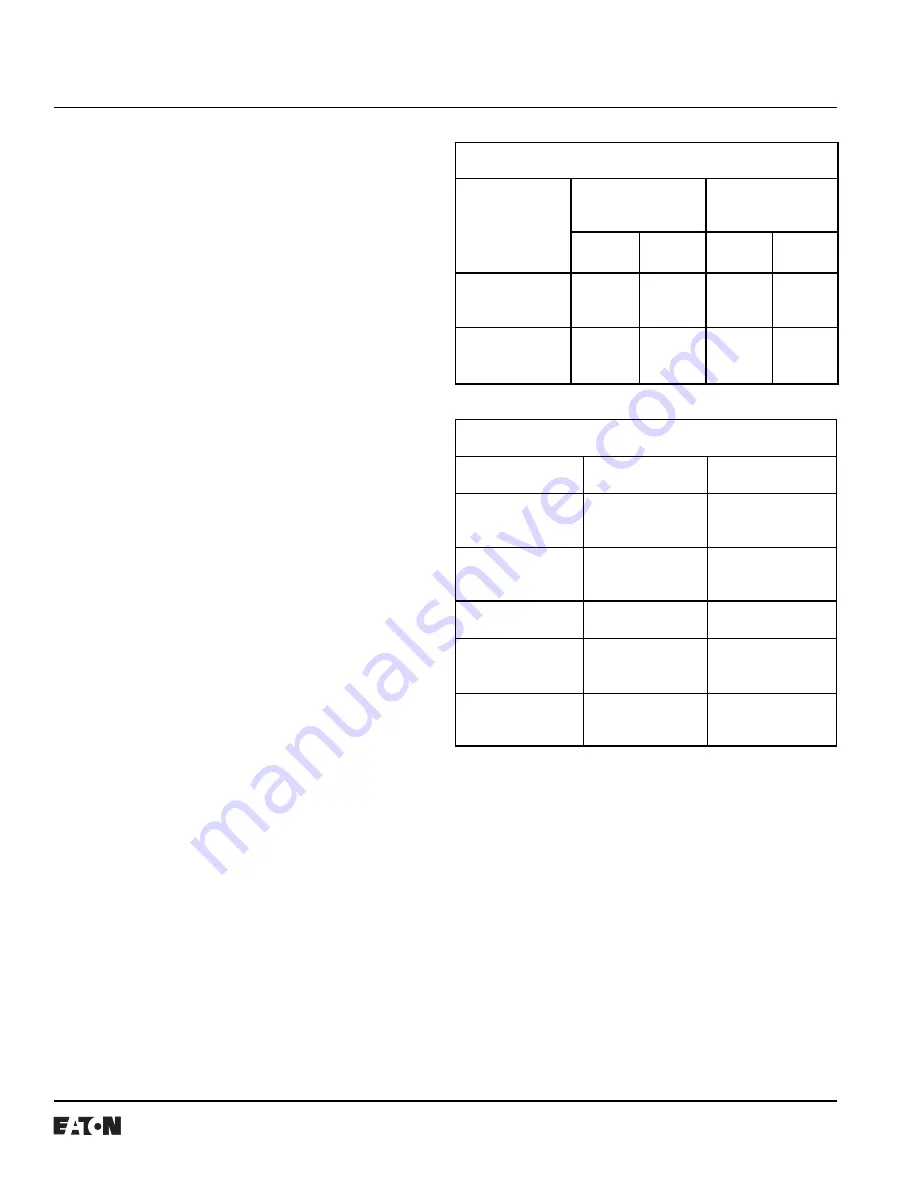

Magnet Operating Range

When properly adjusted as described in previous sec-

tions, the contactor should operate within the ranges

shown in Table II.

Operating Coil

The standard operating coils are shown in Table III. They

should be supplied directly from an AC or DC source with

sufficient volt-ampere capacity to maintain coil voltage

during inrush while closing. No external resistors are

required.

Changing Operating Coil

The contactor operating coil has a pick-up winding which

is intermittently rated. It may burn out in only minutes if

continuously energized at rated voltage and the L63

auxiliary contact does not open correctly.

The coil contains its own rectifier to convert applied AC

into unfiltered full-wave rectified DC. When parts are in

alignment and the coil is at rated voltage, the magnet will

be silent. At reduced voltage, a slight hum is acceptable.

However, the magnet must not chatter.

TABLE II. COIL PERFORMANCE

Rated

Coil

Voltage

Pick-Up-To-Seal

Voltage

Drop-Out-To-

Full-Open

Voltage

Above

Below

Below

Above

110-120 VAC

50

96

75

10

125 VDC

55

100

82

11

220-240 VAC

100

192

150

20

250 VDC

110

200

164

22

TABLE III. OPERATING COILS

Coil Part No.

7860A34G02

7860A34G04

AC Rating

110-120 VAC

220-240 VAC

50-60Hz

50-60Hz

AC Inrush

1300 VA

1400 VA

AC Sealed

25 VA

26 VA

DC Rating

125 VDC

250 VDC

DC Inrush

1500 VA

1600 VA

DC Sealed

28 VA

29 VA

Replacement

2147A48G11

2147A48G21

Coil Kit Part No.

Содержание Cutler-Hammer Ampgard SC9000

Страница 3: ...I B 48003 Page 3 Effective 11 97 Fig 4 Ampgard Components Two Starters Controllers Shown ...

Страница 9: ...I B 48003 Page 9 Effective 11 97 Fig 11 Type SJS Contactor Positions ...

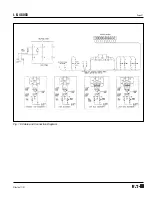

Страница 21: ...I B 48003 Page 21 Effective 11 97 Fig 16 Cable and Connection Diagram ...

Страница 24: ...I B 48003 Page 24 Effective 11 97 Printed in U S A CCI Cutler Hammer 221 Heywood Road Arden NC 28704 ...