54

Form E-551

Scheduled Maintenance Procedure

CAUTION

It is important to perform regular maintenance on the equipment. A daily, weekly and monthly schedule should be

maintained. Failure to do so can result in more frequent breakdowns damage to equipment and/or injury.

Proper Maintenance will help to ensure the reliable operation of your Multi-Ply cutter. You should allow 5 to 10 minutes for

daily inspection, 30 minute weekly inspection and one hour monthly inspection. Time invested on these tasks will mini-

mize downtime. Eastman Machine Company is not liable for damage as a result of poor maintenance and any resulting

damage would be repaired at user’s expense. All maintenance should be performed by qualified personnel, following all

safety procedures. The following is the recommended maintenance schedule:

Daily Maintenance

•

At the start of each shift, carefully inspect the machine and cutting surface. Look for any debris, loose

cables or any other obstruction that may interfere with machine movement or cutting. Vacuum bristle

surface as required to remove dust and dirt which may clog perforations.

•

After the Multi-Ply cutter is powered up, check both the X and Y axes for backlash. If the backlash is

excessive on either axis, adjust as required.

•

Check connecting link to verify that it is securely fastened to reciprocating assembly. Check blade edges

for nicks and replace as required. Ensure that the knife is securely fastened to the coupler.

•

At the end of each work session make sure the computer is off. Clean-up debris from table and remove

any CD or Disks from the disk drives.

•

At the end of the day disconnect power to the machine.

•

At the end of the day press the spring loaded presser foot of the sharpening assembly and using dry

compressed air blow of any loose dust and debris found on the knife guide assemblies and within the

sharpening housing. Using soft bristle brush clean all accessible surfaces and knife guide assemblies.

Again blow of any loose dust and debris found after cleaning with bristle brush.

Weekly or every 40 hours

CAUTION

Before performing the weekly tasks make sure the Multi-Ply cutter and computer are turned off at the electrical

disconnect and locked out.

•

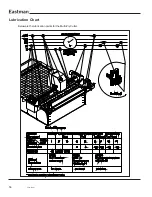

Lubricate table rail linear bearing with Eastman lubricant 67-26325 (Mobil: SEA 10 Non-detergent Vactra

No. 1) See Lubrication Chart.

•

Lubricate gantry rail linear bearing with Eastman lubricant 67-26325 (Mobil: SEA 10 Non-detergent Vactra

No. 1) See Lubrication Chart.

Содержание MPC 5000

Страница 25: ...25 FormE 551 8 Remove the screws found on the non operator side of Y pulley plate 9 Remove the pulley plate ...

Страница 56: ...56 FormE 551 Lubrication Chart Below are the lubrication points for the Multi Ply Cutter ...

Страница 65: ...65 FormE 551 Additional Comments Maintenance Signature Date ...