4

®

The Eastman

SLS 2 Stack Labeler is shipped partially

disassembled with all the necessary parts for proper setup

and operation. To get the best performance, familiarize

yourself with all the functions and adjustments of this

equipment. Before any operation can take place, it is

important that you carefully read and follow the instructions

in this manual in the same sequence in which they are

presented.

INSTALLATION

Table Preparation

The spreading table required to operate your SLS 2 Stack

Labeler must be smooth and level. A minimum clearance of

24 inches (61 cm) is required from the table surface to the

floor and a minimum 3 feet (1 m) around the machine. If

Magna or Z-Track is required, install track at this time.

To Level Table

Use carpenter’s level to check spreading table. Be espe-

cially careful to make sure table joints mate closely. Adjust

table feet as necessary to level table.

Tracking Installation

The SLS 2 Stack Labeler requires Magna Track, Z-Track or

Guide Wheels to guide the machine.

Magna Track or Z- Track Installation

Place track sections along table top, end to end, on the

operator’s side of the table as they will be mounted. Mount

the track as shown. Make sure the joints in track are even

and DO NOT align with seams in table. Be sure track is

mounted firmly to table.

Place Machine on Table

The

SLS 2 Stack Labeler weighs approx. 400 lbs. (180 Kg.)

uncrated for a 60" machine. Wooden braces are

strapped across the underside of its cross channels and

the forklift arms should be raised to those braces when

machine is lifted.

CAUTION

When placing forklift arms under cross channels, use

care not to damage tension rods or cover.

When the

SLS 2 Stack Labeler is shipped the Stop Wands,

Stop Cams, Cable Carrier Kit and Guide Wheel Assemblies

are removed and must be installed upon installation.

Place the

SLS 2 Stack Labeler on table between end

markers (marks designating left and right end of spread).

Machines equipped with grooved wheels must be placed

on the lip of Magna or Z- Track.

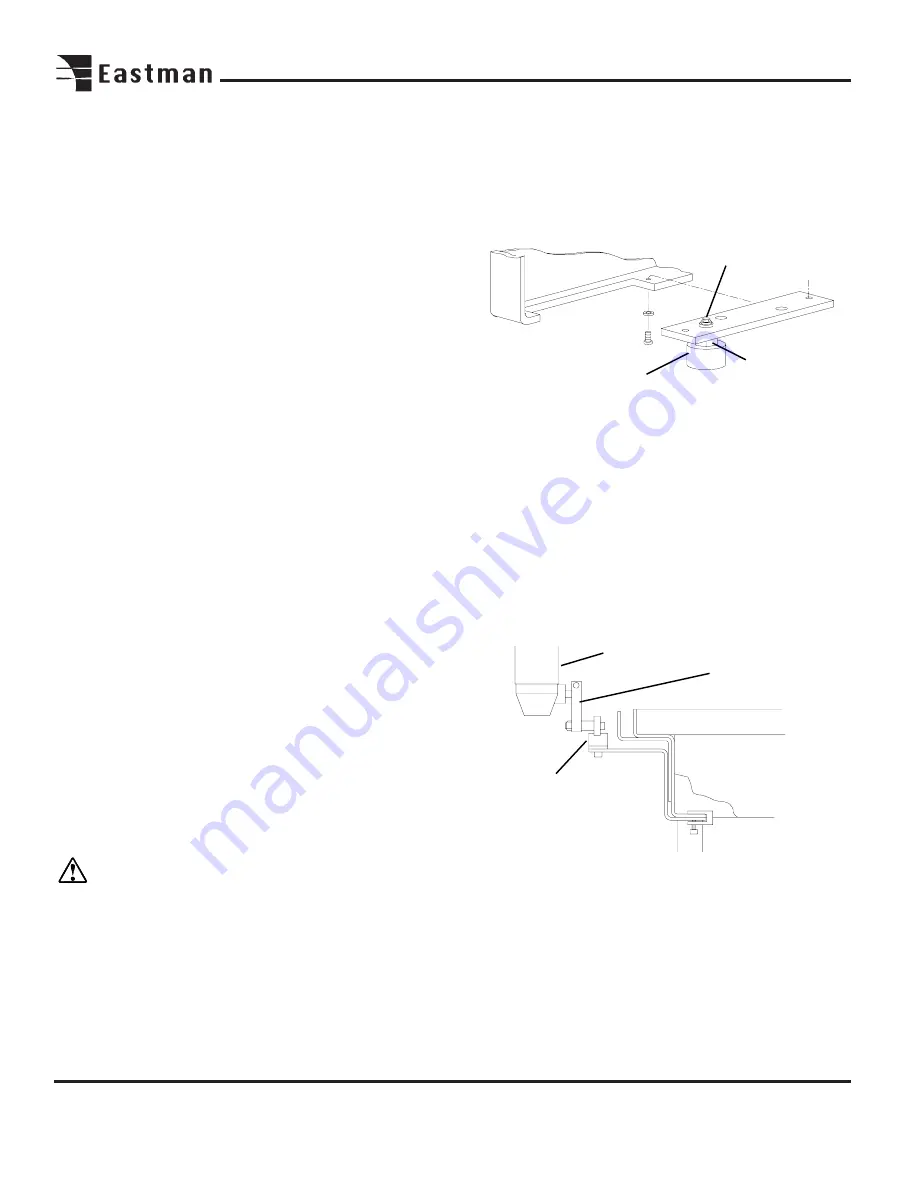

Guide Wheel

Assembly

Locking

Screw

Limit

Switch

Actuating

Arm

Safety Cam

Assembly

Guide Wheel Installation

Before installation can take place the covers must be

removed for access to the mounting holes. Remove the

mounting screws on the covers. Carefully remove the covers.

Mount the guide wheel assemblies as shown. To Adjust

Guide Wheels, Loosen the locking screw and turn the

adjusting nut until guide wheel makes contact with table. Do

not over tighten. If more adjustment is required, relocate

guide wheel in next hole. Tighten locking screw when

adjustment is complete.

Adjusting

Nut

Safety Cam & Home/Limit Switch Installation

The Safety Cams, Limit Switch, and Home Limit Switch

Assemblies should now be installed for safety. Mount the

Safety Cams as shown at each end of the spreading area.

Loosen the limit switch actuating arm and swing into posi-

tion. Secure actuating arm. Loosen the limit switch adjust-

ment plate and lower assembly to allow the actuating arm to

make contact with safety cam. If actuating arm does not

make contact with safety cam replace arm with longer arm

provided. Replace covers and secure the flat head screws.

Содержание ETS-SLS-2

Страница 1: ......

Страница 24: ...24 Notes ...

Страница 25: ...25 Notes ...

Страница 26: ...26 Notes ...

Страница 28: ......