22

Owner’s Manual

CHIPPER SHREDDER

Get parts online at

www.GetEarthquake.com

or Call

800-345-6007

M-F 8-5 CST

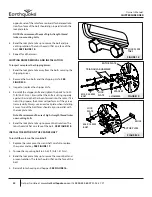

opposite side of the rotor faces outward for balanced rota-

tion. Two faces of the bolt should align in parallel with the

lock plate tabs.

NOTE: We recommend the use of high-strength thread

locker on mounting bolts.

4. Bend the lock plate tabs up to secure the bolt and pre-

venting rotation. The tabs should sit flat on a face of the

bolt. SEE FIGURE 18.

5. Repeat for all hammers.

CHIPPING KNIFE REMOVAL AND INSTALLATION

To inspect or replace the chipping knives:

1. Bend the lock plate tabs away from the bolts securing the

chipping knives.

2. Remove the two bolts and the chipping knife. SEE

FIGURE 20.

3. Inspect or replace the chipper knife.

4. Reinstall the chipper knife and tighten the bolts to 18-20

ft-lb (24-27 N.m.). Ensure that the knife is sitting squarely

against the stop that has been formed into the rotor. If it is

not sitting square, the knives will perform as if they are ex-

tremely dully. Always use a new lock plate when installing

knives. Two of the bolt faces should align in parallel with

the lock plate tabs.

Note: We recommend the use of high-strength thread locker

on mounting bolts.

5. Bend the lock plate tabs up to prevent bolt rotation. The

tabs should sit flat on a face of the bolt. SEE FIGURE 18.

INSTALL THE ROTOR ON THE CRANKSHAFT

To install the rotor on the crankshaft:

1. Replace the rotor onto the crankshaft, careful to replace

the spacer and key. SEE FIGURE 17.

2. Torque the mounting bolt to 30-35 ft-lb (41-47 N.m.).

3. Bend the lock plate tabs up to secure the mount bolt and

prevent rotation. The tabs should sit flat on the face of the

bolt.

4. Reinstall rotor housing and hopper. SEE FIGURE 16.

FIGURE19

FIGURE 20

TRIANGULAR-HAMMER

M10 X 50 MM

BOLT

LOCK

PLATE

J-HAMMER

ROTOR PLATE

ROTOR PLATE

KNIFE

FIGURE 18

LOCK PLATE

TABS

SPACERS

LOCK

PLATE

M8 X 16 MM

BOLT