18

Owner’s Manual

CHIPPER SHREDDER

Get parts online at

www.GetEarthquake.com

or Call

800-345-6007

M-F 8-5 CST

CHECK FOR LOOSE HARDWARE

Service Interval: Every 5 hours; every spring and fall.

Inspect the unit, checking for loose hardware or components.

Pay special attention to the hardware attaching the chipper

cone, hopper, axle, and front leg.

CHECK SAFETY LABELS

Service Interval: Every spring and fall.

Check that the safety labels are in place and undamaged.

Replace any damaged or missing decals.

INSPECT CONE, HOPPER AND GUARDS

Service Interval: Every spring and fall.

Check that the chipper cone, shredder hopper, and discharge

guards are in place, undamaged, and secure. Replace any

damaged or missing parts.

CLEAN DEBRIS FROM ENGINE AND CHIPPER

Service Interval: Before each use and every 100 hours.

The engine requires air flow to cool itself and for combustion.

Before each use, clean any debris from the unit especially from

around the air shroud intake, air filter, and muffler. Every 100

hours, remove the engine air shroud and clean out any debris

from the engine cooling fins SEE FIGURE 10. We recommend

having this service performed by an authorized repair center.

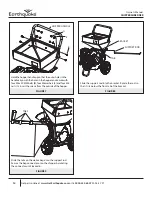

INSPECT / ROTATE SHREDDING HAMMERS

Service Interval: Every 25 Hours, or As Necessary

The shredding hammers of this unit can be rotated to provide

a new cutting surface as required. The triangular hammers

can be rotated twice, then flipped over for a total of 6 sharp

cutting surfaces. The J-hammers can be flipped over once. To

inspect the shredding hammers:

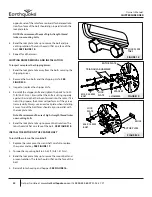

1. Disconnect the spark plug wire and secure it away from

the spark plug. SEE FIGURE 14

(on page 19).

2. Remove the small circular access panel (B) from the back

of the shredder housing. SEE FIGURE 11.

3. Inspect the cutting edges of the triangular hammers (A)

and J-hammers (A). SEE FIGURES 11 AND 12.

To rotate or replace the shredding hammers, see the Trouble-

shooting and Repair section.

FIGURE 10

FIGURE 11

FIGURE 12

J-HAMMER

WEAR AREA

ACCESS PANEL

TRIANGULAR-HAMMER

WEAR AREA

MUFFLER

AIR

SHROUD

INTAKE/

AIR FILTER

DEBRIS OFTEN GATHERS IN

THIS AREA

COOLING FINS