Installation, Operation and Parts Manual

EE-6214EKZ

24

MAINTENANCE

Easy and low cost routine maintenance can ensure the lift work normally and safely. Following are requirements for routine maintenance.

Follow the below routine maintenance schedule with reference to the actual working condition and frequency of your lift.

S/N

Components

Methods

Period

1

Swing arm locking units

Push the UP button to raise the lifting arms and check if four

swing arms are locked into position. Add grease in case

necessary.

Every day

2

Rubber contact pads

Inspect the pads and clean off any objects that may cause

sliding or damage.

Every day

3

Cylinder and oil hose connectors Inspect to ensure no leakage before using the lift.

Every day

4

Control buttons

Check if control buttons work as "hold- to -run " and check if

they work as the function indicated.

Every day

5

Mechanical safety locking unit

Check if both mechanical catches can engage and disengage

simultaneously by pushing control buttons.

Every day

6

Limit switch

Push the UP button and inspect and to ensure the lifting

platform stops rising when the switch is activated.

Every day

7

Unloading valve

Inspect if the valve leaks or not. Clean or change the valve if it

leaks.

Every day

8

Steel cables

Check the synchronization of both carriages and adjust the

tightness of the cable if desynchronization is unacceptable.

Every day

9

Bushing of the upside pulley and

circlip of the shaft

Lubricate the bushing with NO.1 lithium based grease.

Check if the circlip is in its original position.

Every 3 months

Содержание EE-6214EKZ

Страница 10: ...Installation Operation and Parts Manual EE 6214EKZ 10 3 4 Dimensions...

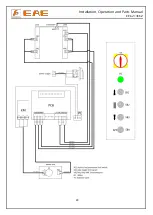

Страница 27: ...Installation Operation and Parts Manual EE 6214EKZ 27 Annex 2 Electrical schemes and parts list...

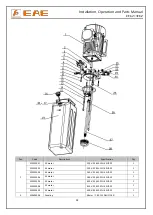

Страница 28: ...Installation Operation and Parts Manual EE 6214EKZ 28...

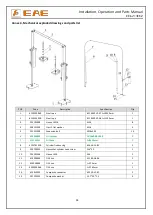

Страница 29: ...Installation Operation and Parts Manual EE 6214EKZ 29...